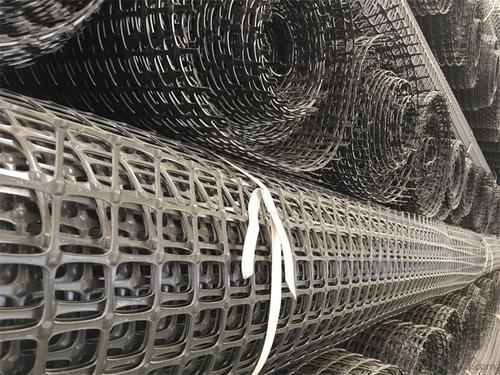

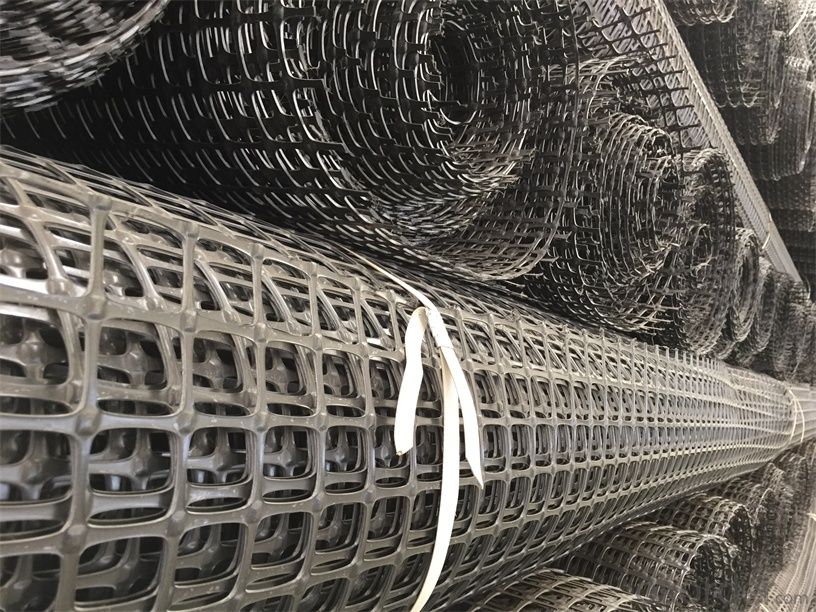

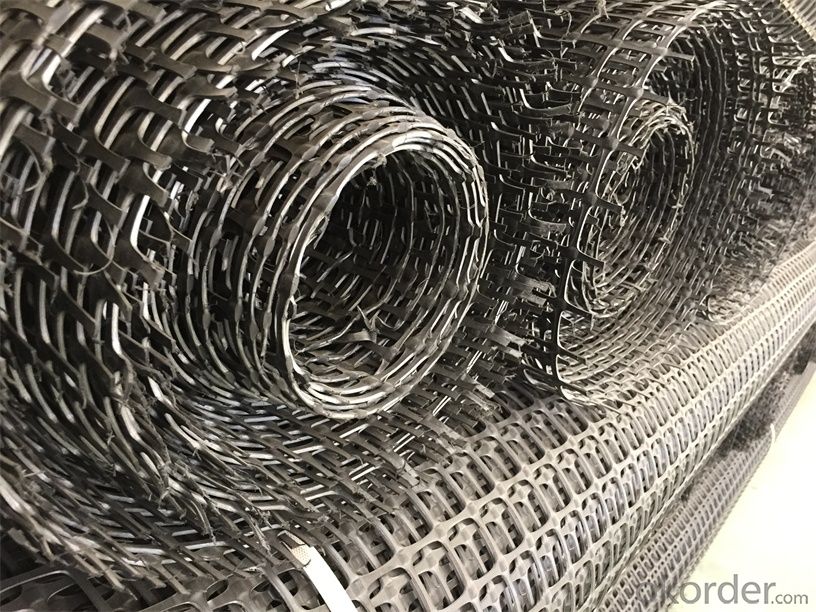

High Tensile Strength Black Uniaxial Geogrids for Roads

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

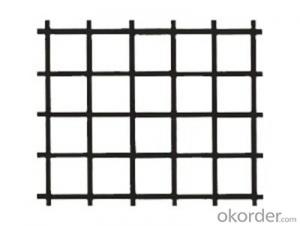

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: What is the meaning of two-way 50kN geogrid

- Ministry of industry standards

- Q: What are the design considerations for geogrid-reinforced structures?

- Some design considerations for geogrid-reinforced structures include the selection of appropriate geogrid materials, the determination of the required geogrid strength and stiffness, the analysis of soil-geogrid interaction, the assessment of long-term durability, and the consideration of construction and installation techniques. Additionally, factors such as site conditions, loading conditions, and environmental considerations should be taken into account during the design process.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can impact the installation and survivability of geogrids in harsh environments. Firstly, the quality and strength of the geogrid material itself play a significant role. Geogrids made from durable and high-quality materials are more likely to withstand harsh conditions. Secondly, the installation technique is crucial, as improper installation can lead to geogrids being damaged or dislodged. The type and condition of the subgrade also affect the geogrid's survivability, as a stable and well-prepared subgrade provides a solid foundation for the geogrids. Additionally, environmental factors such as extreme temperatures, moisture levels, and chemical exposure can impact the long-term performance and durability of geogrids in harsh environments.

- Q: How do geogrids help in reducing the use of natural resources?

- Geogrids help in reducing the use of natural resources by providing reinforcement and stabilization to soil structures. They allow for the use of less soil and aggregate materials in construction projects, reducing the need for excavation and mining of natural resources. Additionally, geogrids improve the durability and longevity of structures, reducing the need for frequent repairs or replacements, further conserving natural resources.

- Q: Can geogrids be used in shoreline erosion control?

- Yes, geogrids can be used in shoreline erosion control. Geogrids are commonly used in coastal engineering projects to stabilize the soil and prevent erosion by reinforcing the shoreline. They are effective in providing structural support and preventing the loss of sediment, thereby reducing erosion and protecting the coastline.

- Q: What materials are used to make geogrids?

- Geogrids are typically made from materials such as polyester, polyethylene, or polypropylene. These materials are chosen for their strength, durability, and resistance to environmental factors like UV radiation and chemical degradation.

- Q: The geogrid is not less than 3 meters on each side, what does it mean?

- At present, the largest width of single geogrid is 6 meters

- Q: What is the calculation method of geogrid?

- According to the above formula: thickness hypothesis 3mm5000*0.3/3.14 square is 21.8, multiplied by 2 is 43.6cm, with the amount of deviation out of the 2-3cm. In addition, plastic grille, steel and plastic grille are not rolled into solid, calculated out there will be some deviation.

- Q: Can geogrids be used in reinforcement of bridge approach embankments over soft soils?

- Yes, geogrids can be used in the reinforcement of bridge approach embankments over soft soils. Geogrids are commonly utilized in civil engineering projects to enhance the stability and load-bearing capacity of soil structures. In the case of bridge approach embankments, geogrids can be installed to improve the overall strength of the soil, reduce settlement, and prevent potential failure or deformation caused by the soft soil conditions.

- Q: What are the different types of geogrids?

- There are several types of geogrids, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids have strength in only one direction and are often used for soil reinforcement in walls and embankments. Biaxial geogrids offer strength in two perpendicular directions and are commonly used for stabilizing and reinforcing soil in applications such as road construction and retaining walls. Triaxial geogrids provide strength in all three directions, making them suitable for stabilization and reinforcement in areas with complex soil conditions or heavy loads.

Send your message to us

High Tensile Strength Black Uniaxial Geogrids for Roads

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords