Insulating Fire Brick - Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

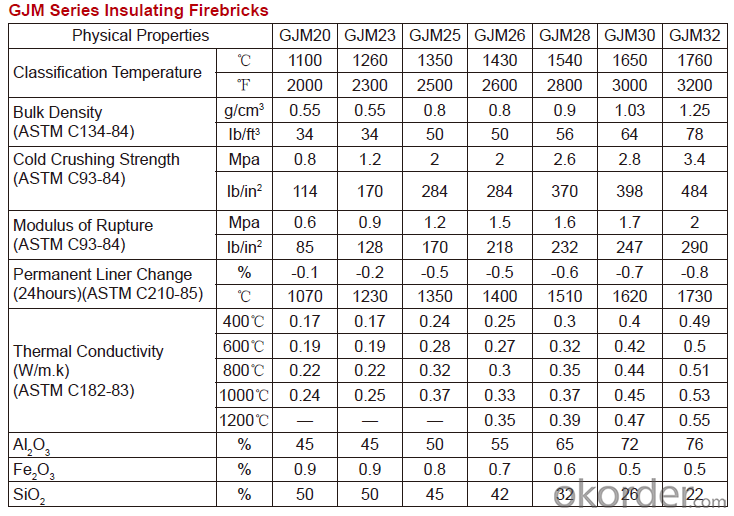

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in the construction of brick ovens?

- Brick ovens can indeed utilize insulating fire bricks. These specialized bricks possess exceptional thermal insulation characteristics, which make them highly suitable for applications that require efficient heat retention, such as brick ovens. Crafted from lightweight refractory materials, these bricks exhibit a lower density compared to standard clay bricks, thereby minimizing heat loss and enhancing energy efficiency. When constructing a brick oven, it is crucial to contemplate the insulation layer responsible for preserving and evenly disseminating heat throughout the oven. Insulating fire bricks can be employed to create this insulation layer, typically positioned between the inner cooking chamber and the outer oven layer. By utilizing these bricks, heat transfer to the outer layer is minimized, preventing excessive heat dissipation and ensuring the oven attains and maintains the desired high temperatures essential for baking or cooking. Apart from their impressive thermal insulation properties, insulating fire bricks also exhibit remarkable resistance to thermal shock. This signifies their ability to endure abrupt temperature changes without cracking or fracturing. This quality is particularly valuable in brick ovens, as they frequently encounter significant temperature fluctuations during the baking process. To sum up, insulating fire bricks are a fitting and highly recommended choice for constructing brick ovens due to their thermal insulation properties, lightweight composition, and resilience to thermal shock. By utilizing these bricks, a well-insulated and efficient oven can be created, capable of achieving and sustaining high temperatures for optimal baking or cooking outcomes.

- Q: Do insulating fire bricks require maintenance?

- Yes, insulating fire bricks require minimal maintenance. They are designed to withstand high temperatures and are resistant to cracking or crumbling. However, regular cleaning to remove any debris or buildup is recommended to maintain their insulating properties and extend their lifespan.

- Q: How do insulating fire bricks affect the overall insulation efficiency of a process?

- Insulating fire bricks significantly enhance the insulation efficiency of a process by providing a high level of thermal resistance. These bricks have low thermal conductivity and can withstand high temperatures, effectively minimizing heat transfer and reducing energy loss. This improved insulation helps maintain consistent and controlled temperatures, leading to increased energy efficiency and reduced fuel consumption in various industrial processes.

- Q: Can insulating fire bricks be used in high-temperature insulation boards?

- Indeed, high-temperature insulation boards can utilize insulating fire bricks for their thermal insulation needs. These bricks are specifically engineered to endure extreme temperatures while offering exceptional thermal insulation. They find widespread use in various applications demanding insulation under elevated temperatures, including kilns, furnaces, and fireplaces. By incorporating insulating fire bricks into high-temperature insulation boards, one can effectively reduce heat loss and uphold a consistent temperature. Nevertheless, it is crucial to assess the particular prerequisites of the application and verify the compatibility of the insulating fire bricks with the insulation board material and installation technique.

- Q: Are insulating fire bricks porous?

- Yes, insulating fire bricks are porous. Porosity is a characteristic of insulating fire bricks that allows them to have low thermal conductivity. These bricks are made from ceramic materials and contain a high percentage of tiny air pockets or voids, which trap and slow down the transfer of heat. This porosity also makes the bricks lightweight and resistant to thermal shock. The ability of the insulating fire bricks to retain heat and provide effective insulation is directly linked to their porous structure.

- Q: Do insulating fire bricks require a protective coating?

- A protective coating is not always essential for insulating fire bricks, given their inherent ability to endure high temperatures and provide insulation. These bricks are composed of lightweight refractory materials with exceptional thermal conductivity characteristics, enabling them to retain heat and inhibit heat transfer. However, in certain instances where the bricks may be exposed to corrosive substances or aggressive chemicals, it may be advisable to apply a protective coating to enhance their longevity and resilience. Ultimately, the necessity of a protective coating hinges on the particular application and surrounding environment in which the insulating fire bricks are employed.

- Q: The insulation layer destroyed after use of cement paste and tiling

- Put on the insulating layer and paste it with cement.Some students worry about the insulation layer and the wall adhesive strength is not enough, do not worry about, now developers are building exterior insulation and then on top of the tiling. Because after finishing the insulation layer, the contractor should check the construction to do a pullout test, the purpose is to prevent the strength can not meet the requirements.

- Q: Are insulating fire bricks resistant to oil and gas?

- Insulating fire bricks are generally resistant to oil and gas. These bricks are made from high temperature materials such as alumina and silica, which provide excellent thermal insulation properties and can withstand high temperatures. They are commonly used in industries where there is exposure to heat, such as in furnaces, kilns, and fireplaces. However, it is important to note that the resistance to oil and gas can vary depending on the specific composition and manufacturing process of the insulating fire bricks. Some bricks may have a higher resistance to oil and gas compared to others. To ensure the best resistance to oil and gas, it is recommended to use insulating fire bricks that are specifically designed for such applications. These bricks are often referred to as oil and gas resistant fire bricks and are manufactured with additional additives or coatings that enhance their resistance to these substances. In summary, while insulating fire bricks are generally resistant to oil and gas, it is advisable to use bricks that are specifically designed for such applications to ensure optimal performance and longevity.

- Q: Can insulating fire bricks be used in the construction of cremation chambers?

- Insulating fire bricks have the capability to be utilized in the construction of cremation chambers. These bricks are manufactured using lightweight materials such as vermiculite or perlite, which possess remarkable insulating properties. These properties render them suitable for high-temperature applications like cremation chambers, where they are instrumental in maintaining a consistent and controlled temperature. The utilization of insulating fire bricks in the construction of cremation chambers yields numerous benefits. Firstly, these bricks aid in enhancing energy efficiency by minimizing heat loss. This subsequently leads to reduced fuel consumption and cost savings. Secondly, the insulating properties of these bricks ensure that a stable temperature is maintained within the cremation chamber, which is crucial for achieving efficient and complete combustion of the deceased. Furthermore, these bricks are lightweight and easy to handle, thereby facilitating a more convenient and efficient construction process. Nevertheless, it is worth noting that although insulating fire bricks can be employed in the construction of cremation chambers, they are typically used in conjunction with refractory fire bricks. Refractory fire bricks are fabricated from materials such as clay or silica, which possess the ability to withstand exceedingly high temperatures. These bricks are installed in areas of the cremation chamber that come into direct contact with the flames, while insulating fire bricks are utilized in areas that require insulation. In conclusion, insulating fire bricks are a suitable choice for the construction of cremation chambers due to their excellent thermal insulation properties and ability to contribute to the efficient and controlled operation of the cremation process.

- Q: Are insulating fire bricks fire-rated?

- Yes, insulating fire bricks are fire-rated. They are specifically designed to withstand high temperatures and provide excellent thermal insulation in various applications. These bricks are made from a special type of ceramic material with low thermal conductivity, which allows them to retain heat and prevent it from transferring to the surrounding areas. This property makes them highly resistant to fire and helps protect the structures they are used in. Insulating fire bricks are commonly used in furnaces, kilns, fireplaces, and other high-temperature environments where fire protection is crucial.

Send your message to us

Insulating Fire Brick - Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords