Wafer Butterfly Valve with PTFE Seat High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 pc

- Supply Capability:

- 600 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Adoptive Standard for High performance DI wafer butterfly valve with PTFE seat:

1.Valve Design:MSS SP-67/Class 150 for Casting steel,API609+ANSI B16.1 for DI/CI

2.Flange:ANSI B 16.1 Class 125,DIN250 1 PN10/16,BS4504 PN10/16

3.Face to face:BS EN558-1,the length in BS EN558-1 is the same in DIN3202/API609/MSS SP-67:2002

4.Pressure test conform to API598

2. Features of High performance CI/DI wafer butterfly valve with PTFE seat:

(1) Small in size and light in weight and maintenance. It can be mounted wherever needed.

(2) Simple, compact structure, quick 90 degree on-off operation.

(3) Disc has two-way bearing, perfect seal, without leakage under the pressure test.

(4) Flow curve tending to straight-line. Excellent regulation performance.

(5) Various kinds of materials, applicable to different medium.

(6) Strong wash and brush resistance and can fit to bad working condition.

(7) Center plate structure, small torque of open and close.

(8) Long service life. Standing the test of ten thousands opening and closing operation.

(9) Can be used in cutting off and regulation medium.

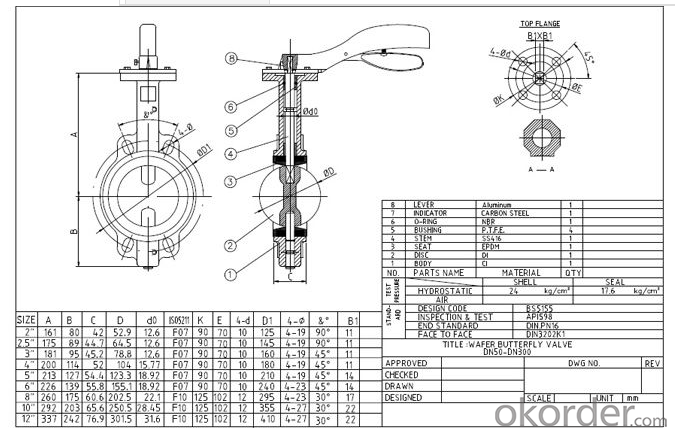

3. Images of DI wafer butterfly valve

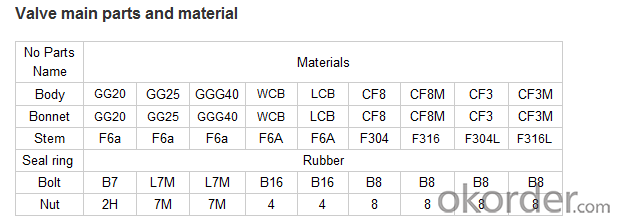

4. Specificationes of DI wafer butterfly valve

5. FAQ

1. What is manual wafer butterfly valve?

Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: The difference between butterfly valve d71x_10s and d341s-10

- Before distinguishing between the two, you must first read the identification of the valve type:D stands for butterfly valves,3 means that the worm gear is connected and the drive does not indicate the handle7 and 4 indicate pipe to clamp connection, pipe flange connection, respectively1 means single eccentric, that is, the stem is not in the center of the butterfly plateThe former S indicates the material name of the valve body - plastic, X means sealing and the lining material is rubberThe latter S indicates the sealing lining material code ---- plastic, and the valve body is cast iron.10 means stress.

- Q: How much is the Honeywell butterfly DN300?

- Find the agent or find a reliable valve plant a lot of foreign brands are in Chinese OEM so find a reliable factory is relatively good service to keep up

- Q: How can one - way sealed butterfly valves and two-way sealed butterfly valves be distinguished?

- Two way hard sealing butterfly valve:Two way butterfly valve on the valve body usually does not indicate the direction of the media arrow sign, in the design of two-way sealing butterfly valve stem force is greater than one-way butterfly valve stem. The same diameter, pressure butterfly valve, two-way sealing butterfly valve rod diameter than one-way sealing butterfly valve stem diameter. At the time of installation, the butterfly plate can face or back the direction of the medium, without considering the flow direction of the medium.

- Q: What is the electric butterfly valve? Please, great God!

- Therefore, this butterfly valve is the best matching product of automatic fire sprinkler system. The structure characteristics and working principle: the top design electrical device the butterfly valve of the worm and the worm gear driving device, and with the stem straight connecting transmission. In the closed precision electromechanical device, opening mechanical instructions and imported electrical components and parts with rust proof valve.

- Q: The flow ratio of area and maximum flow area of the valve is? If it refers to the opening of the valve rotation angle? Butterfly linear closure refers to the butterfly valve at constant angular velocity close? When the change trend of flow is what? These valves problem bothering me for a long time,

- Butterfly valve is fully open to fully closed is usually less than 90 degrees, the opening refers to the butterfly plate rotation angle;Linear closing should be the locator is linear, if the potentiometer is 0-10 euro, corresponding to 0-90 degrees, 500 Europe, opening 45 degrees;

- Q: How to use the fire butterfly valve properly?

- Clamp and groove type and signal butterfly valve, the first two have what requirements of installation, the operating handle can rotate to open and close the valve installation, signal wiring, mouth down, to prevent water and caused a short circuit three line grounding and alarm line for leakage protection and monitoring of the valve open or closed, general are in line with the alarm valve or flow indicator matched with water, indicating the spacing of not less than 300mm, no other special requirements

- Q: CAD drawing of butterfly valve

- Your question is very international. Ha-haThis method of painting is not clear in one or two words.First you'll know the map, then you'll use CAD, so the two will add up.Guess you will.

- Q: What is the meaning of American Standard butterfly valve B series

- American Standard flange connection is divided into A, B series. A series for normal flanges, B series for compact flanges. 24 "to no AB series, flange standards for B16.5, 24" above B16.47.

- Q: What kind of butterfly valve is sd342x?

- Sd342x: two-way double eccentric soft sealing butterfly valveS: two way pressureD: butterfly valve3: turbine operation4: flange connection2: double eccentricX: rubber sealProbably the shape is not so good in appearance,Double eccentric mostly elastic sealThree eccentric is multi-layer sealHope to be of help to youOpened valve Co., Ltd. on the production of butterfly valve

- Q: Butterfly valve is generally used in what position?

- It can also be used for switch control of low pressure pipeline medium.

Send your message to us

Wafer Butterfly Valve with PTFE Seat High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 pc

- Supply Capability:

- 600 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords