Hot Dip Galvanized Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Galvanized Steel Building Roof Walls

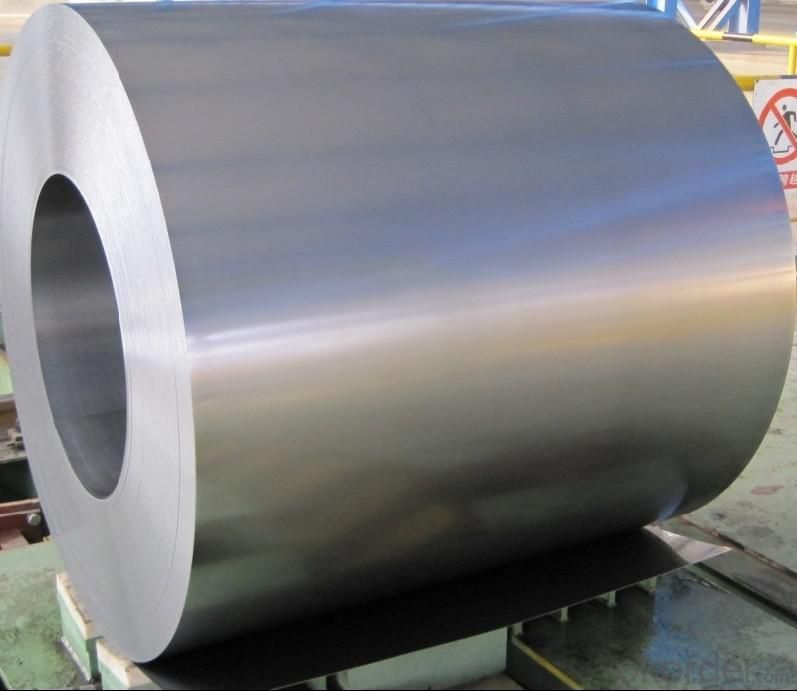

1.Structure of Hot-Dip Galvanized Steel Sheet or Coil:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of Hot-Dip Galvanized Steel Sheet or Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

3.Images of Hot-Dip Galvanized Steel Sheet:

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the common methods of packaging steel coils for international shipping?

- There are several common methods of packaging steel coils for international shipping. These methods are designed to ensure the safety and security of the coils during transit. One method is the use of wooden crates. The steel coils are placed on wooden pallets and secured with steel bands or straps. The coils are then covered with wooden boards or plywood and nailed or screwed in place to create a sturdy crate. This method provides excellent protection against damage and ensures that the coils remain in place during transportation. Another method is the use of steel frames or skids. The steel coils are placed on steel skids or frames that are designed to support the weight and shape of the coils. The coils are then secured to the skids or frames with steel bands or straps. This method offers a high level of stability and protection, and is commonly used for larger or heavier coils. In addition to wooden crates and steel frames, steel coils can also be packaged using steel containers or shipping containers. These containers are specially designed to transport heavy or bulky items and provide a secure and protective environment for the coils. The coils are loaded into the container and secured with steel bands or straps to prevent movement during transit. Regardless of the packaging method used, it is important to ensure that the steel coils are properly protected from moisture, corrosion, and other potential hazards. This may involve the use of moisture-resistant materials such as plastic or wax paper, as well as the application of protective coatings or wraps. Overall, the common methods of packaging steel coils for international shipping include wooden crates, steel frames or skids, and steel containers. These methods are chosen based on the size, weight, and specific requirements of the coils, and aim to provide maximum protection and security during transit.

- Q: Can steel coils be coated with anti-fingerprint materials?

- Yes, steel coils can be coated with anti-fingerprint materials. These coatings are designed to reduce the visibility of fingerprints and smudges, making the steel coils more resistant to marks and easier to clean.

- Q: What is the type of stainless steel used in knifes.

- There okorder / Stainless steel doesn't make the best knife blade. It doesn't sharpen as sharp or hold its edge as well. High carbon steel is better, but it rusts and discolors very easily so it's not as popular. A new thing (actually not new but popular these days) is to use a 'sandwich' of high carbon steel between two layers of stainless. So the actual edge is high carbon steel but the blade looks like stainless. I have some kitchen knives made this way (kind of expensive) and I love them. This same technique was used in Japanese katanas, swords used by samurai warriors.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- carbon will rust.. stainless doesn't rust unless it touches carbon so its definitely not stainless. Since its only 1.7% its extremely unlikely that it will rust unless you leave it outside for extreme long periods of time. Either way you should take care of it. Put it in the garage or something but you don't have to dry it after every use.

- Q: What is the process of uncoiling steel coils?

- The process of uncoiling steel coils involves using a machine known as a decoiler or uncoiler, which holds the coil and gradually unwinds it. The coil is typically mounted onto the decoiler's mandrel, and then the machine's motor or hydraulic system rotates the mandrel to release the tension on the coil. As the coil unwinds, it passes through a straightening mechanism, which helps to remove any residual coil set or curvature. The uncoiled steel is then ready for further processing or use in various applications.

- Q: What are the end uses of galvanized steel coil? What is the market like for this raw material? Would something like this be expensive?Also can you explain: PPGI.And the following specifications; what do they mean/represent?Required Composition :Thickness- 0.23mmCarbon- Max. 0.01%Manganese- Max. 0.20%Phosphorous- Max. 0.05%Sulphur- Max. 0.01%Silicon- ABT. 2.80 - 3.50%CRGO Quality- Prime QualityThanks

- Steel coil is the name given to thinner sheet steel when it is manufactured - it comes out of the machine and is formed into a coil for ease of handling storage and transportation. Thin sheet steel is used for plenty of stuff. It can be slit (cut) into thin strips as well as just cropped and used at one of the standard lengths x widths it leaves the mill. There is a big market for this material. It is used in many construction and engineering applications for things like ducting, boxes, gutters, down pipes, flashings, panels, car bodies etc., anything made of thin steel Galvanising is a flash coating of zinc which improves it's corrosion resitance. Cost wise it is a relatively cheap material. The chemical composition of steel varies, it is mostly iron but has various other elements added or present as impurities that change it's characteristics, depending on the end use. These additional elements can be selected to give better weld ability, hardness, tensile strength, corrosion resistance, flexibility and so on. In many applications excess of these chemicals is undesirable. For example sulphur and carbon are generally better at lower levels. The chemical composition data is contained in a material data sheet and expressed as a percentage of the chemical present and which gives the composition of a particular batch of steel, allowing it to be selected for particular applications and traced for quality assurance purposes. The list you have there shows presence and quantity of other elements in a particular batch of coil. The thickness is 0.23mm, quite thin.

- Q: What are the common methods of testing the strength of steel coils?

- Steel coils can be tested for strength using various methods. Tensile testing is one such method, which involves applying tension to the coil until it breaks. This test provides information about the coil's ability to withstand force and its tensile strength. It also reveals details about its yield strength and elongation properties. Another common method is hardness testing, which determines the steel's resistance to indentation or scratching. Different techniques like Rockwell, Brinell, or Vickers tests are utilized to measure hardness. This test helps determine the steel's ability to resist wear or deformation. To evaluate the coil's ductility and flexibility, bend testing is performed. The coil is bent to a specific angle and checked for any signs of cracking or fracturing. Bend testing assesses the material's capacity to withstand bending or forming procedures without failure. Additional methods of testing include impact testing, where controlled impacts are applied to assess the coil's resistance to sudden loading conditions, and fatigue testing, which involves subjecting the coil to cyclic loading to determine its endurance limit and potential for failure under repeated stress. It is important to note that the specific testing methods used may vary depending on the intended application and industry standards. Non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can also be employed to detect internal defects or flaws in steel coils without causing any damage.

- Q: I need to know the density of steel as one of my physical properties of steel. Any answers? If u have more physical or chemical properties of steel, that would help to thanks.

- This Site Might Help You. RE: What is the density of steel? I need to know the density of steel as one of my physical properties of steel. Any answers? If u have more physical or chemical properties of steel, that would help to thanks.

- Q: How do steel coils contribute to sound insulation in buildings?

- Steel coils can contribute to sound insulation in buildings by absorbing and reducing sound vibrations. The coils act as barriers, preventing the transmission of sound waves and minimizing noise transfer between different areas of a building.

- Q: What is the role of steel coils in the electrical industry?

- The electrical industry greatly relies on steel coils due to their versatile applications and significant contributions. Transformers, which play a crucial role in power distribution and voltage regulation, utilize steel coils as essential components. These coils facilitate the transfer of electrical energy between circuits, enabling efficient transmission over long distances. Moreover, electric motors and generators heavily rely on steel coils. These coils are wound around the stator and rotor, creating magnetic fields that facilitate the conversion of electrical energy into mechanical energy and vice versa. This conversion process holds immense importance in industries such as automotive, manufacturing, and renewable energy. Steel coils also serve a vital purpose in the production of electrical cables and wiring. They provide strength, durability, and protection to the conductive copper or aluminum wires within the cables, ensuring their structural integrity. This, in turn, guarantees safe and efficient electricity transmission. Additionally, steel coils find application in electrical equipment like solenoids and relays. Their presence enables the creation of magnetic fields that control the flow of electrical current. Furthermore, various electrical appliances, including refrigerators, air conditioners, and televisions, rely on steel coils as crucial components for their proper functioning. In conclusion, the role of steel coils in the electrical industry cannot be overstated. From transformers to motors, generators, cables, and electrical equipment, these coils contribute significantly to the efficient distribution, conversion, and transmission of electrical energy.

Send your message to us

Hot Dip Galvanized Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords