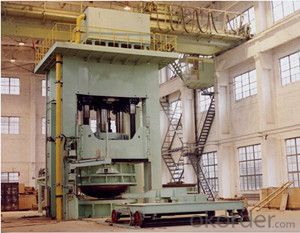

High-Speed Open-Die Forging Hydraulic Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Compared with traditional open-die forging hydraulic presses, TYHI’s high-speed open-die forging hydraulic presses and fully hydraulic rail-bound manipulators are faster, more accurate, more energy-efficient, more environmentally sound and have a higher level of automation. We offer four-column pre-stressed combination frames and double-column oblique-placement pre-stressed combination frames.

Our independently developed 25MN, 35MN, 45MN, 63MN, 80MN, 125MN and 200MN double-column forging hydraulic presses and 430KN, 600KN, 1000KN, 1800KN and 2500KN manipulators all meet international standards. We can submit the relevant project consultation, equipment supply and EPC project.

Moreover, we have produced more than ten high-speed open-die forging hydraulic presses and fully hydraulic rail-bound manipulators. Our 80MN high-speed series of presses have won a China Machinery Industry Science and Technology Progress Award.

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: The development history of punch

- China's archaeological discoveries, as early as 2000 years ago, China has been used for the manufacture of stamping die, proved that the ancient Chinese stamping and stamping die achievements in the world leader.

- Q: What is the relationship between the pressure of the punching machine and the air pressure?

- Upstairs back is very correct. In addition I added that

- Q: How to improve the capacity of a single punching machine

- Speed) is almost impossible, unless the better and more advanced punch, so the cost of investment is too high.

- Q: Why do you want to install a large flywheel on a punching machine?

- The energy required for the punching machine at the time of punching the workpiece is much greater than the energy at other times in the punch.

- Q: Can MnZn ferrite powder be molded with a press?

- (Plus about 8% of the PVA glue granulation, sieve into the particles, drying water control in about 3%, suppress the product.)

- Q: Stamping cartridge how much tonnage punching machine?

- 2, punching machine principle: is driven by the motor flywheel, and through the clutch, transmission gear drive crank connecting rod mechanism to move up and down the slider, driven by the mold on the steel plate molding.

- Q: The hands were stamping machine Qi rush, how much money to pay

- To see you and the company negotiations, you have not encountered such a situation, and your company strength is not clear.

- Q: What safety devices and protective measures must be set for the press?

- Stamping machine operation is characterized by the slider, the next straight and straight movement, placed on the upper and lower mold between the board (with) material stamping, to complete the processing action.

- Q: Stamping and punch the same?

- Stamping and forging are the same plastic processing (or pressure processing), collectively forging.

- Q: How much press is used for the coin

- You can buy a little punch, two hundred tons of pressure on it!

Send your message to us

High-Speed Open-Die Forging Hydraulic Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords