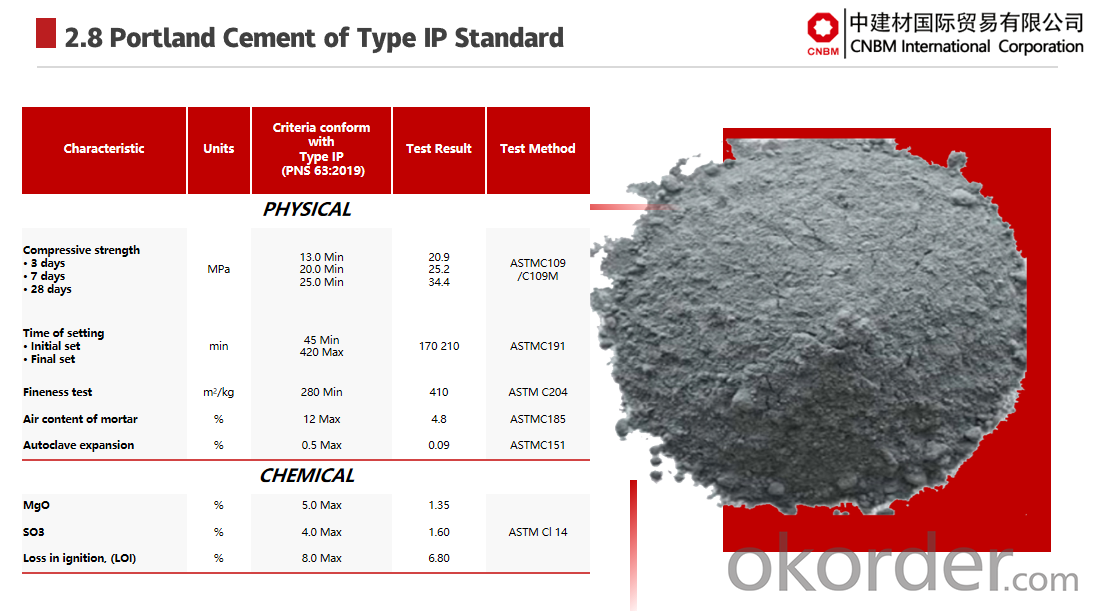

Highest quality for Portland Cement of Type IP Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: Please help!A couple of months ago i adopted a cat from the cats protection league. she is now starting to go out but she seems to always go up onto my cement bonded asbestos garage roof to go to the front of my house. When i call her back in, she goes on the roof to get back to my back door. Can she get asbestos fibers from the roof which is not broken on her paws.

- Undamaged asbestos that is bonded into cement tiles, typically pose as a low risk to public health, but still a risk. Evidence, using electron microscopes, show that asbestos cement products release fibres into the air under normal wear and tear conditions. A 1980 study showed that asbestos was found in the air within 20 inches of a 17-year-old weathered asbestos cement tile. It is 10Xs higher than 100 meters (328 feet or 33 yards) from the same wall. Blue and Brown asbestos are generally considered to be more deadly than White asbestos. Also, outdoor cats lives are shortened by 2/3% then an indoor cat and vet expenses are higher due to diseases, fights, accidents, poisons, stranger mistreatments, traps, etc. situations that the cats may get into. Good luck!

- Q: I cant figure out what consistency to mix this cement at. I am pouring it for a shower but need to know how much water to add. I would REALLY like an exact calculation, like 20 parts cement to 1 part water for example. Anybody know? Thank you! Again, this is for a shower......

- finally a mixture that wealthy will shrink and crack. it fairly is only too annoying and as a result too brittle for stucco - which correct could be approximately a similar density because of the fact the substrate (if brick) or rather mushy if on cord lath so as that it may amplify and settlement with temperature ameliorations and not crack. we've a house inbuilt 1890, and those days (18 months in the past) had approximately 4 hundred sq. ft of undesirable stucco got rid of and altered, approximately 100s.f. on mushy brick, the rest on new stainless-steel cord lath and beads. The brick application became 3:a million sand-to-portland cement, the 300s.f. final became 4:a million sand to Portland Cement. the two had admixtures extra in to the actual-coat (producer's colored mixture) for colour, solid adhesion and adaptability. the two have been actual 3-coat applications which blanketed soaking the bricks previous to installation so as that the stucco cured correct. so some distance, curiously great and shows no cracks, separation or splitting.

- Q: A 20 pound bag of Economy brand cement mix contains 25% cement and 75% sand. How much pure cement must be added to prduce a cement mix that is 40% cement?

- x+20(.25)=.40(x+20) x+5=.40x+8 Subtract .4x from both sides: .6x+5=8 Subtract 5 from both sides: .6x=3 Divide .6 from both sides: x=5 5 pounds of pure cement.

- Q: We have a balcony, and would like to turn in into a patio.The rain get on which is fine, but there are some parts of the balcony that is a little low, causing a puddle.We bought black roof cement to fill it up but at times it soft.What do I do to keep it hard and dry? Or am I buying the wrong product?

- wrong product the black cement sometimes called plastic is made to stay flexible to expand with the roof and not dry and crack. not sure how big of an erea but maybe some ice and water shield covering all of the balcony then a outdoor carpet on top of it . almost all asphalt roofing will become soft when it gets hot and walking on it when it is cold can crack it. ice water shield is very stick on one side and will seal its self around nails staples that you use to hold the carpet down. just a thought hope this helps

- Q: i have to get 2 yards of cement from a quot;shortloadquot; truck to the back patio area in 20 minutes is this possible. approx 80 feet away

- have some one help get 2 barrows going, a cubic yard is 3 foot square, so 4 loads in 20 min ? going to be hard or rent a cement buggy self powered, will haul a yard at one time

- Q: What is the most common cement used in concrete?

- Portland Cement is the most common cement used to make concrete.

- Q: What is Oilfield cement, is it the same as the cement that cars drive on?

- I have never worked in the Oil Patch, but I believe oilfield cement is a mixture of sand, aggregate and a barium compound (barium carbonate, maybe). If you look at the Periodic Table, you will see that barium lies under calcium, and has the same properties (more or less). Since barium is denser, when an over-pressured oil reservoir is breached, this mixture plugs up the drill hole until the well can be capped. This is a major use of the element barium.

- Q: I have decided to cement the outside of my house in a stucco design. What materials will I need?

- i recommend cement mix..the 'just add water' kind. My dad makes railings and when installs them on a sidewalk or concrete stairs, that what he uses. you can go to your local hardware store where they might have some. (home depot, sears, etc.)

- Q: Why do the bulk cement trailers or the silo trailers use a peculiar shape?

- Because the gravity is what makes the cement flow from the upper portion to the ground area

- Q: i would like to match the cement on my driveway. i have a small patchthat i need to fill in. the driveway is a very light gray. which cement would i use to match the shade.

- the odds are you will never match it-as concrete dries it changes shades

Send your message to us

Highest quality for Portland Cement of Type IP Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords