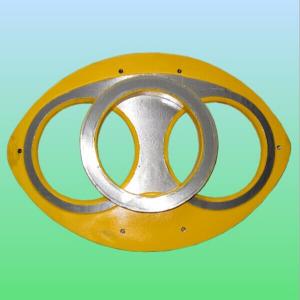

High Quality Tungsten Carbide Cifa Spectacle Wear Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: High Quality Tungsten Carbide Cifa Spectacle Wear Plate

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted CIFA Pump

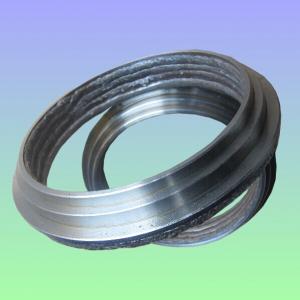

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our High Quality Tungsten Carbide Cifa Spectacle Wear Plate have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs High Quality Tungsten Carbide Cifa Spectacle Wear Plate put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some High Quality Tungsten Carbide Cifa Spectacle Wear Plate according to customers request?

A4: Yes, we can produce High Quality Tungsten Carbide Cifa Spectacle Wear Plate according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts. 1. Size and Compatibility: Ensure that the hydraulic filter or strainer you are installing is the correct size and compatible with the specific make and model of the concrete pump. Using the wrong size or incompatible filter can result in poor filtration or damage to the hydraulic system. 2. Location: The filter or strainer should be installed in a location that allows for easy access and maintenance. It should be positioned in a way that allows for proper filtration of the hydraulic fluid without obstructing the flow. 3. Mounting: The filter or strainer should be securely mounted to prevent any movement or vibration during operation. It is important to follow the manufacturer's instructions for proper mounting techniques and torque specifications. 4. Orientation: Pay attention to the recommended orientation of the filter or strainer. Some filters have specific flow direction requirements, and installing them incorrectly can affect their performance and efficiency. 5. Protection: Consider installing additional protection, such as a guard or shield, to prevent damage to the filter or strainer from external factors like debris or impacts. This can help prolong the lifespan and effectiveness of the filter. 6. Maintenance: Regularly inspect and clean the filter or strainer to ensure proper functioning. Follow the manufacturer's recommended maintenance schedule and procedures for replacement or cleaning to maintain optimal filtration efficiency. It is important to consult the manufacturer's instructions and guidelines for the specific hydraulic filter or strainer being installed, as they may have specific recommendations or requirements unique to their product.

- Q: Which is the best home made concrete pump car?

- The second is heavy Futian Fortaleza, Xiangjian, Xugong, honedeli, the price is high, basically there is no big problem

- Q: What are the specifications for concrete delivery pumps?

- In the cold season, the construction of concrete pump should have anti freeze measures

- Q: What is the difference between concrete pump and ground pump?

- Ground pump only conveying function, the price is cheaper, and now are used to transport mixing machine, the ground pump is a bit uneconomical

- Q: How can one extend the lifespan of concrete pump spare parts?

- One can extend the lifespan of concrete pump spare parts by ensuring regular maintenance, proper lubrication, and cleaning after each use. Additionally, using high-quality spare parts and avoiding overloading or excessive pressure on the pump can also help prolong their lifespan.

- Q: How do concrete pump spare parts help in the pumping process?

- The smooth and efficient operation of a concrete pump relies heavily on spare parts. These parts are crucial for enhancing performance, extending the pump's lifespan, and ultimately saving costs. The use of concrete pump spare parts offers several advantages, one of which is improved pumping efficiency. These parts are meticulously manufactured to ensure the optimal flow of concrete through the pump. For example, the wear plate, wear ring, and S valve all play a crucial role in reducing friction and enhancing pumping performance. By minimizing friction and maintaining a consistent flow, these spare parts prevent blockages and allow for the smooth and efficient pumping of concrete. In addition, concrete pump spare parts are vital for minimizing downtime and reducing maintenance costs. Since the pump operates continuously, wear and tear are inevitable. However, replacing worn-out parts with high-quality spare parts on a regular basis can significantly prolong the pump's lifespan and decrease the need for frequent repairs. Investing in durable and reliable spare parts helps operators avoid unexpected breakdowns and costly repairs, ensuring uninterrupted and efficient pumping operations. Furthermore, concrete pump spare parts contribute to the safety of the pumping process. Components such as the safety valve, hopper grate, and control system all play critical roles in preventing accidents and ensuring the well-being of operators. These spare parts are designed to facilitate the safe and controlled pumping of concrete, reducing the risk of equipment failure and potential hazards. In conclusion, concrete pump spare parts are indispensable in the pumping process as they improve efficiency, minimize downtime and maintenance costs, and enhance safety. By investing in high-quality spare parts, operators can optimize the pump's performance, increase productivity, and achieve long-term cost savings.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Concrete pump spare parts come with warranties and guarantees to ensure their quality and performance. Various manufacturers and suppliers provide these warranties, which typically cover defects in materials or workmanship. The coverage period usually ranges from a few months to a year or more. Furthermore, some suppliers offer guarantees on the performance or durability of their spare parts, providing customers with reassurance. To ensure your protection in case of any issues, it is advisable to inquire about the specific warranty or guarantee terms before purchasing concrete pump spare parts.

- Q: What are the elements of concrete pump and concrete pump truck selection?

- The construction of concrete pump truck has more adaptability and flexibility, boom height, pouring height and cloth radius is bigger, stronger adaptability to construction, in the construction should choose the high concrete pump boom. The concrete pump truck with boom length 28~36m is a large and wide range of products in the market, and about 75%. long arm concrete pump will be the main type of construction. In addition, the concrete pump truck is limited by the automobile chassis capacity. When the boom height exceeds 42m, the cost increases greatly, and it is limited by the space of the construction site, so it is rarely used.

- Q: What are the advantages of using tungsten carbide components in concrete pump spare parts?

- There are several advantages of using tungsten carbide components in concrete pump spare parts. Firstly, tungsten carbide is an extremely hard and durable material, which ensures longer lifespan and increased wear resistance of the components. This means reduced maintenance and replacement costs in the long run. Additionally, tungsten carbide has excellent corrosion resistance, making it suitable for use in harsh and corrosive environments commonly found in concrete pumping applications. Furthermore, tungsten carbide components offer superior strength and toughness, enabling them to withstand high-pressure and heavy-duty operations without compromising performance. Overall, the use of tungsten carbide in concrete pump spare parts leads to improved efficiency, reliability, and cost-effectiveness in concrete pumping operations.

- Q: What is the function of a concrete pump remote control antenna?

- The function of a concrete pump remote control antenna is to wirelessly transmit signals from the remote control device to the concrete pump, allowing the operator to control the pump's functions from a distance.

Send your message to us

High Quality Tungsten Carbide Cifa Spectacle Wear Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords