Hot-Dip Galvanized Steel Coil of High Quality with Different Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

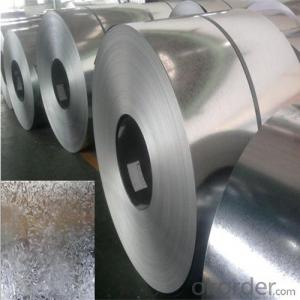

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Type: Steel Coil

Surface Treatment: chromated, oiled, skin-pass

Application: Container Plate, panel sandwich

Special Use: High-strength Steel Plate

width: 600-1500mm

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

1.What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

2.Which payment term we can do?

L/C at sight or T/T.

3.Where is our factory?

Near by Tianjin and Shanghai.

4. What is the mininum quantity of every order?

50 tons.

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include a protective zinc coating that prevents corrosion, high strength and durability, excellent formability and weldability, and a smooth and shiny surface finish.

- Q: what is the difference between METAL and STEEL?

- Metal is the generic name for several pure chemical elements and they alloys that can be made from them. Steel is used to designate alloys that consist mainly of iron, with a limited proportion of carbon in them.

- Q: What are the different methods of engraving steel coils?

- There are several methods of engraving steel coils, including laser engraving, chemical etching, mechanical engraving, and electrochemical etching. Each method involves different techniques and tools to create precise and permanent markings on the surface of the steel coils.

- Q: I need to know how you rate the hardness of steel any ideas?

- Find your portable hardness testers from our latest collections thats for sure having the ability to test hardness of metal alloys and plastic by applying some amount of pressure on it. All our evaluators can evaluate in Brinell, Rockwell and Vickers machines.

- Q: is a 1962 steel penny worth anything?

- Is this an american penny? If it is, it is copper. They only made steel pennies in 1943. Someone claims they have seen a rare 1944, but who really knows? A 1962 will be worth a penny unless it is part of a mint or proof set. During WW II, all 1943 U.S. cents were struck in zinc-finished steel instead of copper. The copper saved from this one-year issue was used in the war effort, mainly in the manufacture of shell casings. Most of the so calledsteelies were minted in Philadelphia, but some steel pennies were struck in Denver, and San Francisco. Edit Brandi: If it is steel it will stick to a magnet. It truly sounds like you have a discolored penny. This can happen with exposure to different chemicals and even machine washing. The D means that it was minted in Denver You can view a lot of different coin collection samples on OKorder. The values are consistent with expert numismatic pricing. I strongly feel you have a 1962 copper penny.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: Got small (.177) bb gun for fun with my son...From the manual:'Steel shot will fire at a higher velocity then lead shot with with the same muzzle energy. As a result, more caution is required when using steel shot because of a greater hazard of ricochet. Lead, because of its lower velocity, usually has less penetrating power and is less likely to ricochet.'Are you agree with that? ;)

- steel is made of iron mainly (and carbon) its density is 7.86 g/cm? approximately. and lead has density=11.4 g/cm?. so, if have same volume and shape steel will have less mass and thus will have greater velocity for same muzzle energy. I agree the manual. for more information on ricochet

- Q: Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Stainless can oxidize over time but it doesn't look much like regular rust. Depending on the exact composition of the stainless alloy in question and what other materials are in contact with it, that's more or less of an issue. In constant contact with skin oils and gentle polishing from contact with skin and clothing, watches rarely rust regardless of what they're made of, I think you have nothing to worry about. Note: for future reference, bleach is absolute hell on stainless. It's bad enough on steel, worse on stainless. Especially because you have this idea that stainless is more or less impervious, when in reality it just isn't.

- Q: I have a steel string, Yamaha acoustic guitar that I am learning to play at home. But at school I use a rented nylon string guitar. I like the feel of the nylon strings better then the steel strings and i was wondering if i can just switch strings or if i should just get another guitar. Can anyone help?

- No, a steel string guitar is built and braced for the greater tension of steel strings, which means it's too heavily built to respond properly to nylon strings. It would sound awful. Besides, the slots in the nut are too narrow on a steel-string, the action is too low, and the bridge is made for ball end strings (most high quality nylon strings are plain end). And you would have to turn the narrow string posts on steel-string tuners forever to get anywhere with stretchy nylon strings.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- The 2 objects will have the same size and shape. Therefore they will have the same air resistance. So the heavier object (the sheet of paper) will reach the ground first.

Send your message to us

Hot-Dip Galvanized Steel Coil of High Quality with Different Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords