High Quality Sandwich panel Roll Forming Machinery -PRL-8-SA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Sandwich panel Roll Forming Machinery -PRL-8-SA

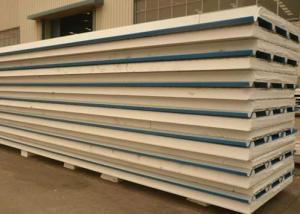

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

Sandwich panel, as a new building material,shows excellent performance on insulation.

It is taking the place of brick to be a main material for building now.

High speed slitting and cut to length can cut steel with thickness from 1mmto 16mm, if no need slitting thickness up to 30mm.

Carry coil→load coil→de-coiling(pressing guide +opener)→entry、rough level→cutting→transition→guide→slitting (waste winding) →looping storage→pre-separating, damping→recoiling →packing→discharging→guide→leveling→fix size (end plate feeding)→cutting→discharging

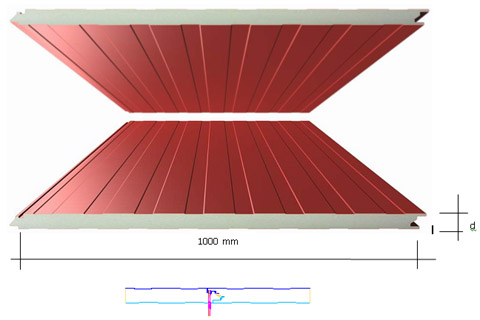

1. The Manufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjust speed)

2. The Thickness Of Sandwich Panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of The Production Line : about 120 meters

5. The Total Power Of The Production Line : 350 KW

6. The Length Of The Double Belt Conveyer : 24m

- Q: Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- The utility model has the characteristics of light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fire prevention, rainproof, long service life, maintenance free, etc., and has been widely popularized and applied.

- Q: Can the oil on the sandwich board be painted?

- Affixed with a layer of decorative panels, sprayed lacquer looks more smooth, whether or not affixed to the decorative panels should be scraped atomic ash, the purpose is to seal the eye brown, the paint film is more full, feel stronger.

- Q: How is the sandwich plate synthesized?

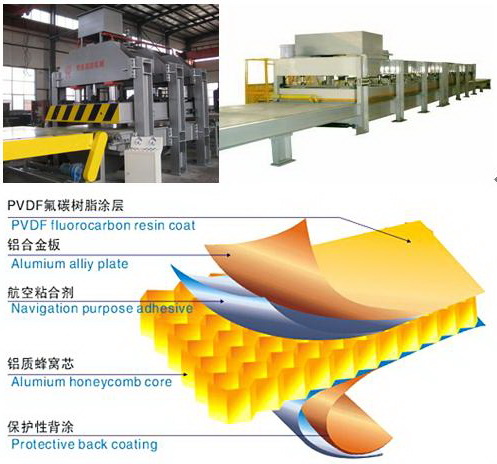

- The forming of the outer steel plate fully takes into account the structural and strength requirements, and takes into account both the beauty and the appearance of the inner layer to form a flat plate to meet various requirements.

- Q: Polyurethane sandwich panel production line?

- Polyurethane sandwich board is polyurethane as the double metal surface and the insulation layer of the single metal surface, non metal surface composite board, commonly used in industrial workshop, warehouse logistics, integrated building wall, roof enclosure system.

- Q: Can the sandwich board adhere to the plaster line?

- Gypsum lines and gypsum board belong to the decoration "surface layer", the same strength of the structure, and therefore can not be based on each other. That is to say, it must be attached to the joinery board below.

- Q: What's the difference between sandwich board and composite board?

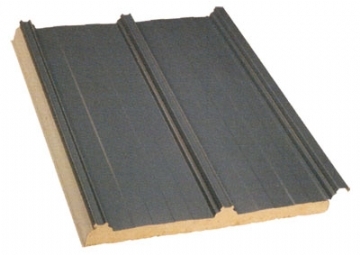

- The metal sandwich panel is made of two layers of metal panels (or other material panels), which are made of heat preservation material and are compounded by adhesive compound or direct foaming.

- Q: Rock wool, color steel sandwich plate production line where good?

- The rockwool sandwich panel production line has a strip of 250mm thick high density rock wool board cutting, automatic transmission, 90 degree flip and saw sandwich plate after forming cutting, automatic stacking, wrapping, can produce different types of wall panels, roof panel, door panel and cold plate etc..

- Q: What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- The common point is that the sandwich panels are all made of hard protective coatings, and the difference is that the materials in the center are different.

- Q: What does color steel sandwich board mean?

- The color steel sandwich panel product is composed of two layers of formed metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- Engineering sandwich plate decoration, wall structure in construction completed, outside the installation of doors and windows, clean air conditioning indoor ceiling above the air supply pipe, various pipes, cable and wiring pipe, pipe insulation after the completion of a special decoration engineering.

Send your message to us

High Quality Sandwich panel Roll Forming Machinery -PRL-8-SA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords