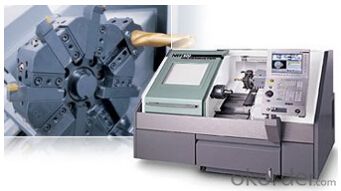

CNC Thread Whirling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Thread whirling machine:Processing threads, worms,screws,pump rotor;

High efficiency, precision, produtivity;

Low Cost.

Thread whirling machine was used to manufacture threaded spindles, rotors for eccentric pumps,progressive cavity pump rotors, vacuum pump rotors, screw type compressors, tie bar threads, ball screws, worm shafts and steering worms.

Whirling is a particular type of milling that is position rotates at high speeds around a slowly turning workpiece. The cutting plane on the tools' cutting edges is adapted to the respective thread pitch by tilting the thread-whirling head around its vertical X-axis. The tool's large tilting range enables users to realize high thread pitches and to cut right-handed and left-handed threads. The radial setting of the whirling head determines the thread depth. The tool's design permits down-cut, conventional and up-cut milling.

Provide a number of advantages over traditional single-point threading, including increased productivity, faster set up times, no extra costs for finishing treatment, superior chip control and increased tool life over conventional tools.

Thread whirling features:

1. The machine is our company's own R & D design, with independent intellectual property rights (with six national patent)

2. Applicable to automobiles, motorcycles, machine tools, gearbox, chemical machinery, plastic machinery, construction machinery and other industries

3. Machine tool used FANUC 0i—Mate—TD system to achieve 4-axis rotary 3-linkage control to X, Z, C axis, whirling milling head axis

4. Machine Tool Spindle Servo Motor is to be the largest ratio 1:100 by harmonic reducer; to achieve the precise positioning of the spindle indexing and powerful cutting

5. Machine milling head used with the international advanced level of machine whirling milling turning, milling in multiple knives without re-grinding

6. Using high precision flexible hydraulic chuck to ensure the worm run out accuracy

7. Tool spindle speed can be adjusted so that user can choose the best cutting speed for work pieces with different diameter and material

8.Automatic involute milling for the machining of both ends of the worm, no need for secondary process

9.The precision of the worm made by CNC machine is up to level six (including all parameters);surface roughness Ra0.8 MAX

10.No limitation of number of threads of worm for Whirlwind milling process, the max helix angle up to ± 25 °

- Q: What is the degree of taper 1:10 in the lathe drawings? How many degrees are there on the lathe?

- Because the slope is 2.8624052261117475326933447284838 °

- Q: What is the material of the lathe tool?

- High-alloy steel, there are 40Cr, the poor manufacturers replaced with 45 steel, cheap but rigid!

- Q: Who will use a hexagonal lathe

- Change the wheel can be out of the four sides of the six sides, very fast!

- Q: CNC machine tool processing characteristics of what, for the answer

- CNC machine tools with its high precision, high efficiency, can adapt to small quantities of complex varieties of complex processing, etc., in the mechanical processing has been increasingly widely used.

- Q: Swan NC simulation FANUC oi system how to return to the lathe, to specific steps

- After returning to zero, you can see the machine coordinates, and the indicator light has been reset to zero.

- Q: CNC lathe radius compensation is how the matter, I do not understand, who helped me talk about it ah

- In some simple car processing (straight to the straight) the arc is no big deal of error, but in some of the relatively high angle, the curvature ... ... especially the complex special surface and the knife when the arc is relatively large

- Q: The structure of the lathe

- ① main shaft box: also known as the head of the box, its main task is to rotate the main motor through a series of transmission mechanism so that the spindle to get the required two different steering speed, while the spindle box separation part

- Q: What is the relationship between surface roughness and machining methods in lathe processing?

- Non-ferrous metal turning surface roughness increased by 0.5 to 1 level.

- Q: CNC lathe with CNC punch there are some differences between CNC machine tools ah

- Can achieve the control of multiple CNC equipment action.

- Q: Please describe the composition and function of the C6150 lathe

- the feed box is equipped with the feed movement of the speed mechanism, adjust its transmission mechanism, you can get the required feed or pitch,

Send your message to us

CNC Thread Whirling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords