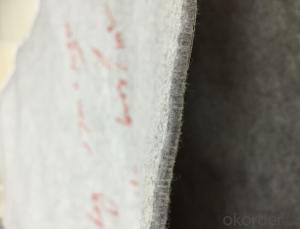

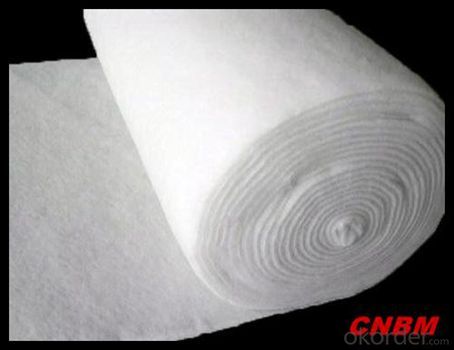

Rs580i Highist Nonwoven Geotextile Polyester & Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by differentequipment and technology to get different thickness. The main function is filtration, drainage, reinforcement. It has good impermeability and resistance to deformation

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: What is the role of permeability in geotextiles?

- The role of permeability in geotextiles is to allow the passage of water or other fluids while restraining the movement of soil particles. It helps in drainage and filtration processes, preventing the buildup of excess moisture and maintaining the stability and integrity of the surrounding soil or substrate.

- Q: What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects can vary depending on the specific project requirements. However, some common specifications include the desired tensile strength, puncture resistance, and permeability of the geotextile. Additionally, the required thickness, weight, and filtration efficiency may also be specified. It is important to consult the project specifications and consider factors such as soil type, groundwater conditions, and anticipated loads to determine the appropriate specifications for geotextiles in subsurface drainage projects.

- Q: What are geotextiles?

- Geotextiles are synthetic materials used in civil engineering and construction projects for their specific properties such as filtration, separation, reinforcement, and drainage. They are permeable fabrics that are designed to improve the performance and longevity of soil and other materials in various geotechnical applications.

- Q: Road Central isolation belt (5 m wide) Drainage No design Waterproof geotextile laying and gravel blind ditch, are design flaws?

- Should be it, the general design will have this. If you need to contact me, see the information

- Q: What are the advantages of using geotextiles in green building design?

- Geotextiles offer numerous advantages in green building design. Firstly, they provide effective erosion control by stabilizing soil, preventing sediment runoff, and reducing the need for traditional erosion control measures. Additionally, geotextiles enhance water filtration and drainage, promoting healthier soil and preventing waterlogging. These materials also aid in weed control, reducing the need for herbicides and minimizing maintenance efforts. Moreover, geotextiles can improve the structural integrity of green building projects by reinforcing soil and preventing subsidence. Lastly, they offer a sustainable solution as they are typically made from recycled materials and can be reused or recycled themselves.

- Q: What are the different geotextile installation techniques for steep slopes?

- There are several geotextile installation techniques that can be used for steep slopes. These include anchoring the geotextile with soil nails or rock bolts, using geotextile wraps or sleeves around soil or rock slopes, and installing geotextile mats or grids on the slope surface. These techniques help to stabilize the slope, prevent erosion, and improve overall slope stability.

- Q: What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, several factors need to be considered. These include the type and strength of geotextile to be used, the slope angle and height, soil properties, expected loads and stresses, water drainage and erosion control measures, construction methods, and long-term performance requirements. Additionally, site-specific conditions such as climate, vegetation, and nearby structures should also be taken into account. Proper consideration of these factors ensures a safe and stable design that effectively mitigates slope failures and erosion.

- Q: What are the different geotextile puncture resistance test methods?

- There are several geotextile puncture resistance test methods, including the Cone Drop Test (ASTM D1709), the CBR Puncture Test (ASTM D6241), the Ball Burst Test (ASTM D3787), and the Trapezoidal Tear Test (ASTM D4533). These tests assess the ability of geotextiles to withstand puncture forces and provide valuable information about their durability and performance in various applications.

- Q: Can geotextiles be used in the construction of stormwater ponds?

- Yes, geotextiles can be used in the construction of stormwater ponds. Geotextiles are often used as a lining material to reinforce the pond's base and slopes, providing stability and preventing erosion. Additionally, geotextiles can act as a filter, preventing fine particles from entering the pond and improving water quality.

Send your message to us

Rs580i Highist Nonwoven Geotextile Polyester & Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords