HONGRI -stainless steel sheet 304/316/321/309S/310S/904L/202/201

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel plate/sheet detailed information:

Type | Wuxi boro-304/304L/316/316L/321/309S/310S/904L/202/201/430 stainless steel sheet |

Thinckness | 0.3mm-60mm |

Widthness | 50mm~2000mm or customized |

Length | 1000mm~8000mm or customized |

Brand name | FO SHAN HONG RI |

Standard | JIS, AISI, ASTM, GB, DIN, EN |

Material | 201/201/304/304L/316/316L/321/309S/310S/904L stainless steel sheet |

Surface | 2B,BA,HL,BK,NO.1,NO.4,8K,SB,etc |

Certificate | We accept the third inspections--SGS-BV etc. |

Application | Bridge, Shipbuilding,roofing,Car, etc |

Standard sheet sizes | 1000mm*2000mm,1250mm*2500mm,1219mm*2438mm,1500mm*3000mm We can produce other standard as customized |

Certification | BV,SGS ,CE |

Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

stainless steel plate/sheet detailed apllication:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

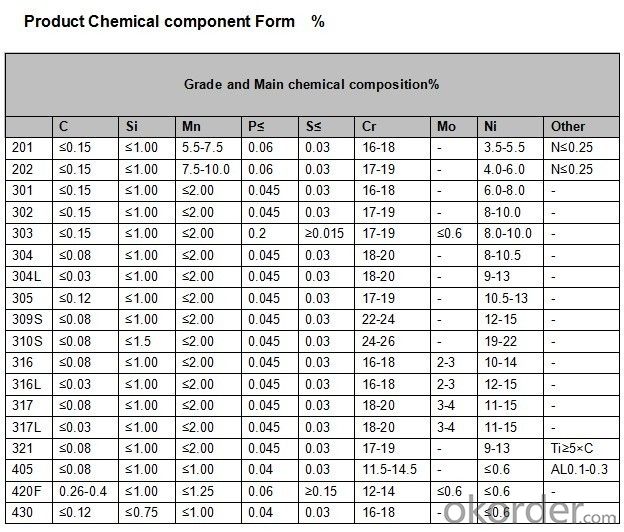

Chemical Composition:stainless steel sheet

Processing:stainless steel sheet

There are high-tech equipments to processing stainless coils and sheets/plates with skilled workers.

Cut to length

Decoiling and slitting

Grinding and brushing

Film protection

Plasma and water jet cutting

Folding and embossing

- Q: Can stainless steel strips be used in the aerospace fasteners?

- Yes, stainless steel strips can be used in aerospace fasteners. Stainless steel is known for its corrosion resistance, strength, and durability, making it a suitable material for aerospace applications that require secure and reliable fastening.

- Q: Are stainless steel strips suitable for brewery fermentation vessels?

- Yes, stainless steel strips are suitable for brewery fermentation vessels. Stainless steel is a popular choice for brewery equipment due to its durability, corrosion resistance, and ease of cleaning. It provides a hygienic and inert surface, which prevents contamination and ensures the purity of the beer during fermentation. Stainless steel strips offer strength and flexibility, making them suitable for constructing and reinforcing fermentation vessels in breweries.

- Q: Can stainless steel strips be powder coated?

- Yes, stainless steel strips can be powder coated. Powder coating is a versatile and durable finishing process that can be applied to stainless steel surfaces to enhance their appearance and provide added protection against corrosion and wear.

- Q: What are the maximum operating temperatures for stainless steel strips?

- The maximum operating temperatures for stainless steel strips differ based on the grade of stainless steel in use. In most cases, stainless steel strips can handle temperatures ranging from 1500°F to 1600°F (815°C to 870°C). It is crucial to consider that temperature limits can vary due to factors like alloy composition, surface finish, and intended application. Thus, it is advisable to refer to the manufacturer's specifications or seek expert advice to ascertain the precise maximum operating temperature for a particular grade of stainless steel strips.

- Q: Can stainless steel strips be used in railway applications?

- Stainless steel strips are indeed applicable for use in railway applications. Renowned for their resistance to corrosion and exceptional durability, stainless steel proves to be a fitting material for railway components that endure harsh weather conditions and heavy loads. Various railway applications, including track fastening systems, rail joints, signaling equipment, and electrical connections, can benefit from the utilization of stainless steel strips. Incorporating stainless steel strips in railway applications significantly contributes to the longevity and dependability of the railway infrastructure.

- Q: What are the factors affecting the creep resistance of 111 stainless steel strips?

- The factors affecting the creep resistance of 111 stainless steel strips can be numerous and include: 1. Composition: The chemical composition of the stainless steel strips, including the presence of alloying elements such as chromium, nickel, and molybdenum, can significantly impact its creep resistance. Higher levels of these elements generally improve resistance to creep deformation. 2. Microstructure: The microstructure of the stainless steel strips, including the size, distribution, and stability of the various phases and grain boundaries, can influence creep resistance. A fine and uniform grain structure with minimal grain boundary sliding is desirable for improved creep resistance. 3. Temperature: Creep resistance decreases as temperature increases. Higher temperatures promote the diffusion of atoms, resulting in increased creep deformation. Therefore, stainless steel strips intended for high-temperature applications should be designed to withstand the specific temperature range without significant creep deformation. 4. Stress level: The applied stress or load on the stainless steel strips can affect creep resistance. Higher stress levels can accelerate creep deformation, leading to reduced creep resistance. It is important to consider the stress levels that the strips will be subjected to during their intended service life. 5. Time: Creep resistance is time-dependent, meaning that the longer the stainless steel strips are subjected to a constant load or stress, the more susceptible they are to creep deformation. Therefore, the duration of the applied load or stress should be considered when assessing the creep resistance of 111 stainless steel strips. 6. Surface condition: The condition of the stainless steel strip's surface, including the presence of defects, scratches, or surface roughness, can influence its creep resistance. A smooth and defect-free surface can help minimize stress concentration and reduce the likelihood of localized creep deformation. 7. Environmental factors: The presence of aggressive environments, such as high-temperature gases or corrosive substances, can affect the creep resistance of stainless steel strips. Corrosion or oxidation can lead to the degradation of the material, reducing its creep resistance. 8. Heat treatment: The heat treatment process used during the manufacturing of stainless steel strips can significantly impact their microstructure and, consequently, their creep resistance. Proper heat treatment procedures, including annealing, quenching, and tempering, can optimize the material's creep resistance properties. It is important to note that these factors are interrelated and should be considered together when evaluating the creep resistance of 111 stainless steel strips.

- Q: What is the melting point of stainless steel strips?

- The melting point of stainless steel strips is subject to variation based on the specific alloy employed. Typically, the melting point of stainless steel strips falls within the range of 2,500 to 2,800 degrees Fahrenheit (1,370 to 1,540 degrees Celsius). Nevertheless, it should be emphasized that dissimilar grades or compositions of stainless steel might possess marginally diverse melting points.

- Q: Are stainless steel strips suitable for brewery tanks?

- Indeed, brewery tanks find stainless steel strips to be incredibly suitable. Given its outstanding corrosion resistance, durability, and hygienic qualities, stainless steel remains a favored option for brewery equipment. By utilizing stainless steel strips, the tanks are safeguarded against rust, staining, and chemical reactions, rendering them exceptionally well-suited for beer storage and fermentation. Moreover, stainless steel's ease of cleaning is paramount in preserving the beer's quality and flavor. Consequently, incorporating stainless steel strips in brewery tanks emerges as a dependable and pragmatic decision for the brewing industry.

- Q: How do stainless steel strips perform in high-pressure environments?

- Stainless steel strips are known for their exceptional performance in high-pressure environments. These strips are commonly used in industries such as oil and gas, chemical processing, and power generation, where they are exposed to extreme pressures and temperatures. One of the key advantages of stainless steel strips is their high strength and resistance to deformation. They can withstand the intense pressure exerted on them without distorting or losing their structural integrity. This makes them ideal for applications where there is a need for reliable and durable materials. Moreover, stainless steel strips have excellent corrosion resistance properties, especially when alloyed with elements such as chromium and nickel. This protects them from the harmful effects of high-pressure environments, which often involve exposure to corrosive substances, such as acids or salts. The resistance to corrosion ensures that the strips can maintain their performance and structural strength over time. Another important feature of stainless steel strips is their ability to withstand high temperatures. They have a high melting point and can handle extreme heat without deforming or weakening. This makes them suitable for applications where high temperatures are involved, such as in heat exchangers or boilers. Furthermore, stainless steel strips offer excellent fatigue resistance, which means they can withstand repeated cycles of pressure fluctuations without cracking or failing. This is crucial in high-pressure environments where the material is subjected to constant stress and strain. Overall, stainless steel strips are highly reliable and perform exceptionally well in high-pressure environments. Their strength, corrosion resistance, heat resistance, and fatigue resistance make them a preferred choice for various industries where reliability and performance are critical.

- Q: Are stainless steel strips resistant to crevice corrosion?

- Yes, stainless steel strips are generally resistant to crevice corrosion. Stainless steel is known for its high corrosion resistance, and this includes resistance to crevice corrosion. This type of corrosion occurs in confined spaces or crevices where oxygen levels are low, leading to localized corrosion. However, stainless steel's composition, particularly the presence of chromium, ensures that a protective oxide layer forms on the surface, preventing the initiation and propagation of crevice corrosion. Nonetheless, it is important to note that the resistance to crevice corrosion may vary depending on the specific grade of stainless steel used and the conditions in which it is exposed.

Send your message to us

HONGRI -stainless steel sheet 304/316/321/309S/310S/904L/202/201

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords