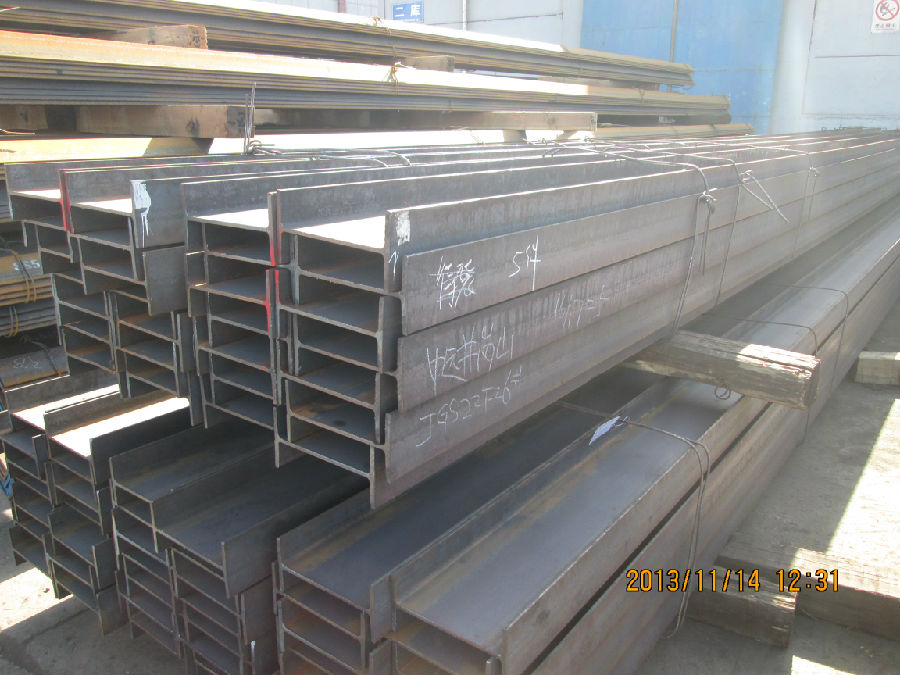

High Quality Hot Rolled Steel Jis Standard H Beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

roduct Description:

Specifications of Hot Rolled Steel H-beam

1. Standard: GB

2. Grade: Q235 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Category | model (height*width)/ (mm×mm) | Section size/mm | Cross-section area/cm2 | Theoretical Weight/(kg/m) | Moment of inertia/cm4 | radius/cm | Section modulus/cm3 | |||||||

H | B | t1 | t2 | r | Ix | Iy | ix | iy | Wx | Wy | ||||

HW | 100×100 | 100 | 100 | 6 | 8 | 8 | 21.59 | 16.9 | 386 | 134 | 4.23 | 2.49 | 77.1 | 26.7 |

125×125 | 125 | 125 | 6.5 | 9 | 8 | 30.00 | 23.6 | 843 | 293 | 5.30 | 3.13 | 135 | 46.9 | |

150×150 | 150 | 150 | 7 | 10 | 8 | 39.65 | 31.1 | 1620 | 563 | 6.39 | 3.77 | 216 | 75.1 | |

175×175 | 175 | 175 | 7.5 | 11 | 13 | 51.43 | 40.4 | 2918 | 983 | 7.53 | 4.37 | 334 | 112 | |

200×200 | 200 | 200 | 8 | 12 | 13 | 63.53 | 49.9 | 4717 | 1601 | 8.62 | 5.02 | 472 | 160 | |

200 | 204 | 12 | 12 | 13 | 71.53 | 56.2 | 4984 | 1701 | 8.35 | 4.88 | 498 | 167 | ||

250×250 | 244 | 252 | 11 | 11 | 13 | 81.31 | 63.8 | 8573 | 2937 | 10.27 | 6.01 | 703 | 233 | |

250 | 250 | 9 | 14 | 13 | 91.43 | 71.8 | 10689 | 3648 | 10.81 | 6.32 | 855 | 292 | ||

250 | 255 | 14 | 14 | 13 | 103.93 | 81.6 | 11340 | 3875 | 10.45 | 6.11 | 907 | 304 | ||

HM | 150×100 | 148 | 100 | 6 | 9 | 8 | 26.35 | 20.7 | 995.3 | 150.3 | 6.15 | 2.39 | 134.5 | 30.1 |

200×150 | 194 | 150 | 6 | 9 | 8 | 38.11 | 29.9 | 2586 | 506.6 | 8.24 | 3.65 | 266.6 | 67.6 | |

250×175 | 244 | 175 | 7 | 11 | 13 | 55.49 | 43.6 | 5908 | 983.5 | 10.32 | 4.21 | 484.3 | 112.4 | |

HN | 100×50 | 100 | 50 | 5 | 7 | 8 | 11.85 | 9.3 | 191.0 | 14.7 | 4.02 | 1.11 | 38.2 | 5.9 |

125×60 | 125 | 60 | 6 | 8 | 8 | 16.69 | 13.1 | 407.7 | 29.1 | 4.94 | 1.32 | 65.2 | 9.7 | |

150×75 | 150 | 75 | 5 | 7 | 8 | 17.85 | 14.0 | 645.7 | 49.4 | 6.01 | 1.66 | 86.1 | 13.2 | |

175×90 | 175 | 90 | 5 | 8 | 8 | 22.90 | 18.0 | 1174 | 97.4 | 7.16 | 2.06 | 134.2 | 21.6 | |

200×100 | 198 | 99 | 4.5 | 7 | 8 | 22.69 | 17.8 | 1484 | 113.4 | 8.09 | 2.24 | 149.9 | 22.9 | |

200 | 100 | 5.5 | 8 | 8 | 26.67 | 20.9 | 1753 | 133.7 | 8.11 | 2.24 | 175.3 | 26.7 | ||

250×125 | 248 | 124 | 5 | 8 | 8 | 31.99 | 25.1 | 3346 | 254.5 | 10.23 | 2.82 | 269.8 | 41.1 | |

250 | 125 | 6 | 9 | 8 | 36.97 | 29.0 | 3868 | 293.5 | 10.23 | 2.82 | 309.4 | 47.0 | ||

300×150 | 298 | 149 | 5.5 | 8 | 13 | 40.80 | 32.0 | 5911 | 441.7 | 12.04 | 3.29 | 396.7 | 59.3 | |

300 | 150 | 6.5 | 9 | 13 | 46.78 | 36.7 | 6829 | 507.2 | 12.08 | 3.29 | 455.3 | 67.6 | ||

350×175 | 346 | 174 | 6 | 9 | 13 | 52.45 | 41.2 | 10456 | 791.1 | 14.12 | 3.88 | 604.4 | 90.9 | |

350 | 175 | 7 | 11 | 13 | 62.91 | 49.4 | 12980 | 983.8 | 14.36 | 3.95 | 741.7 | 112.4 | ||

400×150 | 400 | 150 | 8 | 13 | 13 | 70.37 | 55.2 | 17906 | 733.2 | 15.95 | 3.23 | 895.3 | 97.8 | |

HT | 100×50 | 95 | 48 | 3.2 | 4.5 | 8 | 7.62 | 6.0 | 109.7 | 8.4 | 3.79 | 1.05 | 23.1 | 3.5 |

97 | 49 | 4 | 5.5 | 8 | 9.38 | 7.4 | 141.8 | 10.9 | 3.89 | 1.08 | 29.2 | 4.4 | ||

100×100 | 96 | 99 | 4.5 | 6 | 8 | 16.21 | 12.7 | 272.7 | 97.1 | 4.10 | 2.45 | 56.8 | 19.6 | |

125×60 | 118 | 58 | 3.2 | 4.5 | 8 | 9.26 | 7.3 | 202.4 | 14.7 | 4.68 | 1.26 | 34.3 | 5.1 | |

120 | 59 | 4 | 5.5 | 8 | 11.40 | 8.9 | 259.7 | 18.9 | 4.77 | 1.29 | 43.3 | 6.4 | ||

125×125 | 119 | 123 | 4.5 | 6 | 8 | 20.12 | 15.8 | 523.6 | 186.2 | 5.10 | 3.04 | 88.0 | 30.3 | |

150×75 | 145 | 73 | 3.2 | 4.5 | 8 | 11.47 | 9.0 | 383.2 | 29.3 | 5.78 | 1.60 | 52.9 | 8.0 | |

147 | 74 | 4 | 5.5 | 8 | 14.13 | 11.1 | 488.0 | 37.3 | 5.88 | 1.62 | 66.4 | 10.1 | ||

150×100 | 139 | 97 | 4.5 | 4.5 | 8 | 13.44 | 10.5 | 447.3 | 68.5 | 5.77 | 2.26 | 64.4 | 14.1 | |

142 | 99 | 4.5 | 6 | 8 | 18.28 | 14.3 | 632.7 | 97.2 | 5.88 | 2.31 | 89.1 | 19.6 | ||

150×150 | 144 | 148 | 5 | 7 | 8 | 27.77 | 21.8 | 1070 | 378.4 | 6.21 | 3.69 | 148.6 | 51.1 | |

147 | 149 | 6 | 8.5 | 8 | 33.68 | 26.4 | 1338 | 468.9 | 6.30 | 3.73 | 182.1 | 62.9 | ||

175×90 | 168 | 88 | 3.2 | 4.5 | 8 | 13.56 | 10.6 | 619.6 | 51.2 | 6.76 | 1.94 | 73.8 | 11.6 | |

171 | 89 | 4 | 6 | 8 | 17.59 | 13.8 | 852.1 | 70.6 | 6.96 | 2.00 | 99.7 | 15.9 | ||

175×175 | 167 | 173 | 5 | 7 | 13 | 33.32 | 26.2 | 1731 | 604.5 | 7.21 | 4.26 | 207.2 | 69.9 | |

172 | 175 | 6.5 | 9.5 | 13 | 44.65 | 35.0 | 2466 | 849.2 | 7.43 | 4.36 | 286.8 | 97.1 | ||

200×100 | 193 | 98 | 3.2 | 4.5 | 8 | 15.26 | 12.0 | 921.0 | 70.7 | 7.77 | 2.15 | 95.4 | 14.4 | |

196 | 99 | 4 | 6 | 8 | 19.79 | 15.5 | 1260 | 97.2 | 7.98 | 2.22 | 128.6 | 19.6 | ||

200×150 | 188 | 149 | 4.5 | 6 | 8 | 26.35 | 20.7 | 1669 | 331.0 | 7.96 | 3.54 | 177.6 | 44.4 | |

Usage & Applications of Hot Rolled Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Steel H-beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do Steel H-Beams perform in terms of sound insulation?

- Steel H-beams do not perform well in terms of sound insulation. While they provide excellent structural support, their open design allows sound to easily pass through them, making them a poor choice for soundproofing applications.

- Q: Are steel H-beams suitable for convention halls?

- Yes, steel H-beams are commonly used in convention halls due to their strength, durability, and ability to support heavy loads. They provide structural stability and can be easily prefabricated and installed, making them a suitable choice for convention hall construction.

- Q: What is the weight of a typical steel H-beam?

- The weight of a typical steel H-beam can vary depending on its size and dimensions. However, as a general guideline, an H-beam weighing around 33 pounds per foot (or approximately 49 kilograms per meter) is considered typical. It is important to note that the weight can vary based on factors such as the specific alloy of steel used, the manufacturing process, and any additional modifications or treatments applied to the H-beam. For accurate and precise weight information, it is recommended to refer to the manufacturer's specifications or consult with a structural engineer.

- Q: Can steel H-beams be used for supporting communication towers?

- Certainly, communication towers can indeed be supported by steel H-beams. Construction projects often rely on steel H-beams due to their impressive strength and ability to bear heavy loads. These beams offer exceptional structural support and can endure substantial forces, making them an ideal choice for supporting communication towers. The H-shaped design of these beams ensures a larger surface area, enhancing stability and reducing the likelihood of collapse. What's more, steel H-beams boast a lengthy lifespan and demand minimal maintenance, making them both cost-effective and dependable for supporting communication towers.

- Q: Can steel H-beams be used in the construction of automotive showrooms or dealerships?

- Yes, steel H-beams can be used in the construction of automotive showrooms or dealerships. Steel H-beams are commonly used in commercial construction due to their strength and durability. They can provide structural support for large open spaces, allowing for flexible and spacious showroom designs. Additionally, steel H-beams can withstand heavy loads, making them suitable for displaying cars and other vehicles in dealerships.

- Q: How do you calculate the deflection limits for steel H-beams?

- To determine the deflection limits for steel H-beams, several factors must be considered. Typically, the deflection limits are established by relevant building codes or industry standards. The steps below outline the general process of calculating these limits: 1. Find the applicable building code or industry standard: Building codes or industry standards, such as the American Institute of Steel Construction (AISC) code, usually specify the deflection limits. These codes provide guidelines based on the intended use of the structure. 2. Gather information about the H-beam: Collect the necessary details about the H-beam, including dimensions, material properties, and support conditions. This information can be obtained from the manufacturer or relevant design resources. 3. Calculate the moment of inertia: The moment of inertia measures the beam's resistance to bending. It is determined by the beam's dimensions and geometry. The moment of inertia plays a critical role in determining the deflection of the beam. 4. Identify the applied load: Determine the load or loads that will act on the H-beam. This may include dead loads, live loads, wind loads, or other specified loads according to design requirements. 5. Use the appropriate deflection formula: The choice of deflection formula depends on the type of loading and support conditions. Common formulas include the Euler-Bernoulli beam equation, which assumes linear elastic behavior, and the Timoshenko beam equation, which considers shear deformations. 6. Calculate the maximum allowable deflection: Utilize the deflection formula to input relevant parameters such as applied load, beam properties, and support conditions. Calculate the deflection at various points along the beam and compare these values to the deflection limits specified in the building code or industry standard. 7. Ensure compliance with deflection limits: If the calculated deflection exceeds the specified limits, adjustments must be made to the beam's dimensions, material, or support conditions. This may involve increasing the beam size, using a stronger material, or adding additional support. It is important to note that calculating deflection limits for steel H-beams can be a complex process that may require the expertise of a structural engineer or designer. Adhering to the applicable building codes and industry standards is crucial to ensure project safety and structural integrity.

- Q: Are steel H-beams resistant to pests like termites?

- Steel H-beams possess a high level of resistance against pests such as termites. In contrast to wooden beams, which are prone to termite infestations, steel H-beams do not serve as a food source for termites nor create a suitable environment for their thriving. Termites primarily feed on cellulose, a substance present in wood. However, as steel is not composed of organic material, termites are not attracted to it. Furthermore, steel H-beams are impervious to moisture damage and decay, which are other factors that can attract and sustain termite colonies. Consequently, incorporating steel H-beams in construction markedly diminishes the risk of termite infestation and potential harm to the structure.

- Q: How do Steel H-Beams contribute to the overall life cycle assessment of a structure?

- Steel H-beams contribute to the overall life cycle assessment of a structure in several ways. Firstly, these beams are commonly used as structural components in buildings, bridges, and other infrastructure projects due to their high strength and durability. The use of steel H-beams in construction helps to ensure the longevity and stability of the structure, which is a crucial aspect of the life cycle assessment. Additionally, steel H-beams have a high recyclability rate, meaning that they can be easily recovered and reused at the end of their life cycle. This promotes sustainability and reduces the environmental impact of the structure. Steel is one of the most recycled materials globally, and the use of H-beams contributes to the circular economy by minimizing waste and conserving natural resources. Moreover, the manufacturing process of steel H-beams has become more energy-efficient and environmentally friendly over the years. Advanced technologies, such as electric arc furnaces and energy recovery systems, are employed to reduce energy consumption and greenhouse gas emissions during production. This improvement in manufacturing practices positively impacts the life cycle assessment by reducing the embodied energy and carbon footprint of the structure. Furthermore, steel H-beams are known for their design flexibility and adaptability. They can be easily modified or replaced, allowing for future structural modifications or repurposing of the building. This adaptability extends the life cycle of the structure and reduces the need for complete demolition and reconstruction, which would have a significant environmental impact. In summary, steel H-beams contribute to the overall life cycle assessment of a structure by providing strength, durability, and stability. Their high recyclability, energy-efficient manufacturing, and design flexibility promote sustainability and reduce environmental impacts. By considering the use of steel H-beams in construction projects, we can enhance the overall performance and longevity of structures while minimizing their ecological footprint.

- Q: How do steel H-beams perform in high-traffic areas?

- Due to their inherent strength and durability, steel H-beams are highly effective in high-traffic areas. The design of the H-beam provides outstanding load-bearing capacity, making it suitable for supporting heavy loads and withstanding bending or breaking caused by frequent traffic pressure. The performance of H-beams in high-traffic areas is further enhanced by their steel construction. Steel is renowned for its superior strength and resilience, enabling H-beams to endure the constant stress and impact associated with heavy traffic. Additionally, they are resistant to corrosion, which is particularly important in areas exposed to moisture or harsh weather conditions. Furthermore, steel H-beams offer versatility in terms of design and construction. They can be easily customized to accommodate different traffic loads and project requirements. This flexibility ensures that H-beams can meet the specific needs of high-traffic areas, whether it be a bridge, highway, or industrial facility. In conclusion, steel H-beams are an excellent choice for high-traffic areas due to their exceptional strength, durability, and versatility. They can effectively handle heavy loads, resist bending or breaking, and withstand the demanding conditions of frequent traffic.

- Q: Are steel H-beams suitable for use in the construction of cultural centers or theaters?

- Yes, steel H-beams are suitable for use in the construction of cultural centers or theaters. Steel H-beams are widely used in the construction industry due to their high strength and durability. They provide excellent load-bearing capabilities, making them ideal for supporting the weight of large structures such as cultural centers or theaters. Additionally, steel H-beams have the advantage of being able to span long distances, allowing for more open and flexible designs in these types of buildings. Moreover, steel is a sustainable and environmentally-friendly material, making it a preferred choice for construction projects. Overall, steel H-beams are a reliable and suitable option for the construction of cultural centers or theaters.

Send your message to us

High Quality Hot Rolled Steel Jis Standard H Beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords