Carpi Waterproof Polyethylene Geomembrane with Colorful for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Waterproof Polyethylene Geomembrane

Waterproof Polyethylene are the preferred products for lining projects requiring low permeability , corrosion protection

exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy , vapor barriers and waste water treatment in the line of industry and aquaculture and agriculture projects.

Main Features of Waterproof Polyethylene Geomembrane:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

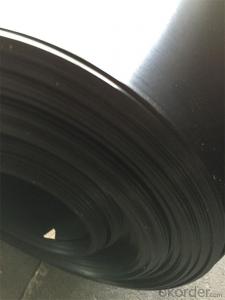

Waterproof Polyethylene Geomembrane Images

Waterproof Polyethylene Geomembrane Specification :

| Thickness | 0.12mm-4.0mm |

| Length | 50m/roll,100m/roll,150m/roll or as your choice |

| Width | 5.0m-7.0m or as your choice |

| Color | White/Black/Blue/Green,mainly black |

| Material | HDPE |

| Delivery port | Qingdao |

| Package: | woven bag or as customers' requests |

| Product time | 2-20 days |

| Features | 1.Good physical and mechanic performance |

| 2.High tearing resistance, strong deformation adaptability | |

| 3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance | |

| 4.Good adaptability to high and low temperature, non-toxicity, long service life | |

| 5.Good waterproof, drainage, anti-seepage and damp proof effects | |

| 6.Complete width and thickness specifications, low cost and easy installation. | |

| Note | We can do as your demand,please feel free to contact us for more information |

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q: What are the precautions for the construction of the slope area of the cesspit?

- The construction method of geotextile/geomembrane: 1 flatness: ±2cm/m2, flat and straight; 2 compactness: 95%, after grinding, pave geomembrane on the surface; 3 vertical and horizontal gradient: Longitudinal and transverse slope should be above 2%, boundary and structure of the landfill bottom must be beneficial to diversion of leachate; 4 cleanness: No roots, rubble, gravel, concrete particles, such as sharp edges shall appear within vertical depth of 2.50cm . Climate requirements while paving: 1. Temperature: 5 - 40℃ is appropriate. Taking into account thermal expansion and cold contraction of the geomembrane, according to experience, when the weather is cold, geomembrane pavement should be tight; in hot weather should be loose; but it should be noted that, in summer, high temperature should be avoided at noon. 2 wind and rain: If the wind scale is over force 4 wind or it's raining, the construction should be stopped; When wind is lessened, it is proper to hold down geomembrane with sandbag so as to facilitate construction. Construction and installation of HDPE geomembrane: 1 construction and installation process of HDPE geomembrane. 2 tailor and transportation: According to the records of laying base measurement , cutting large bundle number of geomembrane should be marked and recorded and then carried to construction site according to their number.

- Q: Is electrothermal?film safe?

- Electrothermal?film is safe, general leakage protectors can't be installed as they always trip, so they are gradually eliminated in the heating market. But it has the advantage of power saving, because the carbon heat energy conversion rate is very high, but the process is not good - too thin, which is easy to cause electric leakage. Although metal heating cable is safe, it costs much electricity. It is recommended that you use carbon fiber heating cable, which is a product integrating the advantages of electrothermal?film and metal heating cable, safe and energy saving.

- Q: Why composite geo-membrane can not be used in underground garage?

- Composite geo-membrane was invented in China, applied in the The South-to-north Water Diversion Project with good anti-seepage effect. While there are no composite geo-membrane in foreign countries. It has also been widely used in subway?tunnel and other underground constructions. Of course, it can be used in underground garage , but you must choose the appropriate specifications. It is recommended to use 300g/1.0mm/300g composite geo-membrane. The following are the details. Composite geo membrane is geotechnical impermeable material made of plastic film as anti-seepage material and non-woven fabrics. Its waterproof performance mainly depends on the performance of plastic film. Impermeable plastic film at home and abroad are mainly polyvinyl chloride (PVC) and polyethylene (PE), which are Polymer chemistry flexible material with smaller proportion, good extensibility and high?adaptability?to the?deformation. Corrosion resistance, low temperature resistance, good anti-frost?property. The main mechanism is to block earth dam leakage passage by imperviousness of plastic film and bear hydraulic?pressure and adapt to deformation of dam with greater tensile strength and elongation. Non-woven geotextile is also a kind of macromolecule staple fibre chemical material shaped through acupuncturing or hot sticking, having high tensile strength and extensibility. Combined with plastic film, it can not only increases the tensile strength and anti-puncture ability of plastic film, but also increase the friction coefficient of contact surface and make the composite geo-membrane and packaging layer stable as the non-woven fabrics surface becomes rough. At the same time, they have good corrosion resistance to bacteria and chemical action, not afraid of acid, alkali, salt erosion, high seepage coefficient.

- Q: Are geomembranes resistant to punctures from human activities?

- Yes, geomembranes are designed to be resistant to punctures caused by human activities. They are typically made from strong materials like high-density polyethylene or PVC, which provide excellent puncture resistance. However, the level of resistance may vary depending on the specific type and thickness of the geomembrane used.

- Q: What materials are commonly used to make geomembranes?

- Some common materials used to make geomembranes include high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM).

- Q: How do geomembranes contribute to the preservation of archaeological sites?

- Geomembranes contribute to the preservation of archaeological sites by acting as a protective barrier against moisture, contaminants, and erosion. They are used to cover and line excavation areas, preventing the infiltration of water that can damage artifacts and structures. Geomembranes also help to stabilize the soil and prevent erosion, ensuring the structural integrity of the site. Additionally, they can be used to create controlled environments for the storage and preservation of delicate artifacts, allowing for long-term conservation.

- Q: Home color film and the film pvc wallpaper What is the difference?

- Ingredients: Wall membrane: Using natural materials, free of PVC, free of formaldehyde, benzene, toluene and other toxic substances. Wallpaper: Use paper | PVC construction method: Wall membrane: Technology low, easy to glue, white-wall film and adhesive properties, easy mosaic, wallpaper: high requirements, high material loss. Decorative: Wall membrane: Rich in texture, in three-dimensional, the preparation of patterns and colors with any class, you can paint, can change color when recoated. Wallpaper: Surface gloss, colorful patterns. You can not paint. . Can not change the color; repairability: Wall membrane: For multiple brushing renovation, it can be partially repaired. Wallpaper; can not repair, can only be partial or total replacement. Stability: Wall membrane: Do not fade, mildew, non-toxic odor-free, anti-moth. Wallpaper: fade, mildew, shedding, odor, anti moisture not good. Life: Wall membrane: 30 years (can be changed within 8 colors) Wallpaper: 5 years Economy: Wall membrane: Simple construction, low loss, can be repeatedly brushing, long service life. Wallpaper: Parquet, while trimming losses high, short life.

- Q: What are the limitations of geomembranes in high-velocity flow conditions?

- One limitation of geomembranes in high-velocity flow conditions is their susceptibility to damage or tearing. The force of the flowing water can exert significant pressure on the geomembrane, leading to punctures or tears if not properly designed or installed. Additionally, geomembranes may experience displacement or uplift due to the high velocity flow, compromising their effectiveness in containing fluids or preventing seepage. Overall, geomembranes may not provide adequate protection or containment in extreme high-velocity flow situations.

- Q: Are geomembranes suitable for use in hydraulic barrier applications?

- Yes, geomembranes are suitable for use in hydraulic barrier applications. Geomembranes are impermeable liners that can effectively prevent the flow of water or other liquids, making them a reliable choice for creating hydraulic barriers. They are commonly used in various applications such as landfills, reservoirs, canals, and wastewater treatment facilities to control and manage water flow. With their durability, flexibility, and resistance to chemicals, geomembranes provide an effective solution for preventing seepage and leakage in hydraulic barrier systems.

- Q: What are the considerations for geomembrane installations in areas with high wind gusts?

- When installing geomembranes in areas with high wind gusts, several considerations need to be taken into account. Firstly, the selection of a suitable geomembrane material is crucial. It should be strong, durable, and capable of withstanding the force exerted by strong winds. Additionally, the installation method must be carefully planned to ensure proper anchoring and securing of the geomembrane to prevent it from being lifted or damaged by wind gusts. The use of appropriate fasteners, weights, or ballast systems can be employed to provide stability and prevent wind uplift. Adequate preparation of the subgrade, such as compacting and leveling, is also important to minimize the risk of wind-induced damage. Regular inspections and maintenance of the geomembrane installation are necessary to identify and address any potential issues caused by high wind gusts. Overall, attention to material selection, installation techniques, and ongoing monitoring are crucial considerations for successful geomembrane installations in areas prone to high wind gusts.

Send your message to us

Carpi Waterproof Polyethylene Geomembrane with Colorful for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords