High Pressure Dry Scroll Explosion-proof Vacuum Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Oil Free Scroll Vacuum Pumps

1.Structure of Oil Free Scroll Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Oil Free Scroll Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

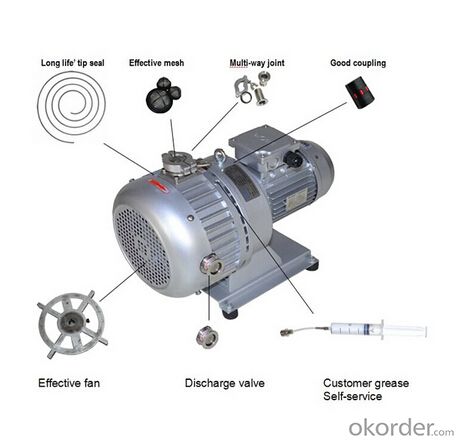

3.Oil Free Scroll Pump Images

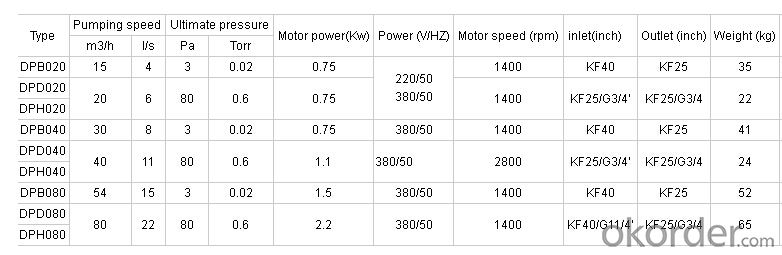

4.Oil Free Scroll Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q: What is the minimum continuous flow of a pump?

- The minimum continuous steady flow can be obtained by test and, in general, the pump supplier will indicate(2) minimum continuous heat limited flow (.API) provides minimum continuous heat limit flow, which means the minimum continuous flow that the pump can maintain and that its operation is not impaired by the temperature rise of the liquid being pumpedMinimum continuous heat limited flow can be calculatedIn the formula, the Pe amount of the fixed axis power is.KW;P pump medium density, kg / m3;

- Q: What does the pump mortar do?

- 1: 2 cement mortar or cement mortar with the same proportion of other components except coarse aggregate in the concrete, the pump piston and the inner wall of the pipeline are fully lubricated, and a layer of lubricating film is formed

- Q: Concrete pump 125 pipe wall thickness

- Concrete pump, also called concrete pump, consists of pump body and pipe. The utility model relates to a machine for continuously conveying concrete along a pipeline by utilizing pressure, which is mainly used for building, bridges and tunnels

- Q: Why can the centrifugal pump hold down the pressure?

- Centrifugal pumps are vertical, horizontal, single-stage, multi-stage, single suction, double suction, self suction and other forms. Vertical centrifugal pump is referred to as submerged pump, molten salt pump and submerged pump. Centrifugal pumps use the impeller to rotate and cause centrifugal motion of the water to work.

- Q: What is the pump delivery? What's the difference between years and years?

- Secondly, the landlord asked the question, although I did not go to the insurance company to practice the operation, but to my four years of learning, as well as internship experience, or can help you analyze, and I hope to help you.Pay is a one-time payment of premium -- all wholesale D sea n

- Q: What does centrifugal pump mean horizontally?

- In other words, pump casing and pump body along the horizontal center of the pump leaves into the upper and lower halves, so that when the pump leaves the pump cover open, you can pump and bearings as a whole pumping out. No need to remove the pipe. I don't know. Do you understand?.

- Q: Is vane pump good or gear pump good?

- The main parts of a gear pump are gears that mesh with each other. The meshing driving gear and the driven gear are respectively arranged on two parallel rotating shafts. Because the gear teeth enter and exit the meshes, the volume of the teeth is changed, and the suction and discharge effect is formed.

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- The power of axial flow pump decreases with the increase of flow rate, and it is a steep curve, so the centrifugal pump starts with an open valve.

- Q: What is the series of pumps? What is the difference between a unipolar and a multilevel? What is the meaning of each "first class"?

- A single-stage pump is a pump with only one impeller. 2, a multistage pump is a pump with two or more impellers. The multistage pump can increase the pressure and lift the head higher. Level 1 means a booster impeller.

- Q: How to calculate the motor power of metering pump?

- The motor power of the metering pump is divided into two parts1. mechanical power, this part of the power metering pump design part will be some data, mainly to control the mechanical structure of the metering pump required power

Send your message to us

High Pressure Dry Scroll Explosion-proof Vacuum Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords