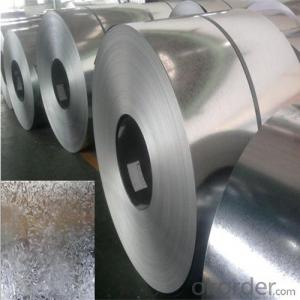

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | China (Mainland) | Brand Name: | N/M | Model Number: | ssp-226 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include their high corrosion resistance, durability, and ability to withstand extreme weather conditions. They are also known for their excellent formability, making them suitable for various applications in construction, automotive, and manufacturing industries. Additionally, galvanized steel coils have a smooth and shiny appearance due to the zinc coating, which provides aesthetic appeal along with enhanced protection against rust and other damages.

- Q: What are the different types of steel coil packaging machines?

- There are several different types of steel coil packaging machines available in the market. These machines are designed to efficiently and effectively package steel coils for storage, transportation, or distribution. Some of the different types of steel coil packaging machines include: 1. Automatic steel coil packaging machine: This type of machine is fully automated and can handle high-volume packaging requirements. It uses advanced technology to wrap the steel coils with a protective layer of film or paper. The machine can also apply strapping or stretch film to secure the coils during transportation. 2. Semi-automatic steel coil packaging machine: This machine requires some manual intervention to load and unload the steel coils. It is suitable for medium to high-volume packaging needs and offers a good balance between automation and cost-effectiveness. The machine typically uses a combination of wrapping, strapping, and shrinking techniques to package the coils. 3. Vertical steel coil packaging machine: This type of machine is designed specifically for packaging vertical steel coils. It can wrap the coils with a layer of film or paper, and then apply strapping or stretch film to secure them. The vertical design allows for easy loading and unloading of the coils. 4. Horizontal steel coil packaging machine: This machine is ideal for packaging horizontal steel coils. It can wrap the coils with a protective layer of film or paper, and then apply strapping or stretch film to secure them. The horizontal design ensures easy loading and unloading of the coils. 5. Customized steel coil packaging machine: Some manufacturers offer customized packaging solutions based on specific requirements. These machines can be tailored to accommodate different coil sizes, shapes, and packaging materials. They are designed to provide maximum flexibility and efficiency in the packaging process. In summary, the different types of steel coil packaging machines include automatic, semi-automatic, vertical, horizontal, and customized machines. The choice of machine depends on factors such as packaging volume, coil orientation, and specific requirements of the steel coils being packaged.

- Q: I heard on some shows that you can carbonise steel by heating it red hot then dropping it in black oil. i cant find this no where online, and the process for commercial carbon steel is totally different. can you really carbonise regular steel by heating it to red hot then dropping it in regular black oil. i saw it on mythbusters once. when the made carbon steel hammers to test if 2 hammers smashed together will shatter

- in the experience that your speaking a pair of folding pocket knife, i think of that it somewhat is somewhat six one way and a 0.5 dozen the different. i actually do choose stainless for my pocket knives. i don't choose to grease a knife to the degree i've got faith carbon demands, basically to then stick it my pocket to entice dirt to the knife and oil to my pants. i'm the impressive opposite on sheath knives nevertheless. i admire 1095 carbon steel, uncomplicated part sheath knives. i will thrash on them difficult, and that i rarely have considerable part issues. of course, I require them to be lined with some style of powder coat or the like, with the aid of fact they might rust, yet I do attempt and save them sparkling and dry whilst in the sheath, so as that they gained't pit the uncoated part. My motives for this sheath knife selection is multi-fold. First, those knives are only much less costly. i don't spend $80 money on a exterior sheath knife. i take advantage of the gadget too difficult to choose to spend extra. i don't basically like the extra classic stainless steels alongside with AUS-8, 420HC, and 440C (to not point out the HORRENDOUS 440A) with the aid of fact i've got faith that the all else being equivalent, a stainless blade will bend till now a carbon blade will harm. I additionally think of that carbon holds an part a minimum of besides, if not extra suited, than classic stainless, and it somewhat is plenty extra handy to hone. i don't understand plenty approximately those new laminates, different than the very difficult, yet not so difficult. they seem probably too brittle for my use. That, mixed with the actuality that they harm the bank, ability that I only is only not pondering them.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: How much do steel coils weigh?

- The weight of steel coils is subject to variation, which is determined by multiple factors including coil thickness, width, length, and the particular type of steel employed. In general, steel coils can range in weight from a few hundred pounds to several tons. It should be emphasized that the measurement of steel coils typically revolves around their weight per unit area, referred to as the "basis weight" or "coil weight".

- Q: Can steel coils be coated with anti-graffiti materials?

- Yes, steel coils can be coated with anti-graffiti materials. These materials create a protective layer that can prevent graffiti from adhering to the surface, making it easier to remove any unwanted markings.

- Q: I play the guitar and recently found a new type of a guitar called the steel guitar, I don't want to play it or anything it's just I've never seen anything like it before and wonder what the function of it is and what are the differences to a classical guitar

- There okorder /

- Q: what is the difference between metal and steel

- well, steel is a type of metal. It's sort of like asking the difference between a bug and an ant, an ant is a bug, but not every bug is an ant. Likewise, steel is metal, but not all metal is steel. Gold is metal, Silver is metal, Iron is metal, Steel is metal.

- Q: I have a tiara and it oxidized and I'm not sure what material it is. I know it it isn't metal so i was wondering if is steel? Also if it's steel, can I do something to clean it?

- Yes - Steel can oxidize, its most commonly called rust Steel is a metal. Depending on the level of oxidation, you might be able to polish it with very fine steel wool. If is is really bad, then you might need a chemical cleaner such as Naval Jelly, which can be found at the hardware store. But the Naval Jelly might discolor the metal, so then you might need to polish it afterward to return its finish.

- Q: How are steel coils used in the production of metal roofing panels?

- Steel coils are a critical component in the production of metal roofing panels. These coils, which are rolled sheets of steel, play a crucial role in shaping and forming the panels. To start with, the steel coils are unwound and fed into a machine called a roll former. This machine uses a series of rollers and dies to gradually shape and bend the steel into the desired profile of the metal roofing panel. The coils pass through these rollers, which apply pressure and force to mold the steel into the required shape and size. Once the metal has been formed into panels, it may undergo additional processes to enhance its durability and appearance. This can include galvanizing or coating the panels with various protective layers to prevent corrosion and improve weather resistance. These additional steps help to ensure that the metal roofing panels are able to withstand harsh environmental conditions and provide long-lasting performance. Steel coils are preferred in the production of metal roofing panels due to their strength and durability. Steel is known for its exceptional strength-to-weight ratio, making it a suitable material for roofing applications. Additionally, steel is highly resistant to various weather conditions, including high winds, heavy rains, and extreme temperatures. This makes it an ideal choice for roofing panels that need to withstand the elements and provide reliable protection for buildings. Overall, steel coils are an essential component in the manufacturing process of metal roofing panels. They are used to shape and form the panels, which are then further processed to enhance their durability. The use of steel in these panels ensures that they can withstand harsh weather conditions and provide long-lasting performance for residential, commercial, and industrial buildings.

Send your message to us

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords