Reinforced Polypropylene Geomembrane - 0.15-3mm HDPE/LDPE Geomembrane Price for Liner Piscine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane Introduction:

HDPE Smooth Face geomembrane are the preferred products for lining projects requiring

low permeability , corrosion protection , exceptional chemical and ultraviolet resistance properties ,

which makes them extremely cost-effective for many applications such as waste landfill ,

storage reservoirs ,canals , powr plants in energy , vapor barriers , and waste water treatment

in the line of industry and aquaculture and agriculture projects.

Geomembrane Specification:

Thickness | 0.12mm-4.0mm |

Length | 50m/roll,100m/roll,150m/roll or as your choice |

Width | 5.0m-7.0m or as your choice |

Color | White/Black/Blue/Green,mainly black |

Material | HDPE |

Delivery port | Qingdao |

Package: | woven bag or as customers' requests |

Product time | 2-20 days |

Features | 1.Good physical and mechanic performance |

2.High tearing resistance, strong deformation adaptability | |

3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance | |

4.Good adaptability to high and low temperature, non-toxicity, long service life | |

5.Good waterproof, drainage, anti-seepage and damp proof effects | |

6.Complete width and thickness specifications, low cost and easy installation. | |

Note | We can do as your demand,please feel free to contact us for more information |

Geomembrane Usage:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

HDPE geomembrane liner technical of ASTM test GM 13 standard:

No. | Item | Test Value | |||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 1.8mm | 2.0mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.94 | |||||||

2 | Strength at yield,N/mm | 11 | 15 | 18 | 23 | 27 | 30 | 38 | 45 |

3 | Strength at break ,N/mm | 21 | 28 | 33 | 43 | 51 | 57 | 71 | 85 |

4 | Elongation at yield,% | 13 | |||||||

5 | Elongation at break,% | 700min | |||||||

6 | Tear Resistance N | 93 | 125 | 156 | 187 | 219 | 249 | 311 | 373 |

7 | Puncture Resistance N | 263 | 352 | 440 | 530 | 618 | 703 | 881 | 1059 |

8 | Stress Crack Resistance, hrs | 400 | |||||||

9 | Carbon Black Content, % | 2.0-3.0 | |||||||

Carbon Black Dispersion | 1 or 2 | ||||||||

10 | Standard OTI Min | 100 | |||||||

High Pressure OTI Min | 400 | ||||||||

11 | Impact Cold Crack at -70°C | Pass | |||||||

12 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | |||||||

13 | Dimensional Stability (%) | ±2 | |||||||

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

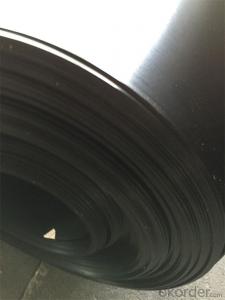

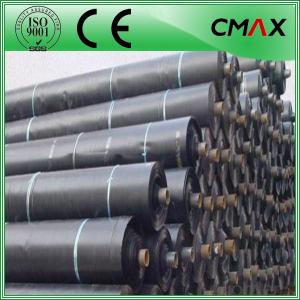

Gemembrane Show:

- Q: What is the one-way membrane?

- The architectural glass film. It can only see the outside from the inside, but the outside can not see the inside.

- Q: What geomembrane is used in the dewatering ditch

- DMD geomembrane two cloths film one film D non-woven fabrics M PVC plastic film

- Q: How do geomembranes handle wave action?

- Geomembranes are designed to handle wave action by providing a barrier that is resistant to the forces generated by waves. They are typically made of durable materials, such as high-density polyethylene or PVC, that can withstand the impact and pressure exerted by waves. The smooth surface of geomembranes helps to reduce the frictional forces generated by the waves, allowing them to easily glide over the surface. Additionally, geomembranes are often anchored or secured in place to prevent displacement or damage caused by wave action. Overall, geomembranes are engineered to effectively handle wave action and provide reliable protection for various applications such as coastal erosion control or containment of liquids.

- Q: How to remove the film on the floor?

- (take a corner off by nail and slowly remove the whole film.) If the film is used for a long time, then the cleanser is required.

- Q: Are geomembranes resistant to hydrostatic pressure?

- Yes, geomembranes are designed to be resistant to hydrostatic pressure.

- Q: Can the mobile phone stick the tempered film

- Who suggests to paste the glass film: 1. The people who like to change the mobile phone and sale second-hand phone, because the screen is very important to the second-hand price; 2, the people who always break the phone; 3, the people who like to pursuit the new product and always wanna to try the new pridcts; 4, The people who want to get rid of the unsmooth feeling of regular film.

- Q: What products are hdpe waterproof board and HDPE geomembrane?

- hdpe waterproof board and HDPE geomembrane are anti-seepage film of high density polyethylene.

- Q: What are the principles of diaphragm pump?

- Reciprocating diaphragm pump is powered by electromotor, driving bent axle, connecting rod and crosshead through coupler and speed reducer to transfer rotational motion into rectilinear motion, and driving piston in reciprocating motion, transferring hydraulic pressure into hydraulic cylinder diaphragm chamber through hydraulic pipe. When piston move backward, it will absorb the diaphragm in diaphragm chamber backward by means of oil medium. Open feed valve with the help of pulp inlet intrusion (feeding) pressure, and then absorb pulp to fill diaphragm chamber. When piston moves forward, it will push the diaphragm in diaphragm chamber forward by means of oil medium. Start bleeder valve to transport pulp to outlet pipe. The reciprocating motion of piston makes the start and stop of suction anddrainage valve in pump head assembly reach the purpose of conveying medium.

- Q: How to distinguish 3m film true and false?

- Naked eyes are not able to distinguish. It mainly depends on the credibility and reputation of the business to determine whether it can have dealership of 3M. 3M automotive film produced the first thermal insulation and explosion-proof membrane in the world in 1966. It is a producer that can individually produce explosion-proof heat insulation membrane from beginning to end and currently owns multiterm patented technologies of thermal insulation and explosion-proof membrane, owns multiterm global patent in the field of optical technology, produces more than 3 kinds of new heat insulation membrane products per year on average. Each patented technology bestows heat-insulating film to different special function, such as 3M smart heat insulation membrane technology of professional anti-eavesdrop.

- Q: Can geomembranes be used for erosion control in rivers and lakes?

- Yes, geomembranes can be used for erosion control in rivers and lakes. These impermeable liners are designed to prevent the loss of soil particles and the erosion of underlying materials by creating a barrier between the water and the underlying soil. They are commonly used in various erosion control applications, such as lining riverbanks, lake shores, and reservoirs, to protect against erosion caused by water flow and wave action.

Send your message to us

Reinforced Polypropylene Geomembrane - 0.15-3mm HDPE/LDPE Geomembrane Price for Liner Piscine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords