High Quality of Galvanized Steel Coil in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

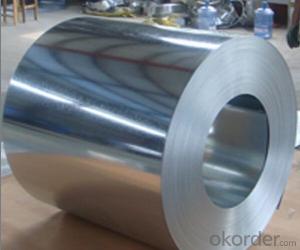

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: How are steel coils used in the manufacturing of telecommunications equipment?

- Steel coils are used in the manufacturing of telecommunications equipment as they are commonly used as a raw material for various components, such as enclosures, cabinets, and brackets. The coils are processed and shaped to create the necessary parts that provide structural support, protection, and stability to the telecommunications equipment.

- Q: Looking for an insight here into what hiking with steel toe-capped boots would be like, as I saw a nice pair of steel toed magnums that I plan to use for my future hiking (which I will be doing a fair amount of in the future). They seemed fairly comfortable, but I am curious into what others have to say and what might be known of this sort of approach. Thanks in advance.

- Steel toed boots are very heavy compared to hiking boots, after a long hike (especially in rough terrain) the extra weight is gonna tire you out. Steel toes are made for things like construction, or doing a task where extra protection of the toe is needed. So it's not ideal, but whatever floats your boat man (better than wearing tennis shoes). I personally have Converse composite toed boots from my airsofting days and since im too cheap to buy dedicated hike boots, I use it for hiking. Its supposedly made for military use and is much lighter than steel toe. But WAIT!!! lets say you dont have a gun or knife and you run into a pissed off Sasquatch, a steel toe boot too the nutz would do well in puttin the hurt on the dude.

- Q: Maybe it is obvious. But i have thought alot about it.I thought steel at a cool temperature was unbreakable. I am not one for science or physics or engineering (i am a political science major). But i don't understand why the planes that struck the world trade center on 9-11 didn't just dent the side and fall,How did the place break the steel? Was it the velocity? Is steel easily broken?I realized that i wasn't taught how the planes broke the steel, and that no one ever asked. I searched the web and i couldn't find the answer or even anyone who had asked the question before.(i don't care about conspiracy theories, i just want scientific facts)

- 1 nothing is unbreakable! 2 it is a question of velocity not that the plane was going very fast but! the difference between an explosion and a detonation is if the flame front is faster or slower than 1000 meter per second If you burn Hydrogen it burns fast, more than 1000 meter per second at that speed a plastic pen like those you use every day will puncture through a steel 2X4 used in modern building walls it is not thick steel but it is still steel! and the plastic piece is hardly deformed Those talking about aviation fuel... this is long, very long after the fact Guru

- Q: Hi all.I'm working on a project which requires about 3 steel pipes at 25mm in diametre and about a foot each in length.The qualities I need with the steel is that:1. I need it to be easy enough to weld together2. I need to be able to drill holes through them with a basic drill (I could buy different bits, that's fine)3. I need the steel to be able to take short intense repeated bursts of strain through said holes4. The lighter the steel the better5. Could I please have a ballpark figure for price. I can't imagine such a small amount of steel would cost too muchThank you in advance for your replyRegardsSean

- Sprinkler pipe or black pipe. Designed for fire suppression systems, it is often used for coping on skateboard and BMX fixtures. Not sure of the price, you could probably pick up some scrap from a plumbing supply house or a sprinkler installer. Can't imagine the cost to be more than $10

- Q: Can steel coils be bent or formed into different shapes?

- Steel coils have the capability to be bent or molded into diverse forms. Typically, steel coils are produced from flexible flat rolled steel, allowing for easy manipulation. The process of bending entails exerting force upon the steel coil, resulting in a transformation of shape and the adoption of different configurations. This can be accomplished through a variety of techniques, including cold or hot bending, as well as the utilization of specialized machinery such as a press brake. By skillfully applying the appropriate amount of force and heat, steel coils can be bent or molded into an extensive array of shapes, encompassing curves, angles, and intricate geometries. This adaptability in shaping steel coils renders them exceptionally versatile for an array of applications, spanning construction, manufacturing, automotive, and numerous other industries.

- Q: What are the different methods of edge trimming steel coils?

- There are several methods for edge trimming steel coils, including shearing, slitting, laser cutting, and milling. Each method has its own advantages and is chosen based on factors such as the desired precision, speed, and cost-effectiveness of the trimming process.

- Q: What are the factors to consider when selecting a supplier for steel coils?

- When selecting a supplier for steel coils, there are a few key factors to consider. Firstly, the quality of the steel coils is crucial. It is important to assess the supplier's reputation, certifications, and track record for delivering high-quality products. Secondly, pricing and cost-effectiveness play a significant role. Comparing prices and negotiating favorable terms with different suppliers is essential to ensure competitive pricing. Additionally, the supplier's reliability and ability to meet delivery schedules must be thoroughly evaluated. Timely delivery is vital to avoid disruptions in production. Lastly, considering the supplier's location, proximity to the manufacturing facility, and their overall customer service and support are also important factors to take into account.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q: How are steel coils used in the manufacturing of railway wagons?

- Steel coils are used in the manufacturing of railway wagons as they provide structural strength and stability to the wagons. These coils are typically used to construct the wagon's frame, ensuring durability and the ability to carry heavy loads. Additionally, steel coils are also used in the manufacturing of various components such as axles, couplers, and suspension systems, further enhancing the wagon's performance and safety.

- Q: When maintaining a japanese knife: Is a honing steel still necessary if I have a fine 3000/8000 grit whetstone?which do you prefer?

- A steel is to clean off an edge and remove any bends on the bevel, it is not directly for sharpening as it removes no material from the knife (or should not). A whetstone, however fine, does remove material. A steel to maintain an edge, a stone to restore an edge. They are different items for different purposes.

Send your message to us

High Quality of Galvanized Steel Coil in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords