High-Quality Insulating Fire Brick - Sintered Mullite Fire Lining Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

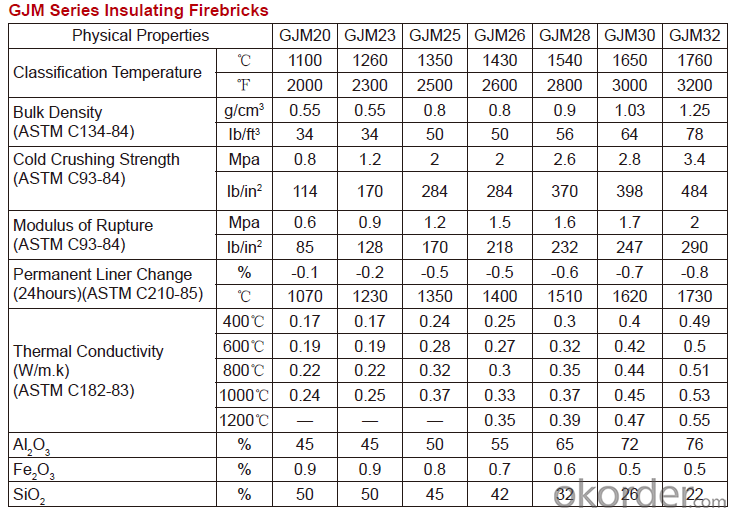

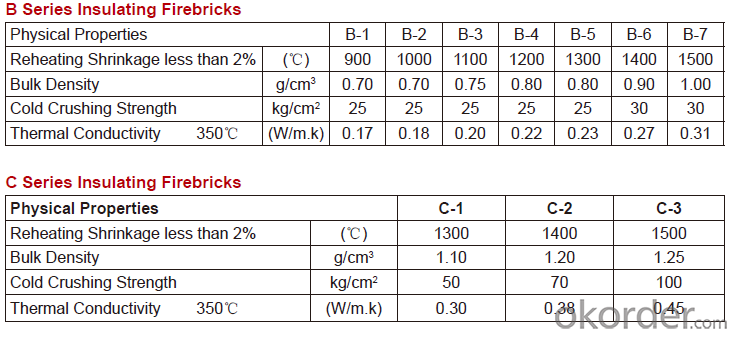

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in the construction of heat shields?

- Yes, insulating fire bricks can be used in the construction of heat shields. Insulating fire bricks are specially designed to handle high temperatures and provide excellent thermal insulation. They can effectively absorb and distribute heat, making them ideal for creating heat shields that protect against intense heat and prevent it from reaching sensitive areas or materials.

- Q: What is the difference between cement foamed thermal insulation board and thermal insulating brick?

- The main difference between cement foamed thermal insulation board and insulating brick is that the shape is different, one is plate, and the other is brick. Both are new walls to achieve the effect of energy conservation and insulation.

- Q: Can insulating fire bricks be used in the construction of pottery molds?

- Yes, insulating fire bricks can be used in the construction of pottery molds. Insulating fire bricks are made from lightweight refractory materials that have excellent heat insulation properties. These bricks are specifically designed for applications that require high temperatures, such as pottery kilns. When constructing pottery molds, it is important to have materials that can withstand the intense heat of the kiln. Insulating fire bricks can withstand temperatures up to 3000°F (1650°C), making them suitable for pottery mold construction. They provide insulation to prevent heat loss and maintain consistent temperatures inside the kiln, which is essential for achieving the desired firing results. Furthermore, insulating fire bricks can be easily shaped and cut to fit the desired mold design. They are also lightweight, which makes them easier to handle during the mold construction process. Additionally, the insulating properties of these bricks help to reduce energy consumption by preventing excessive heat loss, making them cost-effective in the long run. Overall, insulating fire bricks are a suitable choice for constructing pottery molds due to their ability to withstand high temperatures, provide insulation, and be easily shaped to fit specific designs.

- Q: Can insulating fire bricks be used in refractory mortar?

- Yes, insulating fire bricks can indeed be used in refractory mortar. Insulating fire bricks are lightweight and have low thermal conductivity, which makes them ideal for applications where heat insulation is required, such as in kilns, furnaces, and other high-temperature environments. Refractory mortar, on the other hand, is specifically designed to withstand high temperatures and provide a strong bond between fire bricks or other refractory materials. By using insulating fire bricks in refractory mortar, you can achieve both heat insulation and structural integrity in your application.

- Q: Can insulating fire bricks be used for insulation in petrochemical plants?

- Yes, insulating fire bricks can be used for insulation in petrochemical plants. Insulating fire bricks are known for their excellent thermal properties, including low thermal conductivity and high resistance to heat transfer. These properties make them suitable for use in high-temperature environments such as petrochemical plants, where insulation is crucial to prevent heat loss and maintain optimal operating conditions. Additionally, insulating fire bricks are lightweight and have good mechanical strength, making them easy to install and durable in industrial settings. They are also resistant to chemical corrosion, which is essential for petrochemical plants that handle various corrosive substances. Therefore, insulating fire bricks can effectively provide insulation and contribute to energy efficiency and safety in petrochemical plants.

- Q: Can insulating fire bricks be used in thermal insulation panels?

- Insulating fire bricks possess the capability to be utilized in thermal insulation panels. These bricks are manufactured using lightweight materials, including clay, alumina, and silica, which exhibit exceptional thermal insulation properties. They are engineered to withstand extreme temperatures and deliver insulation across a range of applications, such as furnaces, kilns, and industrial equipment. When integrated into thermal insulation panels, insulating fire bricks aid in diminishing heat transfer and enhancing energy efficiency. They effectively trap and reflect heat, preventing its escape or entry into the insulated area. This renders them suitable for insulating walls, roofs, and other structures that necessitate thermal insulation. Furthermore, the installation of insulating fire bricks is hassle-free, as they can be cut or shaped to accommodate various spaces and configurations. This flexibility allows for personalized customization and ensures a secure and efficient insulation barrier. It should be noted that while insulating fire bricks provide exceptional thermal insulation, their effectiveness in sound insulation may be limited. Therefore, additional soundproofing measures may be required if soundproofing is also a requirement. In conclusion, insulating fire bricks represent a dependable choice for thermal insulation panels, offering superior insulation performance, durability, and versatility.

- Q: Can insulating fire bricks be used in the construction of lime production kilns?

- Yes, insulating fire bricks can be used in the construction of lime production kilns. Lime production kilns require high temperatures to convert limestone into lime, and insulating fire bricks are known for their ability to withstand and retain high temperatures. These bricks have high insulating properties, allowing the kiln to reach the desired temperature quickly and efficiently, while also minimizing heat loss during the production process. Insulating fire bricks are also lightweight and easy to handle, making them suitable for use in the construction of lime production kilns. Additionally, these bricks have good thermal shock resistance, meaning they can withstand rapid temperature changes without cracking or breaking, which is crucial in the kiln environment. Overall, the use of insulating fire bricks in the construction of lime production kilns can help optimize the efficiency and effectiveness of the lime production process.

- Q: Can insulating fire bricks be used in DIY projects?

- Yes, insulating fire bricks can certainly be used in DIY projects. These bricks are lightweight and have excellent thermal insulation properties, making them suitable for various applications. They are commonly used in projects such as constructing wood-fired ovens, fire pits, kilns, and even for building the walls of a forge. Insulating fire bricks can withstand high temperatures and are resistant to thermal shock, making them a reliable choice for DIY enthusiasts who want to create heat-resistant structures. They are also easy to cut and shape, allowing for customization according to specific project needs.

- Q: Can insulating fire bricks be used in the construction of thermal storage units?

- Insulating fire bricks are indeed capable of being utilized in the construction of thermal storage units. These bricks possess a specific design that grants them exceptional insulation properties, rendering them an optimal selection for thermal storage units. They are crafted from lightweight materials with low thermal conductivity, enabling them to retain heat for extended durations. Thermal storage units serve the purpose of storing and discharging heat energy as required. The inclusion of insulating fire bricks aids in minimizing heat loss from the stored energy, thus ensuring efficient and effective thermal storage. Their remarkable insulation properties facilitate superior heat retention, thereby diminishing the necessity for continuous heating or cooling. Furthermore, insulating fire bricks exhibit durability and can endure high temperatures, making them highly suitable for the construction of thermal storage units. They can withstand the thermal strains and temperature fluctuations that arise during the heating and cooling cycles of the unit, thereby guaranteeing its longevity and dependability. In conclusion, due to their outstanding insulation properties, durability, and ability to withstand high temperatures, insulating fire bricks are an appropriate and advantageous choice for the construction of thermal storage units.

- Q: Can insulating fire bricks be used as a lining for kiln cars?

- Yes, insulating fire bricks can be used as a lining for kiln cars. Insulating fire bricks are designed to have excellent thermal insulation properties, which make them suitable for use in high-temperature applications such as kilns. They are capable of withstanding high temperatures without cracking or crumbling, making them an ideal choice for lining kiln cars. Additionally, their lightweight nature makes them easy to handle and install, reducing the overall weight and energy consumption of the kiln. Overall, insulating fire bricks can provide effective insulation and protection for kiln cars, helping to improve their efficiency and longevity.

Send your message to us

High-Quality Insulating Fire Brick - Sintered Mullite Fire Lining Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords