Hot-Dip Galvanized Steel Coil Used for Industry with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

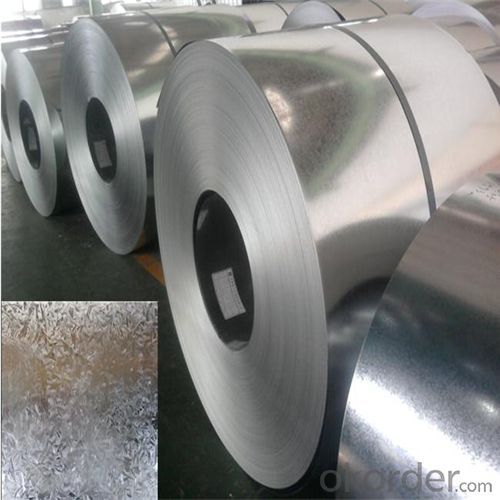

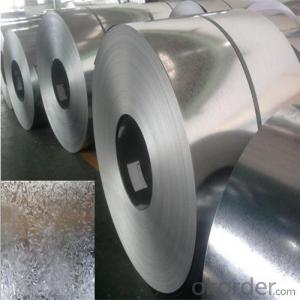

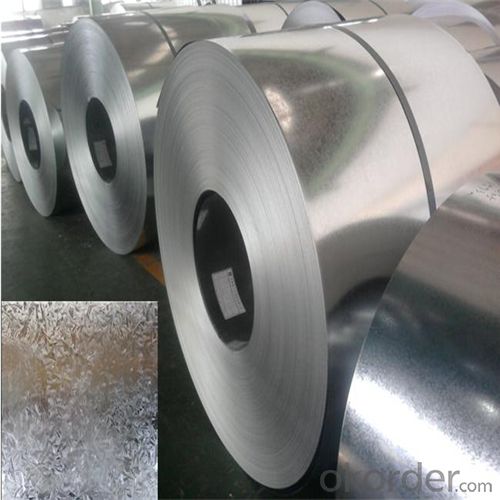

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners as they serve as the raw material for manufacturing various types of fasteners such as screws, bolts, nuts, and washers. The steel coils are unwound and then processed through machinery that cuts, shapes, and forms them into the desired fastener shape. This allows for efficient and precise production of steel fasteners, ensuring their strength, durability, and compatibility with various applications.

- Q: What are the advantages of using steel coils in construction?

- Using steel coils in construction offers several advantages. Firstly, they possess immense strength and durability, enabling them to withstand heavy loads and resist deformation. As a result, they are perfect for structural purposes such as beams, columns, and frames. Secondly, steel coils exhibit exceptional versatility. They can be easily shaped and molded into various forms, providing flexibility in design and construction. Steel coils can be rolled, bent, cut, and welded according to specific project requirements. This adaptability makes them suitable for a wide range of construction applications. Another benefit of utilizing steel coils in construction is their resistance to corrosion. To prevent rusting and corrosion, steel coils are often coated with protective substances like galvanized or stainless steel. This ensures that the building's structural integrity remains intact over time, even in harsh environmental conditions. Furthermore, steel coils offer excellent fire resistance. Unlike materials such as wood, steel does not burn or contribute to the spread of fire. Hence, it is a safer option for construction, especially in high-rise buildings or areas prone to fire hazards. Lastly, steel coils are cost-effective. Although the initial cost of using steel coils may be higher compared to other materials, their longevity and low maintenance requirements make them a cost-efficient choice in the long run. Steel coils have a long lifespan and necessitate minimal repairs or replacements, resulting in reduced maintenance costs and increased overall value. In conclusion, the advantages of using steel coils in construction encompass their strength, versatility, corrosion resistance, fire resistance, and cost-effectiveness. These qualities make steel coils an outstanding choice for various construction applications, contributing to the durability and safety of buildings.

- Q: My neighbor who has an older model mustang installed a steel clutch in it and has blown 4 transmissions as a result.Can any mechanic explain why a steel clutch would kill transmissions? What other modifications would the car need in order to prevent this?

- figger he would learn after a tranny or two...no reasion for any clutch to wreck a tranny.must b bad instalation..or he cant drive

- Q: Are steel buildings or homes better then wooden buildings? Why?

- Steel is better than wood. Steel can support more weight than wood. Steel is also much more durable than wood. Termites and rot are not a problem, which results in lower maintenance cost later. Also, wood can rot and warp whereas steel will not. Steel is also more economical than wood. The construction requires less labor, and as a result the labor cost is much lower. Steel is fire resistant, which will lower insurance costs.

- Q: What are the common methods of slitting steel coils?

- There exists a variety of methods for slitting steel coils, each possessing their own distinct advantages and applications. 1. Rotary Shear Slitting: This technique utilizes rotary cutting knives to separate the steel coil. The coil is passed through the rotary shear machine, and the knives make simultaneous cuts along the coil's length. Rotary shear slitting is renowned for its high-speed operation and ability to handle thicker gauge materials. 2. Loop Slitting: Loop slitting involves introducing the steel coil into a looping pit, creating a loop of material. The loop is then pulled through a set of knives that make the cuts. This particular approach is commonly employed for thin gauge materials, providing precise cuts with minimal burr. 3. Drag Slitting: In drag slitting, the steel coil is fed through a series of driven rolls or drag pads, which maintain tension on the material. The coil is then guided through circular knives that perform the slits. Drag slitting is suitable for various steel gauges and offers good accuracy and edge quality. 4. Crush Slitting: Crush slitting entails passing the steel coil through a set of rolls, with one roll being rubber-covered and the other being hard. The rubber roll compresses the material against the hard roll, resulting in the slits. This method is commonly utilized for thin gauge or delicate materials, as it minimizes the risk of edge damage. 5. Laser Slitting: Laser slitting employs a high-powered laser beam to make precise cuts on the steel coil. This method is highly accurate and enables complex slitting patterns and narrow width cuts. Laser slitting is frequently utilized for high-end applications that demand superior edge quality. Each of these methods possesses unique advantages and is selected based on factors such as material thickness, desired edge quality, production speed, and cost considerations. It is crucial to meticulously select the appropriate slitting method to ensure the desired outcome and efficiency in steel coil processing.

- Q: How are steel coils used in the production of heating systems?

- Steel coils are used in the production of heating systems in various ways. One of the main uses of steel coils in heating systems is in the construction of heat exchangers. Heat exchangers play a crucial role in transferring heat from one medium to another within the heating system. The steel coils are typically formed into a series of tubes or fins, which provide a large surface area for efficient heat transfer. In a typical heating system, hot gases or liquids pass through these steel coils, while another medium, such as air or water, flows over or through the coils. This allows for the transfer of heat energy from the hot medium to the cooler medium, thereby effectively heating the air or water for distribution throughout the heating system. Another use of steel coils in heating systems is for the production of radiant heating panels or floor heating systems. In these applications, the steel coils are typically embedded within a panel or underneath the flooring. When electricity or hot water is passed through the coils, they heat up, radiating heat to the surrounding environment. This type of heating system is particularly efficient and provides a comfortable and even distribution of heat. Furthermore, steel coils are also used in the manufacturing of heating system components such as boilers, furnaces, and heat pumps. These components often require the use of steel coils for their heat transfer capabilities and durability. The coils are integrated into the design of these heating system units to ensure efficient and reliable heat generation and distribution. Overall, steel coils play a crucial role in the production of heating systems by enabling efficient heat transfer, providing durability, and facilitating the generation and distribution of heat.

- Q: Does anyone know how to make a steel helmet, or does anyone know where to direct me websites-wise? i've just started looking on the web for info, so when i get back here i might've already found some info, but more wouldn't hurt, especially if from people who are interested on the subject. i know nothing about metallurgy, nothing on the art of metal working etc... please help.

- Steel okorder

- Q: How are steel coils processed?

- Steel coils are processed through a series of steps that include uncoiling, levelling, cutting, and recoiling, ensuring the steel is transformed into the desired shape and size for various applications such as construction, automotive, and manufacturing industries.

- Q: What are the different grades of steel used in coils?

- There are several different grades of steel used in coils, including low carbon steel, high carbon steel, stainless steel, and alloy steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, durability, corrosion resistance, and formability.

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- No. Not quite. The term 'Hardened steel' is often used to refer to 'Heat treated steel'. There are two separate steps in heat treatment. First the red hot steel is 'quenched' (rapidly cooled). This yields maximum hardness ,but the steel may be too brittle for the intended purpose. The next stage, 'tempering' is heating to a limited temperature, and slow cooling. This reduces the hardness somewhat, depending on the re-heat temperature, but restores some of the toughness lost in the first stage.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords