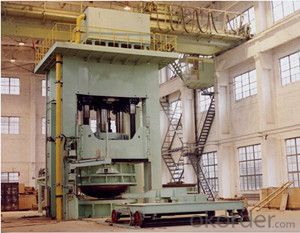

Forging Equipment Punching Hydraulic Press End Cover Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TYHI’s end cover hydraulic presses include 20MN, 40MN and 42MN models. They are mainly used for cold pressing of end covers for various types of tank trucks, and are also used for processes such as formation, drawing and straightening within a range of specifications.

Our 42MN end cover hydraulic presses, the first oil presses using cold pressing formation produced in China, which have filled a niche in the domestic market and also can meet international standards in quality

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: Fenghua robot production of stamping robot, is fully automatic?

- Automatic stacking silos, scattered skid boxes, etc.).

- Q: What is punch workers

- Punch workers is the operation of the punch press operator, referred to as punch workers.

- Q: How to improve the capacity of a single punching machine

- If you want to quickly improve the productivity of a workshop is not anxious to invest in new equipment and automation, capacity is not the higher the better the blind, the better, but with the quality of products produced together.

- Q: 400t punching machine table size

- The main engine factory can be customized for customers to increase the table of the press, specifically to the sales staff consultation.

- Q: Does anyone know that Taiwan is doing punching company which is more famous?

- If the quality of the sale from the price and so on, then consider the three good.

- Q: How do novices use stamping machines?

- 2. Before the official operation by the idle test, to confirm the normal part of the work before the work.

- Q: Can MnZn ferrite powder be molded with a press?

- Of course you can, but need to choose the right tonnage based on your actual product size, you can consider 1.5 tons per square centimeter.

- Q: Punch pressure uneven, in the course of the work out of the product depth of uneven, deep and shallow, how to repair? There is always the sound of the card issued how

- Join the bottom deadline

- Q: The number of tons of automotive stamping machine?

- Some small, such as fine red parts of the safety parts are about 1,000 tons

- Q: Thick PE material after the deformation of the punch how to do

- Cancel each other, and then avoid the deformation of the CNC punch sheet.

Send your message to us

Forging Equipment Punching Hydraulic Press End Cover Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords