Hot-Dip Galvanized Steel Coil Used for Industry with Much Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

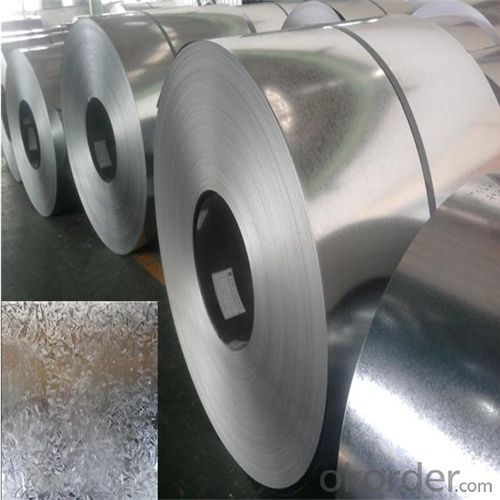

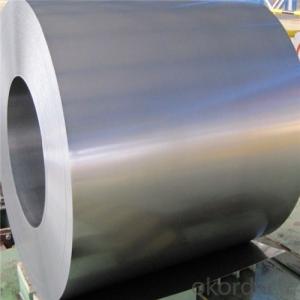

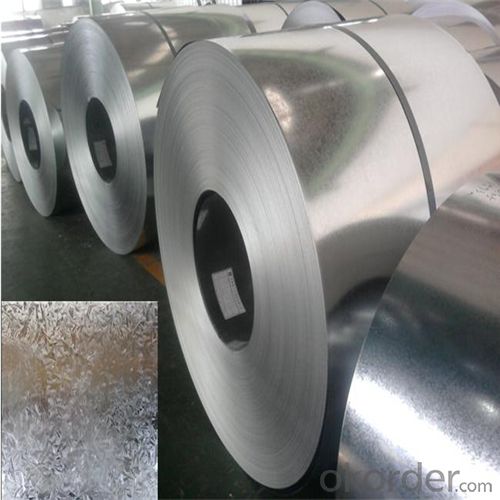

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How do steel coils contribute to the renewable energy equipment industry?

- Steel coils play a crucial role in the renewable energy equipment industry by being a key component in the manufacturing of various renewable energy technologies. One of the primary applications of steel coils is in the production of wind turbines. The tower, nacelle, and rotor blades of wind turbines all require steel coils for their construction. In the manufacturing of wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support to the turbine. These coils are typically rolled and welded together to form the tower, ensuring its strength and durability to withstand the forces exerted by the wind. Additionally, steel coils are also used to produce the nacelle, which houses the generator and other essential components of the wind turbine. Moreover, steel coils are used in the production of rotor blades for wind turbines. These blades are responsible for capturing the wind and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength and rigidity to withstand the aerodynamic forces. The coils are often combined with composite materials to optimize the performance and efficiency of the blades. Apart from wind turbines, steel coils are also used in other renewable energy technologies such as solar panels. In the manufacturing of solar panels, steel coils are used to create the frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to efficiently capture sunlight and convert it into electricity. Overall, steel coils are vital in the renewable energy equipment industry as they provide the necessary strength, durability, and structural support to various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector, thereby advancing the global transition towards cleaner and more sustainable sources of energy.

- Q: Hello, Do I make any damage to my stainless steel sink by cleaning it with clorox? Thank you!

- I think not. I owned stainless steel sinks before that were they were in style. I used Clorox and more on them and they always turned out great. found wiping them out with a paper towel made them shine.

- Q: What are the different types of steel coil processing equipment?

- There are several different types of steel coil processing equipment, including coil slitting machines, coil cut-to-length machines, coil leveling machines, and coil edge trimming machines. Each of these machines serves a specific purpose in the steel coil processing industry, helping to efficiently and accurately cut, shape, and prepare steel coils for various applications.

- Q: how come when i put steel legs in lowest price in grand exchange no one buys them i got 101 steel legs in there and there at lowest price and they have been there for 3 days

- Becuase you should sell something else.

- Q: What dangers were there for the steel workers in Pittsburgh under Carnegie?

- Same as other steel plants, getting crushed by falling steel, getting burned by hot metal etc

- Q: What are the factors that affect the price of steel coils?

- There are several factors that influence the price of steel coils. Firstly, the cost of raw materials such as iron ore and coal, which are essential for steel production, can significantly impact the price. Additionally, the demand and supply dynamics of steel in the market play a crucial role. Factors like economic growth, construction activity, and infrastructure development can drive up the demand for steel, leading to price increases. On the other hand, if there is excess supply or reduced demand, prices may decrease. Moreover, fluctuations in energy costs, transportation expenses, and currency exchange rates can also affect the final price of steel coils.

- Q: What are the uses of galvanized steel coils?

- Galvanized steel coils have a wide range of uses in various industries due to their unique properties. Here are some common uses of galvanized steel coils: 1. Construction: Galvanized steel coils are widely used in the construction industry for various applications. They are used to manufacture roofing sheets, wall panels, and structural components. The galvanized coating helps to protect the steel from corrosion, extending its lifespan and ensuring durability in harsh weather conditions. 2. Automotive industry: Galvanized steel coils are used in the automotive industry for manufacturing different parts and components. These coils are used to manufacture body panels, chassis, and other structural parts of vehicles. The galvanized coating provides excellent corrosion resistance, which is crucial for the longevity of automobiles. 3. Appliances: Galvanized steel coils are used in the production of various household appliances, such as refrigerators, washing machines, and air conditioners. The coils are used to manufacture the outer panels and cabinets of these appliances, providing them with a strong and durable structure. 4. Agriculture: Galvanized steel coils find applications in the agriculture sector as well. They are used to manufacture agricultural equipment, such as grain storage silos, irrigation systems, and livestock enclosures. The galvanized coating protects the steel from rust and corrosion, ensuring the safety and longevity of these agricultural structures. 5. Industrial applications: Galvanized steel coils are widely used in various industrial applications. They are used for manufacturing ductwork, ventilation systems, and industrial piping. The galvanized coating helps to resist chemicals, moisture, and other environmental factors, making it an ideal choice for industrial environments. 6. Electrical industry: Galvanized steel coils are used in the electrical industry for manufacturing electrical enclosures, conduit pipes, and cable trays. The galvanized coating provides excellent protection against corrosion and ensures the safety and durability of electrical installations. 7. Furniture manufacturing: Galvanized steel coils are used in the furniture manufacturing industry for producing furniture frames, shelves, and cabinets. The galvanized coating adds strength and durability to these furniture pieces, making them long-lasting and resistant to corrosion. Overall, galvanized steel coils have a wide range of uses in various industries due to their excellent corrosion resistance, durability, and strength. They are a cost-effective and reliable choice for applications that require protection against rust and environmental factors.

- Q: As we all know Shaq killed the movie Steel by suckin so bad but does anyone know what happened to the comic book version.

- Steel's own series was cancelled around issue #50, after which he went on to a co-starring role in Superman: The Man of Steel. Steel was eventually injured in a battle with Darkseid, at which time his niece Natasha took on the role of Steel. John Henry recently resurfaced in his heroic identity in 52, where he's been injected with Lex Luthor's metagene, making his body living stainless steel.

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include a growing demand for high-strength and lightweight steel coils, increased focus on sustainability and recyclability, advancements in technology for improved efficiency and productivity, and a shift towards automation and digitalization in manufacturing processes. Additionally, there is a rising preference for customized steel coil solutions to meet specific industry requirements.

- Q: Hey guys do you know anything about Steel Arch Building and how this structure really looks like?

- i think a moment frame steel building with a parabolic arch from two corners with the top middle capstone looks pretty nice on four sides. on a plane view, the capstone forms a cross on roof top with a rectangular elevator shaft at middle and with several floors act as weight on the capstone. the four corners roof top floors have to have heavy columns reaching down to the foundation. then u draw a inverted V from the root of the arch to the capstone and filled the area between the arch and inverted V with trussed web members. this trussed arch can act as a wind bracing for the moment frame building. u have to investigate the proper angles for the trussed web members. if u set a vertical web member from the arch to the inverted V, that is at the largest gap and then build the truss web member from there. i would not only use one facade but double facade to increase the capacity of the building to resist vertical and lateral loads. however, the arch needs a tie beam to make sure the roots of the arch won't spread apart under compressive load and the load must be contain inside the arch. no one has build one like that yet.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Much Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords