High Quality Galvanized Iron Steel Bar 30x30 50x50 60x60 Zinc Coated Angle Ceiling Grid Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

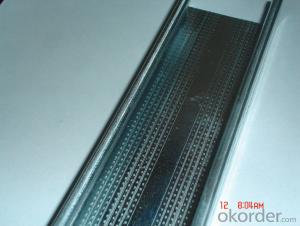

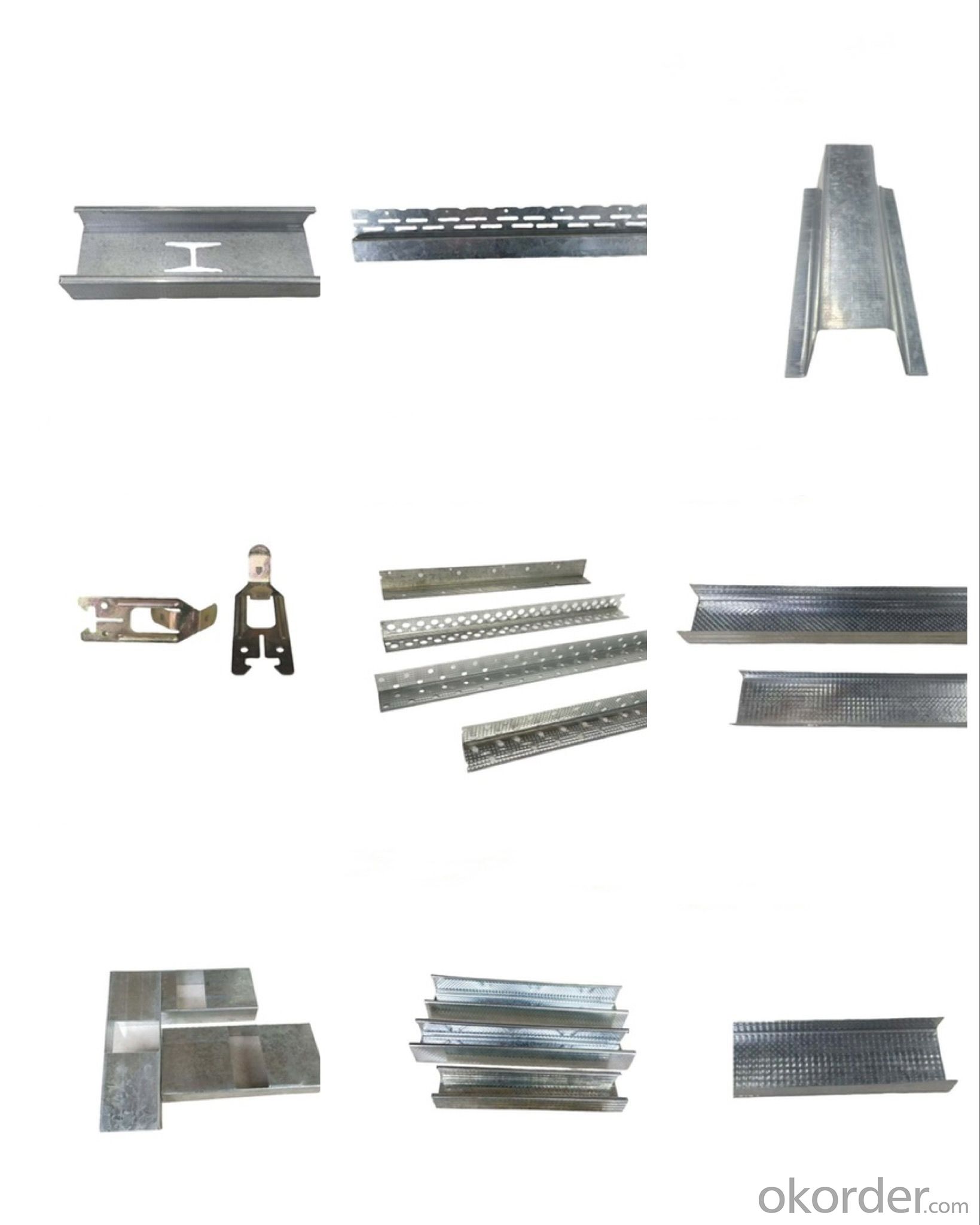

Galvanized suspended metal profile is made of hot galvanized steel, including Ceiling Channel, Metal Carrier, Omega Furring Channel, Wall Angle & fitting accessories. Galvanized ceiling channel has light weight, high strength, fire resistance and noise reduction features. It can be installed with gypsum plasterboard, calcium silicate boards, and other decorative materials.ItemCeiling Steel Profile.

company introduction

a professional metal mesh manufacturer with many years of experience, is a company specializing in the production, sales and service of metal mesh, corner guard, block steel mesh and other construction-related products. Our state-of-the-art manufacturing equipment, skilled workers, high-tech automated production technology and strict quality control ensure that we can quickly produce the most cost-effective qualified products for all our customers. With deep expertise and extensive experience, our engineering and sales teams are happy to help and advise you on finding the best solution for your project. With our advanced technology and in-house production, we can constantly upgrade our products and flexibly respond to changing customer needs.

Product description

Product Name Light skeel keel

Material Galvanized Stee

Feature L/C/U/0MEGA

Package Tape

Advantage Favorable price, lightweight

Zinc 30g-275g

Installation Convenient

Size Customer's Requirment

Product packing

Container size

20GP 5.8*2.25*2.32M

40GP 11.8*2.25*2.32M

40HC 11.8*2.25*2.62M

Standard weight of container:28T(Under normal circumstances)

When the galvanized steel in the container reaches close to the specified weight, it can be loaded into other products with large volume and light weight, such as insulation materials.

FAQ

Q:What is your advantage?

A:We are manufacturer,our company has realized 70% mechanical automation, greatly reduce labors cost. We signed long term contract

with several raw materials factory, guarantee lower price & good quality.

Q: How long is your production time ?

A:10-25 working days after receiving deposit.

Q:What is the shipping way?

A:By sea to your nearest seaport.

Q:Can you product according to the sample?

A:Yes,we can produce according to customers samples or technical drawings. Products can be customized.

Q:Do you provide samples for free?

A:We can provide samples for free, but you need to pay for DHL express cost.

- Q: Will the light steel keel ceiling area is small can be no boom?

- But if there is no boom, then a long time there is danger, after all, the main force of the ceiling keel is the boom.

- Q: Why the ceiling keel

- 1, modeling should use the ceiling keel, only to facilitate the fixed gypsum board, carved panels, panels and other materials 2, can be directly used wood board primer, which is only suitable for small area ceiling keel, it acts as a keel role. Expansion: home use generally use wooden keel, tooling or large-scale ceiling is required to use light steel keel.

- Q: Toilet integrated ceiling with good or good light steel keel good

- Now the integrated ceiling is a metal keel, if the wood for a long time will be deformed (the toilet is relatively large water), in appearance is not good. Metal keel will not appear this situation, so no matter in quality or time will not be a problem, rest assured to use.

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- Light steel keel: Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on. ? Light steel keel 38 refers to the material used as keel is light steel, its cross-section and the channel is similar to the width of 38 mm series, the height of 12 mm, the thickness is not a certain value, generally depending on the force from 0.5 mm To between 1.0 mm. 38 * 12 * 0.5 38 * 12 * 0.6 38 * 12 * 0.7 38 * 12 * 0.8 38 * 12 * 1.0

- Q: Light steel keel specifications

- T-keel and L-keel there is no national standard, the manufacturers of product specifications are not the same. T-shaped keel as the main dragon keel skeleton, from the top of the keel frame and take the role of decorative panels, the general specifications 1200mm, 3000mm, as well as keel skeleton for the keel (horizontal transverse keel) at the same time with decorative panels , The keel is T-keel, relatively short, according to your side of the decorative plate side, 600 × 600 gypsum board ceiling with the keel on the long 600mm. L-type keel for the side keel, mainly from the ceiling skeleton and indoor walls or the connection of the wall, but also part of the decorative panels, generally 3000mm a.

- Q: Do steel keel ceiling, need to use white latex?

- If the ceiling with light steel keel, then white latex is used to stick gypsum board between the suture, not add putty but kraft paper Kazakhstan.

- Q: The difference between light steel keel ceiling and macadam ceiling

- 1. Light steel keel ceiling for large area ceiling, fire, anti-corrosion performance is better. And more environmentally friendly. 2. Daxin board ceiling for local modeling ceiling, for example, you have to do a round on top of a circular arc. According to your top design, sometimes light steel keel and big core board has.

- Q: Light steel keel gypsum board partition and ceiling how much money per square meter

- Will the landlord where the. The price area is somewhat different.

- Q: Wood keel and light steel keel were used for where?

- Light steel keel main use in a large area of the ceiling, the general home decoration in addition to kitchen and steel is used outside the light keel are used wood keel. Be sure to pay attention to full brush fire retardant coating.

- Q: Light steel keel how to do secondary ceiling

- From top to bottom to do, the highest point to do a good job, and then do the following level, and the wood is interspersed with the construction is good, if not let it only play two rows of hanging bars

Send your message to us

High Quality Galvanized Iron Steel Bar 30x30 50x50 60x60 Zinc Coated Angle Ceiling Grid Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products