Roll Forming Machine in Good Mills E4012

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

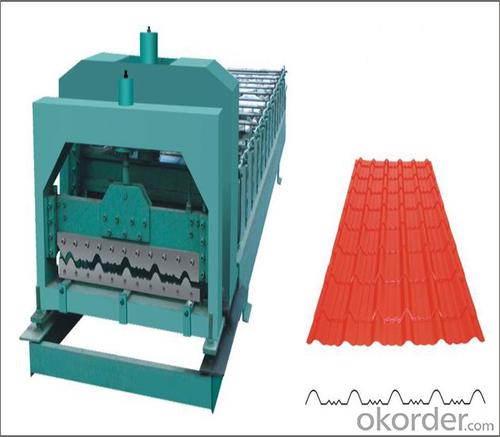

Steel Tile Roll Forming Machine

1.Structure of steel tile roll forming machine:

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1). What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2). Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3). What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4).Is the machine automatic?

Yes, it can be manual and automatic.

5).what policy for broken parts?

within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: Punching machine switch shows the speed of the spm english word is with the table what

- Punch speed display on the SPM said strokes per minute, the Chinese means for the number of times per minute stamping

- Q: What is the principle of the punch clutch?

- one for the pin (cylindrical), through this body will be circular motion

- Q: How do novices use stamping machines?

- 2. Before the official operation by the idle test, to confirm the normal part of the work before the work.

- Q: Punch, punching machine, presses in the processing of any difference

- The working principle of the press punch is designed to convert the circular motion into linear motion, the main motor output, driven flywheel, driven by the clutch gear, crankshaft (or eccentric gear), connecting rod and other operations to achieve the slider linear motion,

- Q: How does this door's profile come out? The

- (5) facade to the level, not New Zealand;

- Q: Is the punching machine stamping die?

- No, the punching machine is the equipment used for the stamping die

- Q: Stamping lathe mold height is what does that mean? What is the use?

- To adjust the modulus of a certain range.

- Q: Manual punching machine operation method?

- The upper mold into the die hole locking, alignment under the mold lock.

- Q: Stamping and punch the same?

- The world's steel, 60 to 70% of the plate, most of which finished by stamping.

- Q: How much press is used for the coin

- a mold can be washed almost ten products, you can make automated production capacity

Send your message to us

Roll Forming Machine in Good Mills E4012

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords