High Alumina Brick - Firebrick/Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Jiangsu, China (Mainland) | Shape: | Brick | Material: | Mullite |

| SiO2 Content (%): | 0.3-15 | Al2O3 Content (%): | 48%-85% | MgO Content (%): | 0.8-1.2% |

| CaO Content (%): | 0.34% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0.1-0.3% |

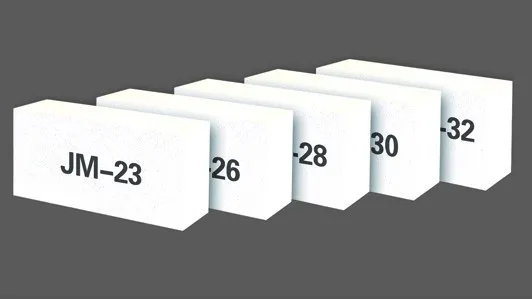

| SiC Content (%): | 1.2-1.4 | Model Number: | JM23 JM26 JM28 JM30 JM32 | Brand Name: | cnbm |

| Name: | insulating Brick | size: | 230*115*65mm | Weight: | 1.19-5kg |

| Color: | white and yellow | Raw material: | mullite & clay | Usage: | Fire resistance place |

| Certificate: | ISO9001 |

Packaging & Delivery

| Packaging Details: | Export wooden pallet or as customers requirements |

| Delivery Detail: | Shipped in 5 days after payment |

refractories insulating bricks mullite bricks

New type quality thermal insulating refractory. It contains alumina 50%-85%, and has mullite (3Al2O3.2SiO2) as major phases and binder phase. Working temperatures are from 1350° C to 1700° C.

Features:

1). High strength as containing high temperature structure

2). Low creep rate at high temperature

3). Low thermal expansion rate

4). Strong resisting chemical erosion performance.

5). Fine resisting thermal shock performance.

3. Property (See below table)

- Q: What is the difference between corundum and high alumina??

- The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- 1. The shell of the furnace is welded by section steel and steel plate. 2, the furnace cover support adopts steel and guide rail combination mobile type. 3. The heating element is made of high resistance alloy 0Cr25Al5 produced by Beijing Shougang Group and arranged on the furnace side. 4, because the bottom bearing adopts high aluminum bricks, the circle center of the furnace set small, inside and outside heating. 5 、 furnace cover adopts hydraulic lifting, motor control, automatic walking. 6 、 temperature control system adopts PID SCR control, high accuracy.

- Q: What are the alloy wear resistance materials?

- Alloy wear-resistant materials from different manufacturers different components in Beijing Naimo company as an example, the following alloy wear resistant material:1: Ni Cr alloy wear-resistant material2: chrome carbide wear-resistant material3: high manganese alloy wear-resistant material4: tungsten carbide alloy wear-resistant material5: nickel tungsten alloy wear-resistant material

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: The difference between ordinary and diatomite brick refractory brick

- Insulation products made from diatomaceous brick and porous diatomite. The main raw material is natural porous diatomite, and then a small amount of clay and fuel are added. The volume density of diatomite brick was 0.7g/cm3, compressive strength at room temperature is 1 ~ 2MPa, the coefficient of thermal conductivity at 400 C for 0.13 ~ 0.20W/ (M - K), the apparent porosity is greater than 70%, the coefficient of thermal expansion (1280 degrees) 0.9 x 10 - 6 DEG -1, refractoriness is greater than 1250 DEG C. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius.

- Q: How to distinguish the good or bad of the high aluminum brick?

- The general high alumina bricks used in the steel, steelmaking, hot blast furnace, electric furnace, blast furnace, reverberatory furnace, rotary kiln lining of industrial furnace in China, mainly composed of a bauxite; sillimanite minerals (including kyanite, andalusite, sillimanite etc.); synthetic material, such as alumina synthesis of mullite, corundum, etc.. High aluminum brick has good quality, high refractoriness, long life and other characteristics, is the main use of refractory brick kiln products, commonly used units can not distinguish the quality and grade of high aluminum brick right in the procurement time, caused by the high prices to buy low grade products, thereby reducing the furnace life therefore, Zhengzhou's Sindh yuan refractory material factory in here is simple to introduce how to identify the quality when purchasing brick high alumina brick.Color: in the purchase of high alumina brick, first of all to see the color, high quality aluminum brick surface smooth, yellow color white, four sides smooth, no broken angle, no cracksWeight: the weight of a block of bricks to be called, according to the standard weight level, high aluminum brick weight of 4.5 kg. Two grade high alumina brick weighs 4.2 kg, three high aluminum brick weighs 3.9 kg, the same level, the same parameters can reach this standard can be regarded as high-quality high aluminum bricks, the opposite is not up to the weight that the quality is good, if there is a crack, four angle uneven, off angle phenomenon, then substandard products, some of the above points to help to the purchaser

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Two times mullite refers to the content of aluminum is about 70%, in high temperature sintering, the expansion coefficient is large, the thermal expansion rate is high.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

Send your message to us

High Alumina Brick - Firebrick/Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords