High Quality Insulating Fire Brick GJM23-26 Insulation Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

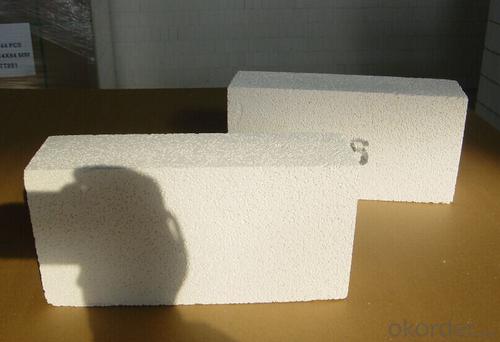

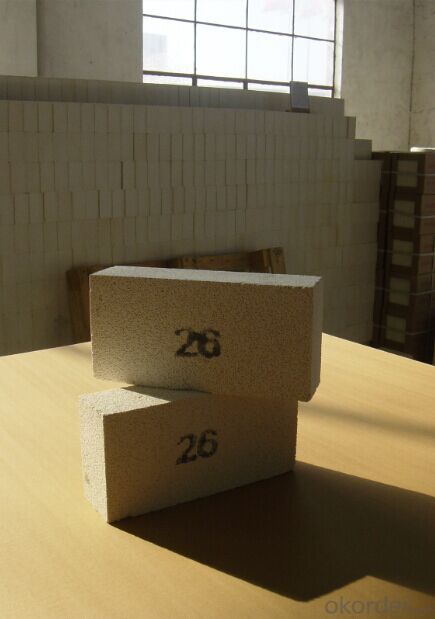

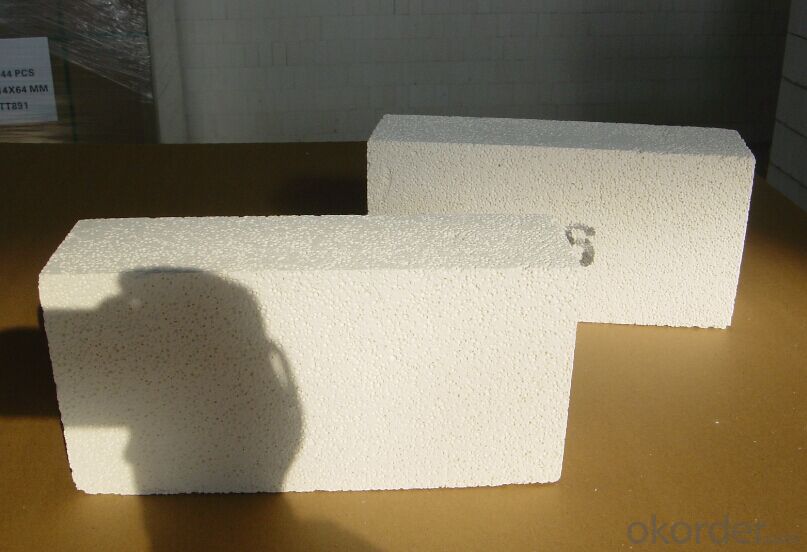

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is mullite insulation brick?

- Mullite brick, according to different density can be divided into: lightweight mullite brick and heavy mullite brick;

- Q: Are there any special requirements for the use of raw materials in thermal insulation brick production equipment? What about the raw materials?

- . The control system needs to break, pouring the completion of data acquisition and process control of production site, steam curing process monitoring and control, production line of aerated brick Deyi heavy do better and integrity, production operation management etc..

- Q: Do insulating fire bricks require any special sealing or caulking?

- Insulating fire bricks generally do not require any special sealing or caulking. These bricks are designed to have low thermal conductivity, which means they already provide good insulation on their own. However, in certain specific applications or when exposed to extreme temperatures, some sealing or caulking may be necessary to ensure optimal performance and prevent any heat loss or damage. It is recommended to consult the manufacturer's guidelines or a professional for specific sealing requirements in such cases.

- Q: Can insulating fire bricks be used for insulation in foundries?

- Yes, insulating fire bricks can be used for insulation in foundries. Insulating fire bricks are specifically designed to have high thermal resistance and low thermal conductivity, making them ideal for applications where insulation is required. In foundries, where high temperatures are involved, insulating fire bricks can be used to line the walls, floors, and roofs to reduce heat loss and improve energy efficiency. They can also help to maintain a uniform temperature throughout the foundry, ensuring consistent heat distribution and preventing heat loss to the surroundings. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for insulation in foundries.

- Q: Are insulating fire bricks suitable for insulation in petrochemical plants?

- Yes, insulating fire bricks are suitable for insulation in petrochemical plants. Insulating fire bricks are made from lightweight materials with high insulating properties, such as ceramic fibers or lightweight refractory aggregates. These bricks are designed to have low thermal conductivity, which allows them to effectively reduce heat transfer and provide insulation in high-temperature environments. In petrochemical plants, where processes involve the handling of flammable and hazardous materials, maintaining proper insulation is crucial for safety and efficiency. Insulating fire bricks can withstand high temperatures and provide excellent thermal insulation, helping to reduce heat loss and minimize energy consumption. Furthermore, insulating fire bricks are resistant to chemical corrosion, making them suitable for use in petrochemical plants where exposure to corrosive chemicals is common. These bricks are also durable and have good mechanical strength, allowing them to withstand the harsh conditions in petrochemical plants. Overall, insulating fire bricks are an ideal choice for insulation in petrochemical plants due to their high-temperature resistance, excellent thermal insulation properties, chemical resistance, and durability.

- Q: Are insulating fire bricks resistant to reducing atmospheres?

- Insulating fire bricks exhibit resistance to reducing atmospheres. These bricks have been specifically engineered to endure elevated temperatures and harsh circumstances, including exposure to reducing atmospheres. They are crafted from top-notch refractory materials that possess the capability to withstand the detrimental effects of reducing atmospheres, which may encompass gases like carbon monoxide or hydrogen. Due to their low thermal conductivity and superior insulation properties, insulating fire bricks prove to be exceptional in scenarios where reducing atmospheres are present. They efficiently shield the surrounding areas from heat transfer and safeguard the structure against potential harm. Furthermore, these bricks boast remarkable mechanical strength and outstanding resistance to thermal shock, enabling them to retain their integrity even in the face of challenging conditions. In conclusion, the durability of insulating fire bricks coupled with their capacity to endure high temperatures and harsh environments confirms their resistance to reducing atmospheres.

- Q: What sizes are insulating fire bricks available in?

- Insulating fire bricks are available in various sizes, including standard sizes like 9" x 4.5" x 2.5" and 9" x 4.5" x 3". However, custom sizes can also be manufactured to meet specific requirements.

- Q: Can insulating fire bricks be used in the construction of coke ovens?

- The use of insulating fire bricks in the construction of coke ovens is indeed possible. These bricks are specifically designed to endure extreme temperatures and offer exceptional thermal insulation. Coke ovens, which typically operate at around 2000 degrees Fahrenheit, necessitate materials that can withstand such conditions. The low thermal conductivity of insulating fire bricks effectively hinders heat transfer between the interior and exterior of the oven. This feature helps to maintain the necessary high temperatures for coal carbonization in the coke oven, while simultaneously minimizing heat loss. Moreover, insulating fire bricks possess a lightweight composition and high strength, which makes them ideal for coke oven construction. Their lightweight nature facilitates easier installation and reduces the overall weight of the structure. Additionally, their high strength ensures that they can endure the harsh operating conditions of the coke oven without cracking or crumbling. In conclusion, insulating fire bricks are a suitable choice for constructing coke ovens due to their ability to withstand high temperatures, provide thermal insulation, and offer durability.

- Q: Can insulating fire bricks be used in residential applications, such as fireplaces or ovens?

- Residential applications like fireplaces or ovens can indeed utilize insulating fire bricks. These bricks are specifically designed for enduring high temperatures and providing outstanding thermal insulation. They are crafted from lightweight materials like clay or alumina, which possess low thermal conductivity. This attribute assists in retaining the heat within the fireplace or oven, enhancing efficiency and reducing energy consumption. Moreover, insulating fire bricks exhibit exceptional resilience against thermal shock, enabling them to withstand sudden temperature fluctuations without cracking or breaking. Additionally, these bricks are non-combustible, ensuring they can withstand the intense temperatures produced in fireplaces or ovens without posing a fire hazard. Consequently, insulating fire bricks are a suitable option for residential applications requiring high temperatures and thermal insulation.

- Q: Can insulating fire bricks be used in glass melting furnaces?

- Yes, insulating fire bricks can be used in glass melting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in furnaces where glass is melted.

Send your message to us

High Quality Insulating Fire Brick GJM23-26 Insulation Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords