Hot-Dip Galvanized Steel Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

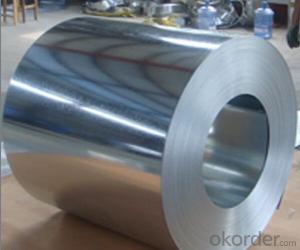

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: What are the different types of steel coil packaging materials used during processing?

- Some of the different types of steel coil packaging materials used during processing include steel strapping, plastic strapping, stretch film, shrink wrap, and coil covers.

- Q: That's my question, well that and:Steel Pick + Electric Guitar = Trashed Guitar?:D

- Uh. . . your guitar would be okay. . . except your strings wouldn't last long then nylon strings.

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- Kera...time to crank up the brain in gear....molten refers to what state of matter? Solid, Liquid, Gas, Plasma? Ding-Ding-Ding....liquid. Solid to liquid is the melting point.

- Q: Im getting a new guitar soon, and it has steel strings. ive heard that nilon strings are better? thanks:)

- Nylon is allegedly better for beginners because they don't cut into the fingers as much. Steel sounds much better, though.

- Q: I know that steel is generally iron with carbon and probably some other things in it, but I'm doing a research paper on architecture in Tokyo, and touching on the Tokyo Tower.The Tokyo work is larger than the Eiffel Tower by 12 meters, but lighter by 3000 tons. The only reason I can find for the difference in weight is that the Tokyo Tower is made of steel and the Eiffel Tower in made of iron, and since the Tokyo Tower is modeled after the Eiffel, there's really not a substantial difference in the amount of metal used....

- Steel Lighter

- Q: What is future prospect of these steel structures, are they really weather proof like everyone believes??

- Yes okorder /

- Q: what is the difference between metal and steel

- well, steel is a type of metal. It's sort of like asking the difference between a bug and an ant, an ant is a bug, but not every bug is an ant. Likewise, steel is metal, but not all metal is steel. Gold is metal, Silver is metal, Iron is metal, Steel is metal.

- Q: What are the different types of steel coil slitting knives?

- There are several different types of steel coil slitting knives, including circular slitting knives, straight slitting knives, and crush-cut slitting knives. These knives are used for precision cutting and slitting of steel coils into narrower strips or sheets. Circular slitting knives feature a circular shape with sharp edges, while straight slitting knives have a straight cutting edge. Crush-cut slitting knives have a unique design that allows them to crush and cut the material simultaneously. Each type of knife is used for specific applications and offers different advantages depending on the desired outcome.

- Q: How do steel coils contribute to the construction equipment industry?

- The construction equipment industry relies heavily on steel coils as they are vital for manufacturing various construction machinery and equipment. These coils, made from high-quality steel, are crucial components used in the fabrication of a wide range of construction equipment, including cranes, bulldozers, excavators, loaders, and forklifts. The main contribution of steel coils to the construction equipment industry lies in their structural strength and durability. Steel is renowned for its exceptional mechanical properties, such as high tensile strength, toughness, and resistance to wear and corrosion. These properties make it an ideal material for constructing heavy-duty machinery capable of withstanding the demanding conditions of construction sites. Steel coils are employed in the production of the structural components of construction equipment, such as chassis, frames, booms, buckets, and attachments. These components need to be sturdy and able to endure heavy loads, impacts, and continuous use. Steel coils provide the necessary strength and reliability to ensure the long-lasting performance of construction equipment. Moreover, steel coils are also used to manufacture specialized parts and accessories for construction machinery. These include hydraulic systems, gears, shafts, bearings, and fasteners. These components are essential for the proper functioning and efficiency of construction equipment, and steel coils provide the high-quality material required for their production. In addition to their mechanical properties, steel coils also contribute to the construction equipment industry through their versatility and customization options. Steel can be easily shaped, cut, welded, and formed into various sizes and shapes, allowing manufacturers to create equipment with specific designs and functionalities tailored to meet the diverse needs of construction projects. Overall, steel coils are indispensable in the construction equipment industry as they serve as the foundation for robust and reliable machinery. Their strength, durability, and versatility make them an essential raw material for manufacturing construction equipment that can withstand the challenges of construction sites and ensure the safety and efficiency of construction projects.

- Q: What is the role of steel coils in the electrical industry?

- The role of steel coils in the electrical industry is significant as they serve multiple purposes in various applications. Steel coils are used as components in transformers, which are essential for power distribution and voltage regulation. These coils are responsible for transferring electrical energy from one circuit to another, allowing for efficient transmission of electricity across long distances. Additionally, steel coils are utilized in the production of electric motors and generators. They are wound around the stator and rotor to create magnetic fields, which enable the conversion of electrical energy into mechanical energy and vice versa. This process is crucial in various industries, including automotive, manufacturing, and renewable energy sectors. Steel coils also play a role in the production of electrical cables and wiring. They are used to provide strength, durability, and protection to the conductive copper or aluminum wires within the cables. These coils are responsible for maintaining the structural integrity of the cables, ensuring safe and efficient transmission of electricity. Furthermore, steel coils find application in electrical equipment such as solenoids and relays, where they help create magnetic fields to control the flow of electrical current. They are also used in various electrical appliances, including refrigerators, air conditioners, and televisions, where they act as essential components in the functioning of these devices. In summary, steel coils have a vital role in the electrical industry. They are used in transformers, motors, generators, cables, and various electrical equipment, contributing to the efficient distribution, conversion, and transmission of electrical energy.

Send your message to us

Hot-Dip Galvanized Steel Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords