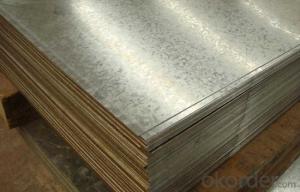

Hot-Dip galvanized/ aluzinc steel SGCC DX51D

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Applications:

Galvalume Coil widely used for roofing products, It is also the ideal base material for Prepainted Steel Coil.

1. roofing

2. gutters

3. unexposed automotive parts

4. appliances

5. furniture

6. outdoor cabinetry

Images:

- Q: What are the common methods of preserving steel coils?

- Some common methods of preserving steel coils include applying protective coatings, such as oil or paint, to prevent corrosion and rust formation. Another method is using VCI (Vapor Corrosion Inhibitor) paper or film, which releases chemicals that prevent oxidation. Additionally, steel coils can be stored in climate-controlled environments or wrapped in moisture-resistant materials to minimize exposure to moisture and humidity, which can accelerate corrosion.

- Q: is stainless steel a good steel for sensitive skin? or does it have to be surgical or sterling silver?

- When I worked at Spencer's the jewelry would usually said what grade/type of metal it was. As long as it says 316L surgical steel you should be ok. But like another person said, go to a professional piercer and buy jewelry there because you know that you're getting good quality. You get what you pay for!

- Q: Please give me the name of the steel, and the percentage of materials from what It consists, if you can give me five types of steel it will be better so I can decide. Thanks.

- This okorder /

- Q: What are the different types of surface finishes for steel coils?

- Steel coils can be finished in various ways, each with its own unique properties and advantages. Here are some of the most common surface finishes for steel coils: 1. Hot Rolled: Achieved by heating the steel and rolling it, this basic finish results in a rough and scale-like appearance with varying levels of imperfections. 2. Cold Rolled: This finish is obtained by subjecting hot rolled steel coils to a series of cold rolling operations. It yields a smoother and more uniform surface with improved dimensional accuracy and surface quality. 3. Galvanized: In this process, a protective layer of zinc is applied to the steel coil's surface, offering excellent corrosion resistance. It is ideal for outdoor applications and environments exposed to moisture and corrosive elements. 4. Stainless Steel: Stainless steel coils have a distinctive finish due to the presence of chromium, which forms a thin, invisible oxide layer. This finish provides exceptional corrosion resistance and an appealing appearance. 5. Electrolytically Zinc Coated: Also known as electrogalvanized, this finish involves applying a thin layer of zinc to the steel coil through electroplating. It offers good corrosion resistance and is commonly used in applications that prioritize aesthetics. 6. Pre-painted: Pre-painted steel coils have a surface finish coated with paint or other protective coatings. This finish provides corrosion resistance and aesthetic appeal, allowing for a wide range of colors and finishes. 7. Aluminized: Aluminized steel coils are coated with an aluminum-silicon alloy, providing excellent heat resistance. They are commonly used in high-temperature applications like exhaust systems or ovens. Ultimately, the choice of surface finish for steel coils depends on specific requirements such as corrosion resistance, aesthetics, durability, and heat resistance.

- Q: engineering sloutions related to steel fabrication

- The American Institute of Steel Construction develops codes for steel building design in the U.S. See the link to below to the Steel Solutions Center at their website. You can find free programs for designing structural steel elements from clicking on technical resources at that link. Most of the programs presume that you are a structural/civil engineer with knowledge of the steel design specifications.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless Steel does not rust...that is why it is used in our kitchens and the top kitchens of the world...!! sorry...Stainless Steel does not Tarnish either!

- Q: What are the different types of steel coil edges?

- There are several different types of steel coil edges, each with its own unique characteristics and applications. 1. Mill Edge: This is the most common type of steel coil edge. It is produced by cutting the coil at the mill and does not undergo any additional processing or treatment. Mill edge coils have a natural, slightly rounded edge, which makes them suitable for a wide range of applications. 2. Slit Edge: Slit edge coils are created by cutting the coil along its width using a slitting machine. This process results in a straight and smooth edge, making them ideal for applications that require precise measurements, such as automotive parts or electrical components. 3. Deburred Edge: Deburred edge coils have undergone an additional process to remove any burrs or sharp edges that may be present after slitting. This makes them safer to handle and reduces the risk of damage during fabrication or installation. Deburred edge coils are commonly used in the construction industry, especially for structural steel components. 4. Rounded Edge: As the name suggests, rounded edge coils have a rounded edge profile. This type of edge is achieved through a specific rolling process that creates a smooth and curved edge. Rounded edge coils are often used in applications where safety is a concern, such as in the manufacturing of household appliances or kitchen equipment. 5. Sheared Edge: Sheared edge coils are produced by cutting the coil with shearing blades, resulting in a straight edge with a slight burr. While sheared edge coils may have a rougher finish compared to other types of edges, they are still commonly used in applications that do not require a high level of precision, such as general fabrication or shelving. Overall, the choice of steel coil edge depends on the specific requirements of the application, including factors such as measurement precision, safety considerations, and aesthetic preferences.

- Q: What are the best types of steel for swords

- Don't know too much but I know combat grade katanas are made out of folded carbon-steel. Could also look into industrial steel grading systems if you are looking for something to show off at a martial arts tournament or something.

- Q: How are steel coils used in the manufacturing of railway equipment?

- Steel coils are a crucial component in the manufacturing of railway equipment due to their strength, durability, and versatility. These coils are typically made from high-quality steel and are extensively used in various applications throughout the railway industry. One primary use of steel coils in the manufacturing of railway equipment is in the production of train tracks. Steel coils are rolled out and shaped into long, continuous rails that form the foundation of railway tracks. The strength and durability of these coils enable the tracks to withstand heavy loads, constant train traffic, and harsh weather conditions. Additionally, the uniformity and consistency of steel coils ensure smooth and safe train operations. Furthermore, steel coils are also used in the manufacturing of railway wagons and carriages. These coils are formed and shaped into various components such as the framework, body panels, and structural supports of the wagons. The robustness of steel coils ensures the structural integrity of the wagons, enabling them to carry heavy cargo and withstand the rigors of railway transportation. Moreover, steel coils are utilized in the fabrication of various railway equipment accessories, including couplings, brake systems, and suspension components. These coils are transformed into precise shapes and sizes to meet the specific requirements of each accessory. The strength and resilience of steel coils make them ideal for these critical parts, ensuring efficient and safe operation of the railway equipment. In summary, steel coils play a vital role in the manufacturing of railway equipment. Their strength, durability, and versatility make them an essential material for the construction of train tracks, wagons, carriages, and various accessories. The use of steel coils ensures the safety, reliability, and longevity of railway equipment, making them an integral part of the railway industry.

- Q: How are steel coils used in the production of solar panels?

- Steel coils are not directly used in the production of solar panels. However, steel is typically used in the manufacturing of the structural frames and mounting systems for solar panels. These frames and mounting systems provide support and stability to the solar panels, ensuring their proper installation and long-term durability.

Send your message to us

Hot-Dip galvanized/ aluzinc steel SGCC DX51D

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords