High Quality Non Asbestos Free Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

Can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, Bestinboards are also applicable to places where high security is needed.

2,Main Features of the (Calcium Silicate Boards)

Product Features:

1.Fire-retardant

2.Thermal-insulated

3.Mildew proof

4.Moisture proof

5.Sound insulated

6.Low moisture and water absorption

7.100% asbestos free and other hazardous substances.

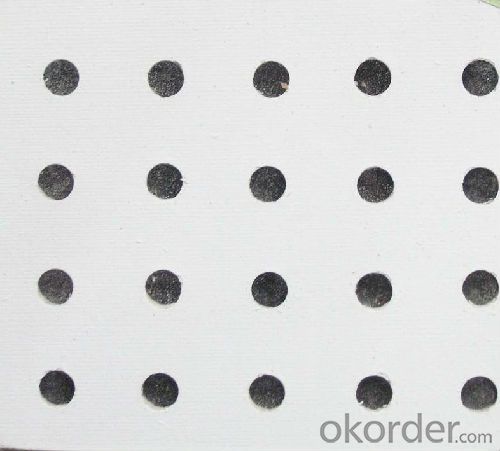

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

| Size | Standard Size | Size:1220*2440*4/6/8/9/10/12/15mm |

| Appearance | Surface | Surface:Un-Sanded/Sanded/Polished; |

| Edge | Square/Recessed/ | |

| Physical Properties | Density | 1.2-1.3g/cm3 |

| Bending Strength | Cross > 16Mpa Parallel 60-70Mpa | |

| Moisture Movement | <0.20% | |

| Water Absorption | < 0.1% | |

| Water Contain | <6%(Under EMS condition) | |

| Thermal Conductivity | 0.12-0.15 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | Interior Ceiling,Interior Patition, Bottom Liner | |

| Products Warranty | More than 20 years |

| Raw Material | Content |

| Cement | 44 % |

| Quartz | 44 % |

| Natural Fiber | 8 % |

| Suspension | 4 % |

| Composition of Finished Product | Content |

| Crystalloid of Calcium Silicate | 52% |

| Quartz | 30% |

| Calcium Carbonate | 10% |

| Cellulose | 8% |

5,FAQ of (Calcium Silicate Boards)

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Trade Term

1. Payment: T/T

2 .Lead time: Samples:15 Working days;

3. Shipping freight are quoted under your requests.

4. Shipping port: Foshan,Guangzhou or Shenzhen port, Mainland China.

5. Discounts: discount based on the order quantity.

Certificate

Products are Calcium Silicate Board (Fiber Cement Board), exterior wall plate, Facade Board and lining board, etc. Our products have passed ISO certificates. CE, TUV Certificates are on progress.

- Q: Calcium silicate board seams with what kind of waterproof tape can be affixed firmly. The

- It is best to hang plastic several times hanging, and so on after the layer of glue dry and then hang a layer of glue, dry after hanging on the glue and other joints on the joint after the best and then linked to a white plastic tape, In the dry environment in the north will not crack, in the south even no problem

- Q: Where to produce 3 m long reinforced fiber calcium silicate board

- Fiber reinforced calcium silicate board is a new building decoration material from 2011 to 2012. The fiber reinforced calcium silicate product has the advantages of light high strength, fireproof insulation, durable, low shrinkage rate, good processing performance and easy surface decoration. , Is widely used in building interior and exterior decoration, ventilation pipes, sound-absorbing panels, fire wall panels and a variety of special-purpose industrial facilities

- Q: What is the material of calcium silicate board

- . Easy construction and processing: Calcium silicate board wall using dry method, keel and sheet metal installation and construction of simple and quick, short duration; can be sawable drill can be cut can be sticky punching, the board can brush paint, paint, Inkjet pattern, paste wallpaper, wall covering, tiles, etc .;

- Q: Toilet with silicon calcium board ceiling, with the general opening device can not open

- It is recommended that you build a drill bit yourself. (At least two), cut it off, leaving about 2 cm (the thickness of calcium silicate board should be less than 2 cm) length, it is welded in a 5mm thickness of the iron plate, The distance between the two drill bits can be determined according to the size of your opening diameter, the middle of the welding should also be a section of about 3 cm length of the impact drill bit as the center of the use of positioning with the use of speed switch with the drill, To slow the way after the operation can be.

- Q: Wood fiber board, calcium silicate board, mineral wool board difference

- In the aspects of health and environmental protection, mineral wool board mineral wool dust particles are easy to inhale the human body, and is a high carcinogen; calcium silicate board it is made of siliceous material (diatomaceous earth, bentonite, quartz powder, etc.) Calcareous material, reinforced fiber as the main raw material, cutting dust and more; VIVA wood fiber cement board is a combination of Portland cement, mineralized wood and non-toxic chemical additives, high pressure made, cutting dust in the cost, Mineral wool board the cheapest, calcium silicate board price center, wood fiber cement board prices higher, but taking into account the health of environmental protection, aesthetics, practicality, life and other factors wood fiber cement board the most cost-effective.

- Q: Is calcium carbonate board containing asbestos poisonous?

- Extremely tiny asbestos dust flew into the air, was inhaled into the human lungs, after 20 to 40 years of incubation period, it is easy to induce lung cancer and other lung diseases.

- Q: I need a tool that can cut calcium silicate board, Bo deep good, where can I buy Wuxi?

- Bo deep specifically for the development of calcium silicate special saw blade, the company used it, the effect is good, the tool does not know if they have

- Q: Calcium silicate board with what saw blade saw faster

- The machine has: fast, high precision, easy maintenance, light operation, noisy, no dust pollution, quality and stability, saw the quality of all kinds of pipe fittings is very good, especially in the mouth and outside the mouth, is the lighting accessories processing Best equipment!

- Q: Home improvement with cotton calcium silicate board how to do?

- If not, for the brand, it is not OK, with gypsum board it, although the moisture-proof fire better, but with some peace of mind. No matter what the material board, as far as possible in the market to cut well, on the one hand is convenient to transport and up and down the elevator convenient, the most important, do not leave cutting dust at home, these cutting dust anywhere in the home can be adsorbed, Will continue to flow out with the air, the decoration of the house although it looks very clean, but there is a confusion is the big dust at home, is the reason. After the installation of the installation, the board of the six sides are made on the closure, first, so that the cutting site is not easy to damp, the second is the board sealed, not because of time for a long time damp, deformation, collapse and yellow.

- Q: Will silicon calcium plate become moldy?

- Short time water seepage, and timely drying, keep the ventilation is not mildew. If there is easy to mold the impurities inside the silicon calcium board and glue, and in the long-term humid, non-ventilated environment, it may be mildew.

Send your message to us

High Quality Non Asbestos Free Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords