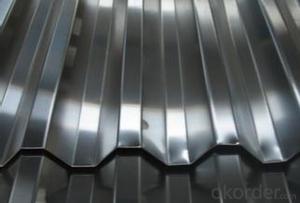

High Quality of Corrugated Galvanized Steel Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- My cats will eat their food from a stainless steel bowl but only drink their water from a plastic or ceramic bowl. This is a little far fetched, but maybe they get scared when they see their reflection in it. You know like when you look into a stainless steel toaster, you're face looks all distorted -- maybe the water in addition to the stainless steel is scary to them. The stainless steel pet dishes I have claim to be non-microbial (bacteria free) or something like that. Maybe whatever they use for this is affecting the taste of the water. The food, on the other hand, since it already has a flavor (water has no flavor), maybe it's not so noticeable.

- Q: I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- I think so, I've never played classical, only acoustic and electric but my neighbor has a classical and he has all steel strings on it.

- Q: What are the dimensions of steel coils used in the storage tank industry?

- Steel coils used in the storage tank industry come in various dimensions, depending on the specific requirements of the tank being manufactured. Generally, these coils are available in different sizes and thicknesses. The width of the steel coils can range from approximately 600 millimeters to 2,400 millimeters. Similarly, the length can vary from a few meters to tens of meters. The thickness of the coils can also differ, typically ranging from 1.5 millimeters to 10 millimeters or more. Factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank determine these dimensions. Consequently, the tank manufacturer or designer would determine the specific dimensions for a given storage tank project, following industry standards and project specifications.

- Q: How can I arbitrate quality of steel before purchasing it??

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. The reaction to these processes can determine whether the steel be fit for the purpose required.

- Q: Is steel framing eco friendly? Why or why not.

- No because unlike the timber in trees, it is not a renewable resource and takes much heat energy to produce.

- Q: How do steel coils contribute to durability and longevity in products?

- The durability and longevity of products are greatly enhanced by steel coils, mainly because of their strength, stability, and resistance to corrosion. Firstly, steel is widely known for its exceptional strength, making it the perfect material for applications where durability is crucial. Steel coils, which are essentially tightly rolled steel, add strength and structural integrity to products. The stability offered by steel coils is another important factor in improving product durability. The tightly rolled structure of the coils ensures that they maintain their shape and resist deformation even under heavy loads or extreme conditions. This stability is particularly significant in industries like construction and automotive, where products need to withstand rigorous usage for long periods of time. Furthermore, steel coils have excellent resistance to corrosion, primarily due to the presence of protective coatings. These coatings, such as zinc or other metallic alloys, act as a barrier against moisture and environmental elements that cause rust and degradation. By preventing corrosion, steel coils help extend the lifespan of products, making them more durable and reliable. Moreover, steel coils can be customized to meet specific requirements, such as different thicknesses, widths, or surface finishes. This versatility allows manufacturers to tailor the steel coils to their desired application, ensuring optimal performance and longevity in their products. To sum up, steel coils contribute to the durability and longevity of products through their strength, stability, corrosion resistance, and customization capabilities. By incorporating steel coils into various industries and applications, manufacturers can ensure that their products last longer and provide greater reliability to consumers.

- Q: What are the different methods of steel coil surface cleaning?

- There are several different methods of steel coil surface cleaning, including mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials or brushes to remove dirt, rust, and other contaminants from the surface of the steel coil. Chemical cleaning involves using chemicals or solvents to dissolve or remove contaminants from the surface. High-pressure water cleaning uses water jets at high pressures to remove dirt and debris from the surface. Each method has its own advantages and is chosen based on the specific requirements and condition of the steel coil.

- Q: How do steel coils perform in high-pressure applications?

- Due to their robust and durable nature, steel coils are highly effective in high-pressure scenarios. The exceptional tensile strength of steel enables it to endure immense pressure without any distortion or breakdown. Moreover, steel coils are specifically engineered to retain their shape and structural integrity even under the most extreme pressure, making them ideal for deployment in a wide range of high-pressure applications such as hydraulic systems, pressure vessels, and industrial machinery. Furthermore, the exceptional resistance of steel coils to corrosion and high temperatures further augments their performance in high-pressure environments. These qualities, coupled with their reliability and capacity to withstand high pressure, render steel coils the preferred choice for industries seeking resilient and efficient equipment.

- Q: What are the dimensions of steel coils used in the energy sector?

- The dimensions of steel coils used in the energy sector can vary depending on the specific application and requirements. However, commonly used dimensions for steel coils in the energy sector range from 0.5mm to 5.0mm in thickness, with widths typically ranging from 600mm to 2000mm. The diameter of the coil can vary as well, with commonly used sizes ranging from 1000mm to 2200mm. These dimensions are chosen to ensure the coils can be easily transported, processed, and utilized in various energy sector applications such as power plants, oil and gas pipelines, and renewable energy projects. It is important to note that these dimensions are not fixed and can be customized based on specific project requirements.

- Q: How are steel coils used in the manufacturing of industrial valves?

- Steel coils are used in the manufacturing of industrial valves as they provide the necessary material for constructing the valve bodies and other components. The steel coils are processed and shaped into the desired form, ensuring the valves are durable and can withstand high pressure and temperature conditions.

Send your message to us

High Quality of Corrugated Galvanized Steel Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords