High Swelling Bentonite Waterproof Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 300000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Bentonite Waterproof Blanket Description:

Bentonite composite waterproof blanket (GCL) is a new type of geosynthetic materials. It is mixed by a natural grading sodium base bentonite particles and corresponding admixture. And by the special technology and equipment, it is fixed between the two layers of geotextile bentonite particles, made from bentonite waterproof blanket.It not only has all the characteristics of geotechnical material, but also has excellent waterproof performance (permeability).

2.Main Features of Bentonite Waterproof Blanket:

•Excellent waterproof performance.

•Having all properties of geotextile material, such as separation, reinforcement and protection, filter, etc.

•Easy for construction

•No affected by the limitation of the environment temperature, even under 0 ℃ can be construction too.

•The cost performance is relatively high.

•Being used in very wide range.

3.Bentonite Waterproof Blanket Specification:

| Expansion coefficient | ≥24mL/2g | |||

Fluid loss ≥ 24mL/2g | ≤18mL | |||

Tensile strength

| ≥400N | |||

| Peel strength | ≥65N | |||

Permeability | ≤5*10-9cm/sec |

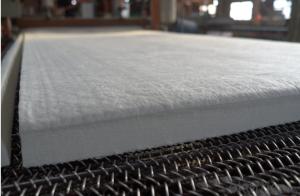

4.Bentonite Waterproof Blanket Images:

- Q: Can a waterproofing membrane be used in residential buildings?

- Yes, a waterproofing membrane can be used in residential buildings. It is commonly used in basements, bathrooms, and other areas prone to moisture to prevent water damage and leakage.

- Q: Can a waterproofing membrane be used for a planter roof?

- Indeed, the utilization of a waterproofing membrane is applicable to a planter roof. The primary purpose of a waterproofing membrane lies in its ability to impede water infiltration, thus rendering it highly suitable for safeguarding the roof of a planter. By doing so, it effectively shields the underlying structure from water-related harm, encompassing potential leakages and decay caused by moisture. Furthermore, the implementation of a waterproofing membrane also aids in preserving moisture within the planter, thereby guaranteeing that plants obtain sufficient hydration.

- Q: Can a waterproofing membrane be used in areas with high humidity and moisture?

- Yes, a waterproofing membrane can be used in areas with high humidity and moisture. In fact, it is specifically designed to prevent water infiltration and protect the underlying structure from damage caused by moisture. Waterproofing membranes are commonly used in areas such as basements, bathrooms, and kitchens, where the presence of moisture and humidity is more pronounced. These membranes create a barrier that prevents water from seeping through walls, floors, or roofs, and they are typically made of materials like rubber, asphalt, or PVC. By installing a waterproofing membrane, you can effectively manage moisture levels and protect your property from potential water damage, mold growth, and other related issues.

- Q: Are there any specific considerations for installing a waterproofing membrane on wood surfaces?

- Yes, there are several specific considerations for installing a waterproofing membrane on wood surfaces. Firstly, it is important to ensure that the wood surface is clean, dry, and free from any debris or loose material. This will help in achieving a proper adhesion of the waterproofing membrane. Additionally, it is crucial to choose a membrane specifically designed for wood surfaces, as they may require additional flexibility and resistance to expansion and contraction. It is also recommended to apply a primer or sealer to the wood surface before installing the membrane to improve its adhesion and longevity. Lastly, regular inspection and maintenance of the waterproofing membrane is essential to identify any potential issues and ensure its effectiveness over time.

- Q: Does a waterproofing membrane also protect against moisture and humidity?

- Indeed, moisture and humidity are effectively counteracted by a waterproofing membrane. Its main objective is to establish a shield that thwarts the infiltration of water into surfaces like walls, floors, or roofs. By proficiently obstructing water, it additionally aids in averting the intrusion of moisture and humidity into the safeguarded vicinity. This aspect is of utmost importance in regions susceptible to water-related harm, such as basements, bathrooms, or outdoor structures. The membrane functions as a defensive coating, guaranteeing the interior's dryness and freedom from dampness provoked by moisture or humidity.

- Q: Are waterproofing membranes environmentally friendly?

- Waterproofing membranes can be environmentally friendly depending on the type of membrane used and how it is installed. Some waterproofing membranes are made from recycled materials, which reduces the demand for new resources and helps to minimize waste. Additionally, certain membranes are designed to be durable and long-lasting, which means they won't need to be replaced as frequently, reducing the overall environmental impact. However, it's important to consider the potential negative environmental impacts of waterproofing membranes as well. Some membranes are made from synthetic materials that may release harmful chemicals into the environment during production or when they degrade over time. Additionally, improper installation or disposal of waterproofing membranes can lead to pollution and contamination of soil and water sources. To ensure the environmental friendliness of waterproofing membranes, it is important to choose products that have been certified as sustainable or eco-friendly by reputable organizations. It is also crucial to hire experienced professionals who can install the membranes correctly, minimizing the risk of leaks or damage that could lead to environmental issues. Finally, proper disposal of old or damaged membranes is essential to prevent pollution and ensure responsible waste management. Overall, waterproofing membranes can be environmentally friendly if the right materials are chosen, installation is done properly, and disposal is handled responsibly. It is important to consider the environmental impact of these membranes and make informed choices to minimize any negative effects.

- Q: About asphalt waterproofing membrane

- 5, oil asphalt felt is the asphalt membrane, asphalt membrane is not modified by the coil, usually specifically felt. 6, if it is asphalt-based waterproofing membrane, including non-modified asphalt linoleum, polymer modified SBS coil, oxidized asphalt modified membrane.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on precast concrete surfaces. Firstly, the surface must be thoroughly cleaned and free from any dirt, debris, or loose particles. It is also important to ensure that the precast concrete surface is dry before applying the membrane. Additionally, the type of waterproofing membrane used should be compatible with the precast concrete material to ensure proper adhesion. Proper surface preparation, material compatibility, and ensuring a dry surface are key factors to consider when installing a waterproofing membrane on precast concrete surfaces.

- Q: Can a waterproofing membrane be used on swimming pool decks?

- Yes, a waterproofing membrane can be used on swimming pool decks. It helps to prevent water damage and leakage, ensuring durability and longevity of the deck.

- Q: Can a waterproofing membrane be used in crawl spaces?

- Yes, a waterproofing membrane can be used in crawl spaces. Crawl spaces are vulnerable to moisture and water intrusion, which can lead to issues such as mold, mildew, and structural damage. Using a waterproofing membrane can help protect the crawl space from water damage by creating a barrier against moisture. The membrane is typically installed on the walls and floor of the crawl space, effectively sealing it off from water and preventing water from seeping in. This can be especially beneficial in areas with high water table levels or frequent flooding. Additionally, the waterproofing membrane can also help to improve indoor air quality by preventing the growth of mold and reducing the presence of allergens. It is important to consult with a professional to determine the most suitable waterproofing membrane and installation method for a specific crawl space, as different crawl spaces may have varying requirements.

Send your message to us

High Swelling Bentonite Waterproof Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 300000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords