Butterfly Valve DN250 BS5163 for Wholesales Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

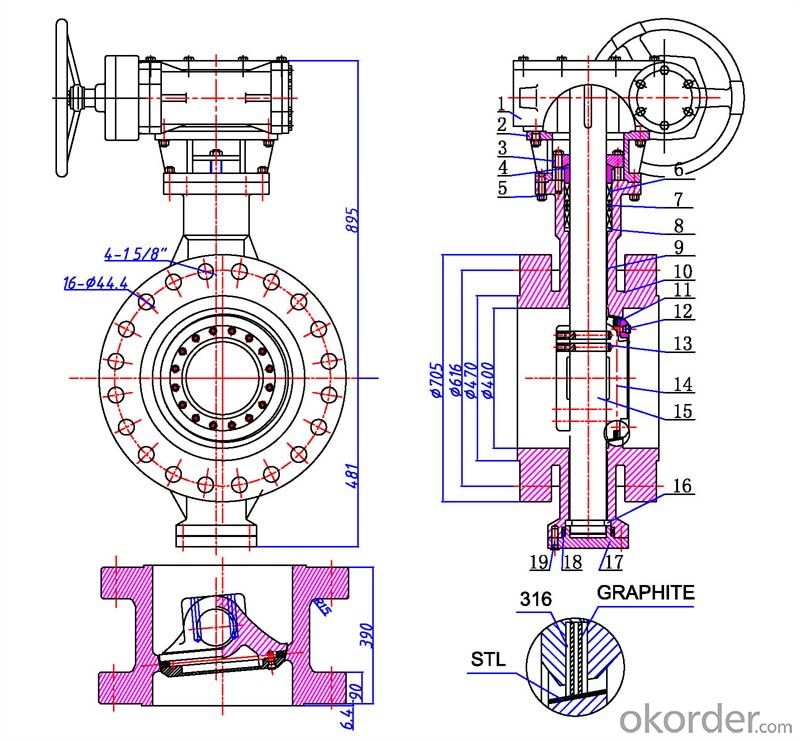

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Does the wet alarm valve group need to install the signal butterfly valve?

- Wet alarm valve at the front of the signal butterfly valve with the main floor of the main role of the butterfly valve, first, maintenance, and two is the prompt sprinkler system, there is a signal butterfly valve closed, should be repaired as soon as possible.

- Q: Why anti condensation of aluminum alloy anti condensation butterfly valve?

- Anti condensation butterfly valve multi-level unique progressive contact seat design, the valve plate in close contact in the process of gradually seat, ensure good sealing performance while reducing unnecessary torque, and the butterfly plate of stainless steel and the inner parts, thereby prolonging the service life of the valve seat, has strong rust and corrosion function. Torque reduction enables the drive to be lightweight and miniaturized. Unique stem seal prevents fluid leakage.

- Q: How do you explain A in butterfly valve D37A1?

- Represents a seal or lining material symbol.Said sealing ring or lining material with the Chinese phonetic alphabet: B Babbitts D nitrided steel, acid resistant stainless steel H, J L Aluminum Alloy, hard rubber, nylon NL, P leather, SA PTFE, SC PVC, SD bakelite, T copper, TC enamel, X rubber, Y hard alloy

- Q: What are single eccentric and double eccentric in butterfly valves? What's the difference, please explain in detail?

- Three eccentric butterfly valve: to high temperature, must use hard seal, but the leakage is large; to zero leakage, must use soft sealing, but not high temperature. In order to overcome the double eccentric butterfly valve this contradiction, and the butterfly valve for third times eccentric. The so-called third eccentric, that is, the shape of the sealing pair is not a positive cone, but rather oblique cone.Variable eccentric butterfly valve: variable eccentric butterfly valve is unique in that the valve stem axis installation disc is a three shaft type structure, the three stem shaft two concentric shafts, while the center section of the shaft center line and both ends of a center axis deviation distance, the installation disc in the middle section of the shaft. The eccentric structure makes the disc become double eccentric at full open position, and becomes eccentric when the disc rotates to the closed position. Due to the action of the eccentric shaft, near the close, the butterfly plate sealed to the seat by moving a distance within the cone, the butterfly plate and the valve seat sealing surface to achieve consistent and reliable sealing performance.

- Q: How do hydraulic butterfly valves work?

- The valve hydraulic device is mounted on the valve drive shaft. The driving shaft of the valve is fixed with a transmission spline, and the crank (with an outer spline) is sleeved on the driving shaft. When the hydraulic system works normally, through the gear sleeve, the transmission spline is connected with the crank. Thus, the hydraulic cylinder drives the crank, and the spline on the crank passes the torque to the transmission spline by means of a gear sleeve. Because the driving spline is fixed on the driving shaft, the driving shaft rotates and drives the valve plate to start and close. Sorry, the picture doesn't come up

- Q: Butterfly valve model D373F-16C, ask God answers

- D butterfly valve, 3 turbo rotating, 7 pairs clip type, 3 eccentric F PTFE seal, 16 nominal pressure 1.6MPA, C valve body material, carbon steel

- Q: Gate valve, butterfly valve and so on can do the valve so that?

- Do a lot of use valve and butterfly valve, pneumatic / hydraulic, or electric device, automatic control valve, adjust its switch angle, so as to achieve the purpose of regulation. For example, in the factory, in order to ensure the top pressure, then the pressure regulating valve, the valve is automatically adjusted by a butterfly valve! And there is also pressure regulator, pressure regulator valve series is used independently. Of course the more, is mainly used to adjust the flow!

- Q: Types of butterfly valves

- Butterfly valve structure categories: central to clip butterfly valve, central flange butterfly valve, single eccentric butterfly valve, double eccentric butterfly valve, eccentric butterfly valve, soft sealing butterfly valve, hard sealing butterfly valveButterfly drive categories: handle, worm gear, electric, pneumatic, electromagnetic, electromagnetic, hydraulic, electro hydraulic, hydraulic, hydraulic, pneumatic

- Q: what are the step i need to do so i can change the valve seals my truck has been smoky.,,, any websites i want todo it myself... 1989 chevy silverado 2500 350 engine 5.7L

- bypass purchase a Haynes or Chilton handbook. they're the suitable components of education for this undertaking. If i attempted to element this education here it might take all night to describe all of it.

- Q: butterfly valves d7a1x5

- D- valve type (butterfly valve), 7- connection mode (to clamp), A- valve shape mode (A), 1- structure form (vertical plate), X5- valve seat sealant species (Ding Qing, NBR)

Send your message to us

Butterfly Valve DN250 BS5163 for Wholesales Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches