High Quality Acid Resistant Fused Cast AZS Brick for Glass Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1222222 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

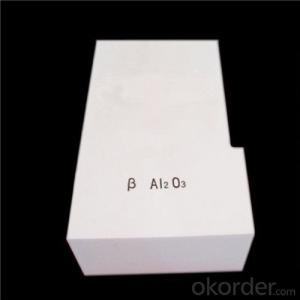

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | SIO2 |

| SiO2 Content (%): | ≥ 65 | Al2O3 Content (%): | - | MgO Content (%): | - |

| CaO Content (%): | - | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | - |

| SiC Content (%): | - | Model Number: | Acid-proof brick | Brand Name: | RS |

| Brand: | Rongsheng | Bulk density(g/cm3): | 1.0 | Cold Crushing Strength(Mpa) ≥: | 10 |

| Thermal Conductivity(W/m.k) ≤: | 0.45 | Water Absorption(%) ≤: | 15 | Acid-proof rate(%) ≤: | 98 |

| Service temperature( ℃) ≤: | 1000 | Price: | Factory Outlet | OEM: | Yes |

| Size: | You decide |

Packaging & Delivery

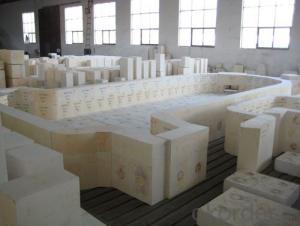

| Packaging Details: | Bricks are packed on wooden pallet and then polyethylene film is placed over it, finally the package is tied up with steel strips. |

| Delivery Detail: | 7 days after receiving deposit or as per requirements |

Acid-resistant Chimney Brick For The Lining Of Furnace

Product Description

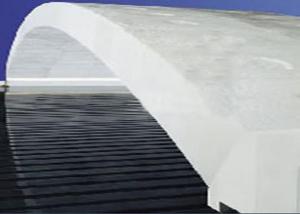

Application For Acid-resistant Chimney Brick:

Acid resistant brick widely used for the flue,chimney lining of thermal power plant, coke oven roof, cold coke tower, storage tank and sieve focal system slip focal slot lining,Anticorrosive device, Acid resistance pool, Acid resistance ground, Wear-resisting ground , etc for thermal electric power, coking, chemical industry.

Feature For Acid-resistant Chimney Brick:

1. Good acid resistant.

2. High strength and Wear resistance.

3. Low water absorption and low apparent porosity.

4. Good eroding proofing and impact resistance.

5. High temperature resistant.

6.Good thermal shock resistance.

7. High mechanical strength.

Technical Index For Acid-resistant Chimney Brick :

| Special acid-proof brick | Lightweight acid-proof brick | |

| Index | ||

| SiO2(%) ≥ | 65 | 65 |

| Bulk Density(g/m³) | 1.6-1.8 | 1.0-1.3 |

| Cold Crushing Strength(Mpa) ≥ | 15 | 10 |

| Thermal Conductivity(W/m.k) ≤ | 0.65 | 0.45 |

| Water Absorption(%) ≤ | 15 | working face 5 |

| Acid-proof rate(%) ≤ | 98 | 97 |

| Service temperature( ℃) ≤ | 1000 | 1000 |

- Q: What is acid proof brick

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, made by high temperature oxidation corrosion resistant materials, resistant to high pH, low water absorption, is not easy to be oxidized at room temperature, the media can not easily be pollution performance, except hydrofluoric acid and hot phosphoric acid, the temperature of chlorine saline, hydrochloric acid, sulfuric acid and nitric acid and at room temperature in any concentration of alkali, corrosion resistance are excellent.

- Q: Acid proof brick, acid resistant porcelain in the paste process with no seam

- As the base layer, bonding layer and acid brick itself thermal expansion, cold shrinkage coefficient is very different, in 1-2 years of hot and cold tension failure, too dense paving easily lead to acid brick swelling, fracture and other issues

- Q: Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred. If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

- Q: Is there a construction picture for the acid proof brick in the pickle pond?

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q: How can acid proof cement be used?

- In the use of acid resistant cement, it is necessary to add hardener sodium fluosilicate, it will be mixed with acid resistant cement evenly; preferably 2 times screening.

- Q: Is it necessary to use sulphate resisting cement in alkaline areas?

- The sulfate resisting silica cement is divided into two categories: medium sulfate resistant Portland cement and high sulfate resistant Portland cement. A suitable cementitious material with resistance to moderate concentration of sulfate ion is prepared by adding proper amount of gypsum in the proper proportion of Portland cement clinker, which is called medium sulfate resisting portland cement. Middle sulfur resistant cement. Code P & MSR. A cementitious material with high resistance to sulfate ion corrosion is prepared by adding proper amount of gypsum into the clinker of proper proportion of Portland cement clinker, which is called high sulfate silica cement. High sulfur resistant cement.

- Q: What brand does acidproof ceramic tile ten big famous brands have?

- What are the brand in the introduction of acid resistant ceramic ten brand-name before, we first introduce a black & decoration industry, Nalute diamond millstone. Now the decoration can not tile, cement and stone can be used to build silicon instead of diamond millstone tile, cement and building stone stone diamond silicon seamless and cast-in-situ seamless, no bacteria, diamond stone can release negative oxygen ions, make people relaxed and happy. Diamond millstone seamless cement and building stone by three silicon material composition: Nalute special cement mortar, defend a concrete seal curing agent and defend the wire concrete seal curing agent.

- Q: 98% acid tank cofferdam can use acid resistant brick?

- The operation temperature of some hot oil pumps in hydrogenation unit is higher, which is higher than the spontaneous ignition point of oil products. If there is leakage, it is prone to fire accidents. Therefore, the operation should pay attention to the operation of hot oil pump, pay attention to pump body, sealing and so on whether there is leakage, if leakage should be dealt with immediately.

- Q: What is acid proof tile, acidproof ceramic tile brand introduction?

- Among them, the detection of acidity and alkalinity is one of them. The state has relevant standards.Among them, the inspection standard of glazed tiles is different from that of polished tiles.

- Q: Acid resistant brick lining, engineering scaffolding, how to take?

- Material preparation: the anti-corrosion materials used in this project are stored in the appropriate warehouse (site), and the incoming materials are tested to comply with the requirements of the HGJ229-91 specification. Equipment preparation: cutting machine, mixer, grinder, trolley, cement plate, rope

Send your message to us

High Quality Acid Resistant Fused Cast AZS Brick for Glass Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1222222 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords