Hot-Dip Aluzinc Steel Coil Used for Industry with Our So High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Coil Used for Industry

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

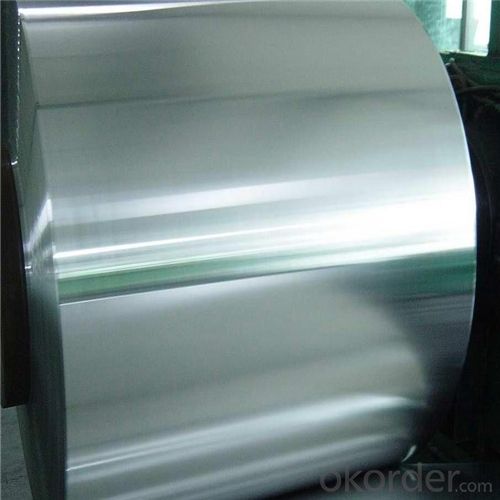

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the safety precautions while handling steel coils?

- To prevent accidents and injuries when dealing with steel coils, it is crucial to adhere to specific safety measures. Consider the following key precautions: 1. Personal Protective Equipment (PPE): It is essential to wear suitable PPE, including steel-toed boots, safety glasses, gloves, and a hard hat. This protective gear will safeguard against potential hazards like falling objects, sharp edges, and flying debris. 2. Training and Proper Lifting Techniques: Ensure that workers handling steel coils have received thorough training in safe lifting techniques. This involves lifting with the legs, maintaining a straight back, and avoiding twisting motions. By utilizing proper lifting techniques, the risk of back strains and injuries can be minimized. 3. Secure Storage and Stacking: When storing or stacking steel coils, ensure they are placed on a stable and level surface. Employ appropriate storage equipment like racks or pallets to prevent coils from shifting or falling. Stack the coils securely to prevent toppling or collapsing. 4. Inspection and Maintenance: Regularly inspect steel coils for any defects, such as sharp edges, loose bands, or damaged packaging. Avoid handling coils that appear damaged or unstable. Conduct regular maintenance on equipment like forklifts or cranes used for moving the coils to ensure safe operation. 5. Communication and Signaling: Implement clear communication and signaling protocols among workers involved in handling steel coils. This can involve hand signals or radio communication to coordinate movements and prevent accidents, especially in areas with limited visibility. 6. Load Limits and Capacity: Be aware of the load limits and capacity of the equipment used to move steel coils, such as forklifts or cranes. Overloading equipment can lead to instability, tipping, or collapse, thereby increasing the risk of accidents and injuries. 7. Proper Lashing and Securing: When transporting steel coils, employ appropriate lashing and securing methods to prevent movement or falling during transportation. This may entail using straps, chains, or other restraints to keep the coils securely in place. 8. Emergency Preparedness: Establish an emergency plan in case of accidents or injuries. Ensure that workers are trained in first aid and that emergency response equipment, such as fire extinguishers and first aid kits, are easily accessible. By adhering to these safety precautions, the likelihood of accidents and injuries when handling steel coils can be significantly reduced, creating a safer work environment for all individuals involved.

- Q: How do steel coils contribute to the HVAC ductwork industry?

- The HVAC ductwork industry relies heavily on steel coils as they are essential for creating ducts. These coils, typically made from galvanized steel, offer numerous advantages in this industry. First and foremost, steel coils are known for their durability and longevity, making them perfect for constructing HVAC ductwork. They can withstand high temperatures, pressure, and exposure to various environmental elements. This durability ensures that the ducts made from steel coils can effectively transport air for long periods without deteriorating or compromising their structural integrity. Moreover, steel coils are highly flexible and can be easily manipulated during the fabrication process. HVAC ductwork often requires customization to fit specific building layouts and designs. Steel coils can be effortlessly cut, bent, and shaped without sacrificing their strength. This flexibility allows for the production of ducts in different sizes, shapes, and configurations to meet the unique requirements of various HVAC systems. Additionally, steel coils provide excellent resistance to corrosion and fire. The galvanized coating on the steel surface acts as a protective layer, preventing rust and corrosion caused by moisture or chemical reactions. This corrosion resistance ensures that the ductwork remains functional and safe for an extended period. Furthermore, steel coils contribute to energy efficiency in the HVAC ductwork industry. The smooth surface of steel coils reduces air friction and turbulence within the ducts, resulting in smoother airflow and reduced energy loss. This improved energy efficiency leads to cost savings for building owners and occupants, as it reduces the amount of energy required to maintain a comfortable indoor environment. Finally, steel coils are readily available and cost-effective, making them a popular choice for HVAC ductwork fabrication. The market offers a wide supply of steel coils, ensuring efficient production and installation of ductwork systems. Additionally, their cost-effectiveness makes them an economical option for both small and large-scale HVAC projects. In conclusion, steel coils play a crucial role in the HVAC ductwork industry by providing a durable, flexible, corrosion-resistant, energy-efficient, and cost-effective material for duct fabrication. These unique properties ensure the construction of high-quality ductwork systems that effectively distribute air in buildings, promoting optimal comfort and functionality.

- Q: How are steel coils used in the manufacturing of body reinforcements?

- Steel coils are used in the manufacturing of body reinforcements by being shaped and welded to form sturdy structural components, such as pillars, beams, and frames, that provide strength and rigidity to the vehicle's body structure.

- Q: How are steel coils handled during loading and unloading?

- Steel coils are typically handled using cranes or forklifts during loading and unloading processes. They are carefully lifted and secured onto trucks or ships using special lifting attachments, and then securely fastened to prevent any movement or damage during transportation. When being unloaded, the coils are carefully lifted and placed onto a designated storage area or directly onto the production line, ensuring proper safety measures are followed to prevent accidents and maintain the integrity of the coils.

- Q: What are the different methods of painting steel coils?

- There are several methods of painting steel coils, including coil coating, spray painting, and powder coating. Coil coating involves applying a liquid coating to the surface of the steel coil, which is then cured and dried. Spray painting involves using a spray gun to apply paint to the coil, typically in multiple layers. Powder coating involves electrostatically applying a dry powder to the coil, which is then cured and fused onto the surface. Each method has its advantages and is chosen based on factors such as durability, cost, and desired finish.

- Q: What are the safety regulations for handling steel coils?

- The safety regulations for handling steel coils typically include wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots. Additionally, workers are often required to receive proper training on safe lifting techniques and use of equipment, as well as understanding the weight and dimensions of the coils being handled. It is important to ensure a clear and organized work area, secure stacking and storage practices, and the use of appropriate lifting equipment, such as cranes or forklifts, to minimize the risk of accidents, injuries, and damage to the coils or surrounding infrastructure.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed to improve their properties through a process called annealing, which involves heating the coils to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses, enhance ductility and toughness, and refine the grain structure of the steel, resulting in improved mechanical properties such as increased strength and reduced brittleness.

- Q: How are defects in steel coils detected and resolved?

- Defects in steel coils are detected through various methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Once a defect is identified, it is resolved through processes like grinding, welding, or cutting out the affected area. In some cases, the entire coil may need to be rejected or sent for further processing to eliminate the defect.

- Q: How are steel coils used in the manufacturing of renewable energy equipment?

- Steel coils are used in the manufacturing of renewable energy equipment to form the structural components, such as frames and supports, as well as to create the outer casing and housing for various renewable energy devices, including wind turbines, solar panels, and hydropower systems. The strength and durability of steel coils make them essential for ensuring the stability and longevity of these equipment, enabling them to withstand harsh weather conditions and operate efficiently for years.

Send your message to us

Hot-Dip Aluzinc Steel Coil Used for Industry with Our So High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords