High Silica Fiberglass Fabrics - Good Quality and Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction:

High silica fabrics can be used for a long period of time without changing their properties perat the temperature of 1000℃ as it contains more than 96% silica.

2.Properties

No asbestos orceramic,no harm to human

Low thermal conductivity,excellent thermal insulation,high resistance to thermal shock

Superb electric insulation

Inert to majority of chemical reagents

Good flexibility

3.Application

Aerospace,nuclear

Shipbuilding,machinery industry

Refinery

Metallurgy, auto industry

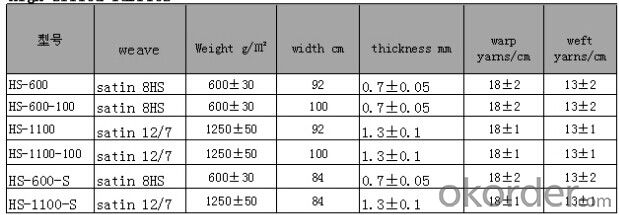

4.Specification

5.Package and Delivery Time.

Packed with carton and pallets.The products will be ready in 15-20 days after the order confirmation.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Can fiberglass fabric be used for reinforcement in aerospace structures?

- Yes, fiberglass fabric can be used for reinforcement in aerospace structures. It is lightweight, has high tensile strength, and offers good resistance to heat and corrosion. These properties make it suitable for applications such as reinforcing composite materials used in aircraft components, spacecraft, and satellites.

- Q: Is fiberglass fabric resistant to chemical degradation?

- Fiberglass fabric is known for its excellent resistance to chemical degradation. Due to its composition of glass fibers, which are impervious to most chemicals, it is highly resistant to the effects of various corrosive substances. Fiberglass fabric can withstand exposure to acids, alkalis, solvents, oils, and other chemicals commonly found in industrial environments without significant degradation. This makes it a preferred choice for applications where chemical resistance is of utmost importance, such as in the manufacturing of chemical storage tanks, pipes, and linings. Additionally, fiberglass fabric's resistance to chemical degradation also contributes to its durability and longevity, making it a reliable material for a wide range of industrial and commercial applications.

- Q: How does fiberglass fabric perform in terms of tensile strength?

- Fiberglass fabric has gained a reputation for its extraordinary tensile strength, positioning it as one of the most robust and durable materials on the market. By interweaving delicate glass fibers, a resilient and sturdy fabric is created, capable of enduring significant tension without breaking or stretching. The tensile strength of this fabric is typically measured in pounds per square inch (psi) or newtons per square meter (N/m2), consistently surpassing the strength of commonly utilized materials like cotton or polyester. This exceptional tensile strength renders fiberglass fabric suitable for a diverse range of applications, including construction, industry, automotive, and even aerospace. In summary, fiberglass fabric's remarkable performance in terms of tensile strength guarantees reliable and enduring solutions across various industries.

- Q: The influence of bag dust removal on dust filtration

- In flannel cloth through teaseler pull scrape with fluff fabric. When the dust is filtered, the dust particles are first captured by a porous layer of fluff, and most of them are supported by a force of latitude and latitude. Subsequently, a dense and dense porous dust layer is formed on the undercoat layer. Due to the large amount of dust cloth Bisubu, so Bisubu high efficiency dust filter. Which is porous media by single fiber, disorderly deposits thicker, has the characteristics of internal filter in a certain extent. Not only the felt itself has a certain ability to filter dust, but also a large amount of dust, so even if the surface does not form a dust layer, but also to ensure a higher dust filter efficiency.

- Q: How does fiberglass fabric perform in filtration efficiency?

- Known for its excellent filtration efficiency, fiberglass fabric is widely used in various filtration applications. This is due to its ability to effectively capture and remove particles from air or liquid streams. The intricate structure of the fabric consists of tiny interwoven fibers, creating a dense network of filtration media. This results in a high surface area and porosity, allowing the fabric to efficiently trap and retain even the smallest particles. The filtration efficiency of fiberglass fabric primarily depends on its fiber diameter, thickness, and density. Smaller fiber diameters and higher fabric densities contribute to better filtration performance as they provide more opportunities for particle capture. Additionally, the fabric's electrostatic properties enhance its filtration efficiency by attracting and trapping charged particles. Fiberglass fabric has been proven highly effective in removing a wide range of contaminants, including dust, pollen, mold spores, bacteria, and certain gases and odors. Its exceptional filtration efficiency has made it a popular choice in applications such as HVAC systems, industrial dust collectors, automotive air filters, and water treatment systems. To summarize, fiberglass fabric excels in filtration efficiency. Its unique structure, combined with its electrostatic properties, allows it to effectively capture and remove particles, making it a reliable option for various filtration applications.

- Q: How is fiberglass fabric used in the production of thermal blankets?

- Fiberglass fabric is used in the production of thermal blankets due to its excellent insulating properties. The fabric is woven with fine fiberglass strands, which create a heat-resistant barrier. This helps to trap and retain heat, making the thermal blanket highly effective in providing warmth and insulation. The fiberglass fabric also adds durability and strength to the blanket, making it long-lasting and suitable for various applications.

- Q: What are the different weights of fiberglass fabric?

- Fiberglass fabric, also referred to as fiberglass cloth, can be found in a variety of weights or thicknesses. The weight of the fabric is determined by measuring the ounces per square yard (oz/yd²) or grams per square meter (g/m²). The range of weights for fiberglass fabric typically spans from 3 oz/yd² (102 g/m²) to 50 oz/yd² (1695 g/m²). The weight of the fiberglass fabric plays a significant role in determining its strength, durability, and suitable applications. For applications that require flexibility, such as boat building, surfboard manufacturing, and automotive parts, lighter weight fiberglass fabrics (3-6 oz/yd² or 102-204 g/m²) are commonly used. These fabrics are also appropriate for repairs and smaller projects. Medium-weight fiberglass fabrics (7-20 oz/yd² or 238-680 g/m²) are often chosen for general-purpose applications like laminating, molding, and reinforcing structures. They offer a good balance between strength and flexibility, making them well-suited for a wide range of projects, including composite manufacturing, construction, and aerospace applications. On the other hand, heavier weight fiberglass fabrics (21-50 oz/yd² or 714-1695 g/m²) are employed in applications that require exceptional strength and rigidity. These fabrics are frequently used in industries such as marine, wind energy, and infrastructure, where materials with high-strength properties are necessary to withstand intense conditions and structural loads. It's worth noting that the specific weight of fiberglass fabric may vary depending on the manufacturer and the intended application. Therefore, it is always advisable to consult the product specifications provided by the manufacturer to ensure the appropriate weight is selected for a specific project.

- Q: Can fiberglass fabric be used for insulation boards?

- Yes, fiberglass fabric can be used for insulation boards. It is lightweight, flexible, and has excellent thermal insulating properties, making it a suitable choice for insulation applications.

- Q: Can fiberglass fabric be used for electrical cables?

- Indeed, electrical cables can make use of fiberglass fabric. Renowned for its exceptional electrical insulation capabilities, fiberglass fabric is well-suited for scenarios necessitating the reduction of electrical conductivity. It can serve as a protective outer layer or insulation within electrical cables, effectively safeguarding against electrical shocks and short circuits. Moreover, fiberglass fabric's resistance to heat, fire, and chemicals amplifies its suitability for electrical cable applications.

- Q: What is an electroplated glass fabric?

- The main strength of cloth on the latitude and longitude direction of fabric, weft or warp for high strength occasions, can also be woven into unidirectional cloth, it can be more roving to warp or weft arrangement, single warp and single weft cloth to cloth. The roving roving is made up of parallel filaments or parallel filaments. According to the composition of glass, roving can be divided into E-GLASS alkali free glass roving and alkali glass roving in C-GLASS.

Send your message to us

High Silica Fiberglass Fabrics - Good Quality and Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords