Hot-Dip Aluzinc Steel Coil Used for Industry with So High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Coil Used for Industry

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

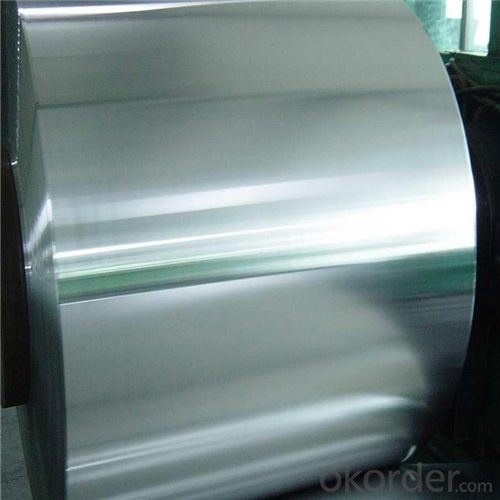

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

3.How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: what do you think about it? Is it a good steel for the money? the knife that i have with that steel is the kershaw chill. good knife for the price

- 8Cr13MoV is a decent blade steel...not a great steel, but about as good as you will generally find without paying much higher prices. It's used by a number of well known knife makers... It's basically equivalent to AUS-8 and will work and hold an edge reasonably well for most basic cutting chores. *************************************** From Wikipedia, the free encyclopedia: 8Cr13MoV, a Chinese stainless steel tempered at the Rc56 to Rc58 range and used in the Tenacious, Persistence, Ambitious, Resilience, Grasshopper, Kiwi3 and Byrd lines of knives. Often compared to AUS-8, but with slightly more Carbon.

- Q: i need some ideas of what material could replace iron or steel to make fridges, stoves, dishwashers, tractors, aircrafts, cars and buses and anything else that is made of iron and steel. anything is greatly appreciated as at the moment i have no idea what to put down.

- Material selection is a complex area. Iron and steel are very good materials in terms of their strength, stiffness and hardness (especially when compared to their density to give specific strength/stiffness. They are also relatively cheap and the economics of material selection is often the over-riding criteria. Each individual substitution has to be considered on the merits of what the component has to do and the environment in which it operates and often to replace steel with, say, aluminium, might not be appropriate or might require a redesign of the component to accomodate the lower strength and stiffness. Take one of your examples of a dishwasher; To replace the (cheap and thin) steel outer casing with aluminium would require thicker sheet to achieve the same stiffness. To replace the stainless steel inner you would need a corrosion resistant material (which rules out aluminium) which can be easily fabricated to shape. Nickel alloys would be harder to process and very expensive, but you might be able to use a bronze alloy. If you have time look in the library for a book on materials selection by Ashby - one of the best texts on the subject.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It needs to be RED hot, the hotter the better. Yes you can use a camp fire if you put the file directly in the hottest part of the coals, but it'll take about 5-10 minutes to heat. Charcoal briquettes would probably work better as a heat source. You can use something like a blow dryer to intensify the coals, that might help. You'll also need a bench vice, and the biggest pair of pliers you can find, for leverage. Bending steel's not easy even when it's hot. You could also use a bit of steel pipe that'll fit over the end of the file. Stick the file in the vise when red-hot, slip the pipe over the free end, and use the pipe to bend it. OR, you could use the old-fashioned method of just holding it with pliers in one hand, and hitting it with a 5lb sledge hammer with the other. use something solid as an anvil, like a large steel pipe. you mighe be able to get away with using a small log, but you'll have to work twice as hard. Safety glasses are MANDITORY for this type of thing. Do not attempt without eye protection at all times. Ear plugs are also a very good idea.

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- Some buildings are built on giant springs so they wobble when there's an earthquake but don't try to ride it out.

- Q: How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they serve as the core component of transformers and inductors. They provide a magnetic field necessary for the efficient functioning and transformation of electrical energy.

- Q: Galvanized Steel or Standard Steel. This will be for the grilling surface.

- Bare steel. Galvanized or ANY coated racks will produce deadly chemicals in the food when heated. Galvanizing is a tin coating applied to the surface of the iron. Cadmium is a deadly chemical when ingested and is one of the chemicals on refrigerator racks. I'm not sure about Stainless Steel. The safest way is if in doubt DON'T.

- Q: hey... i don't need to change my strings, but i found a set of Bronze acoustic guitar strings by pure tone... i have a few questions on them:can i put them on a steel string guitar? i know i can't put nylon strings on... but i don't see why i can't put bronzethey are light gauze... i have no idea what my current gauze is, but i play in Dropped D tuning... so would the E/D string (6th) be too loose? finally, can you get strings designed to be played in Drop D?any help is apprechiated :D

- Are you talking about a steel guitar or a steel string guitar. Bronze strings won't work properly on a steel/lap steel/electric guitar but hey are designed to be played on an acoustic or acoustic electric steel string guitar. Light gauge strings are OK. However, the low E may be too thin if you tune that down to D. Another thing to consider is that the neck truss rod probably needs to be adjusted slightly if you change string gauge. This procedure is fast and simple if you know what you're doing. You should however leave it to someone else if you don't know how it's done. If you play all the time in drop D, I would probably use a set of medium strings or have a light set and use a heavier low E-string. Personally, I use drop D on my acoustics from time to time. I use light strings and find this to work well for me.

- Q: Why can't the coil weight be too low?

- Because the steel coil is stored in warehouse stacking level, if the coil weight is too low, resulting in a single coil capacity is reduced, so that the steel roll easily crushed and deformed;

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q: What are the common transportation defects in steel coils?

- Steel coils can experience various transportation defects. Improper handling or securing during transportation is a major cause of coil damage, resulting in dents, scratches, or tears in the steel. Coil edge damage is another issue that arises when the coils lack proper protection or rub against each other during transit, leading to deformation or breakage of the edges. Additionally, coil shifting occurs when the coils are inadequately secured or braced, causing them to move and shift during transportation, potentially causing misalignment or damage. Moreover, coil corrosion is a prevalent defect that arises when the coils are exposed to moisture or corrosive elements during transportation, leading to rust and deterioration of the steel. To prevent these common transportation defects in steel coils, it is essential to implement appropriate handling, securing, and protection measures.

Send your message to us

Hot-Dip Aluzinc Steel Coil Used for Industry with So High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords