High Voltage Frequency Drive 13.8KV 2000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

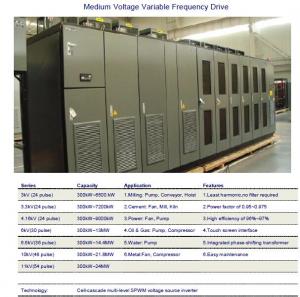

High Voltage Variable Frequency Drives are designed to be highly reliable with high-performance, yet easy to use.It can satisfy users' need for changing the speed of fans or pumps,as well as improve the productivity.

The series are compatible with all types of three-phase medium voltage asynchronous motors.

Specification and advantages :

1. Voltage resource VFD, direct input of 3,3.3,4.16,6,606 and 10 kV,direct output of3,4.16, 6,6.6 and10 kV,no output transformer necessary. High input power factor, low harmonic current, no power factor corrective capacities and harmonic filters required.

2. Sinusoidal multi-level PWM output waveform, no output filter required, can be directly connected to standard induction motor,no harm to the insulation of the cable or the motor, low harmonics of the motor, reduction of vibration of the shafts or the vanes,with the maximal length of the output cable of 1000m.

3. Friendly human-machine interface.

4. Modular design of the power circuits simplifies maintenance routine.

5.The medium voltage circuits are linked with the controller by the optical fibers,which keep the controller safe and away from the disturbance.

6. The complete fault monitor circuit, accurate fault alarm and protection.

7. Integrated cooling blower

8. The control logic can be conveniently changed with the help of the integrated PLC.

9. Offer both field control and remote control in monitor station, providing convenient controlling options.

10. Support most of the industrial standard protocols (Profibus, Modbus, TCP/IP, etc.)

11. Compatible with industrial standard signal of 0-10V/4-20mA

12. Able to operate at either open loop control or closed loop control status with the integrated PID regulator.

Spare Parts of MV VFD Storage and Replacing

Spare parts is one of important parts of Medium Voltage Variable Frequency Drive (MV VFD). After receiving the spare parts, please inspect it for damage immediately. If find any damage, please make report immediately. To ensure the spare part not to be damaged, please pay attention to the following content: The store location should without any impacting or vibration and also should prevent the damage caused by humidity, frost, temperature, grit. The spare parts shall be stored in dry ambient, which is far away from the corrosive gas. All printed circuit board should be stored in electrostatics proof package. Please handle the packaged spared parts carefully for the convenient of troubleshooting and maintenance after send back to factory.

Replacing Spare Parts from the original package, prevent carefully from electrostatics discharging. The impropriety operation may cause sensitive parts damage, and the following procedures should be followed .Even short-distance transportation, spare part should also be shipped in electrostatics proof package

When handling the PCB, always hold it by its edge to prevent terminals and component damage. The PCB audits component should place on a grounded operation table to prevent electrostatics effect .The failed PCB should also be shipped or delivered in electrostatics proof package to prevent the electrostatic damage. To learn more about power cell, www.okorder.com welcome you to login in.

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: Is the laptop power adapter high temperature normal? Is there anything else?

- Summer heat is normal, as long as it is not the kind of hand touch on the bubble temperature, no problem

- Q: 4 pole 380V 4-5.5KW frequency conversion motor and inverter about how much money, such as the use of electromagnetic speed motor comparison

- About 2,000 yuan, electromagnetic speed and vector inverter can bring feedback

- Q: Can the laptop's power adapter be used for years?

- Most laptop power adapters can be used for 100 ~ 240V AC (50 / 60Hz). Basically, most of the notebook computers are external power supply, with a power cord and the host connection, which can reduce the size and weight of the host, only a very small number of models built in the host power.

- Q: How does the laptop's power adapter open

- Notebook power adapter using the correct method] 1. Try to avoid the use of outdoor or harsh environments to prevent the adapter is exposed or damp. 2. When you are not using the adapter, please unplug the power plug. Because, for a long time the power will let the adapter has been in working condition, will affect the end of life. 3. Although the adapter is a broadband operating voltage, marked from 100V-240V can be, but if the voltage is extremely unstable in the case of use, the same will cause damage to the power adapter.

- Q: 2 pole 0.75 kW motor can increase the speed through the inverter?

- if the 4-pole motor to rise to 2-pole motor frequency, The frequency of the motor rises to about 100 Hz, which is easy to implement for the frequency converter.

- Q: Motor nameplate on the standard 2P, I set the number of motor pole in the inverter, is set 2 or 4 pole?

- 1,2P refers to the number of motor poles, so it is certainly even 2, if the inverter is set to determine the number of motor poles, please write 2P value, if 2P = 4, please write 4 3, look at the nameplate on the motor rated speed for how much, you can confirm the number of motor poles. (N = 60f / p) P: pole pairs

- Q: Laptop computer about electricity no electricity, is the power adapter problem?

- To judge this is very simple: 1. The computer is in the battery state to see if it works properly. If it does not work, the battery has a problem 2. Remove the battery from the computer with a power adapter to see if it is working properly. If not, there is a problem with the power adapter 3. If the two states can work that is the computer charge management part of the poor contact and other issues.

- Q: Can the HP laptop's power adapter be universal?

- If the power adapter socket is the same as the output voltage can be common. But there are a few places to note, HP notebook power adapter output voltage there are many, the most common 19V and 18.5V, but even if the output voltage is the same, the output current may be different, that is, the output power is not the same , If your notebook needs a larger input power, then you have to use the match can be, the lower power may not make the battery normal use, and even harmful to the battery.

- Q: What is the adapter?

- An adapter is a physical device that allows a hardware or electronic interface to interface with another hardware or electronic interface (adapt and without any loss).

- Q: Jd1a-40 motor speed controller and how to connect the motor

- Speed ??control motor wiring method: 3.4.5 is the terminal of the tachogenerator (U / V / W) from the right-to-left order of 1.2 for the excitation coil (F1 / F2) terminal, from the extended end of the speed motor (electromagnetic clutch) Master 7 plugs on the air plugs (governor): terminal 1.2 for the 220v input, 3.4 on the speed of the motor on the excitation coil, 5.6.7 speed motor on the tachogenerator. Motor speed control method: The speed regulating motor is to change the speed of the motor by using the series, voltage, current, frequency and so on of the motor to make the thyristor voltage regulation method the best.

Send your message to us

High Voltage Frequency Drive 13.8KV 2000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords