Acid Resistant Brick for Petroleum Corrosion-Resisting Liners

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Acid Resistance Brick

CMAX acid resistance brick is specially used as lining in reaction tower of chemical plants, fertilizer factories and sulfuric acid industries or inside the corrosion-resistance pool and ditch.

Feature of Acid Resistance Brick

Strong acid and alkali resistance

Size available as customer’s requirement

Application of Acid Resistance Brick

Acid Resistance Brick is widely used in corrosion-resisting liner of petroleum, chemical industry, chemical fertilizer, food, chemical fiber, laboratory, pharmacy, papermaking, generate electricity, smelt, electroplating room, and the inner corrosion-resisting lining of tower, pool, pot, tank, etc. It is also used for sewage conduit and open-air floor.

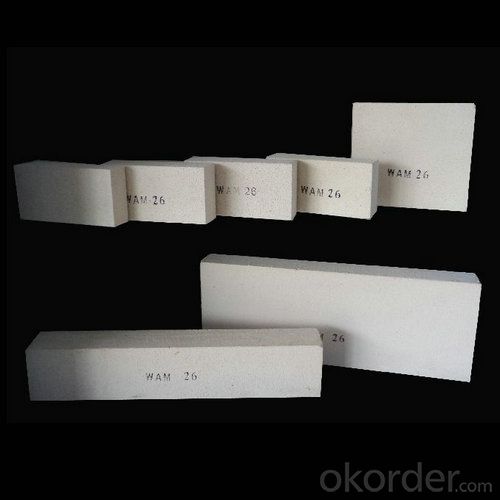

Images of Acid Resistance Brick

Technical Data of Acid Resistance Brick

ACID RESISTANCE BRICK

Chemical Composition (%)

SiO2 68

Al2O3 25

Fe2O3 ≤2

CaO+MgO ≤2

Na2O+K2O ≤3

Bulk Density (g/cm3) ≥2.2

Water Content (%) 3-5

Cold Crushing Strength (Mpa) 85

Bending Strength (Mpa) ≥58.8

Acid Resistance (%) ≥99.8

Under Thermal Shock Resistance Testing No cracking

Water-absorptivity Average A 0.2%≤A≤0.5%

FAQ of Acid Resistance Brick

1. Who We Are?

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

2. What We Can Do?

We can supply ALL KINDS OF REFRACTORIES and CERAMIC FIBER PRODUCTS in high quality and competitive price.

3. Who Our Customers Are

MORGAN THERMAL CERAMICS

ALLIED MINERAL

UNIFRAX

- Q: What is acid proof brick

- The main component of acid resistant ceramic tile is silica, which forms a large amount of andalusite under high temperature calcination, which is a kind of material with high acid resistance. The acid proof brick structure, low water absorption, so at room temperature are resistant to alkaline medium at any concentration, but not resistant to high temperature molten alkali. Acid resisting brick contains more than 70% silicon dioxide, and is made by sintering. It is used in acid chemical ditch, acid well, acid storage storehouse and acid loaded big impact ground.

- Q: Acid proof brick, acid resistant porcelain in the paste process with no seam

- As the base layer, bonding layer and acid brick itself thermal expansion, cold shrinkage coefficient is very different, in 1-2 years of hot and cold tension failure, too dense paving easily lead to acid brick swelling, fracture and other issues

- Q: Does the chimney have high acid resistance?

- The acid resistant bricks used for chimney are usually made of custom-made trapezoidal acid proof bricks, and the physical and chemical indexes of acid resistant bricks need to be confirmed according to the chimney's actual emission. At this point, you can consult our kerei refractories.

- Q: Is acid proof brick alkali resistant?

- Absolutely neutral materials do not react with acids, nor react with alkalis, and do not react at higher pressures and temperatures. Of course, this condition is not endless.

- Q: Is there a construction picture for the acid proof brick in the pickle pond?

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q: Consult: water treatment room anticorrosive usable granite and acid resisting brick, these two kinds of material what?

- You can look at RZG/, the proportion of Rizhao garnet, high hardness, good toughness, wear resistance, acid and alkali resistance, flushing, moderate porosity, in the field of sewage treatment is widely used as a high density filter (heavy medium filter).

- Q: Is it necessary to use sulphate resisting cement in alkaline areas?

- The sulfate resisting silica cement is divided into two categories: medium sulfate resistant Portland cement and high sulfate resistant Portland cement. A suitable cementitious material with resistance to moderate concentration of sulfate ion is prepared by adding proper amount of gypsum in the proper proportion of Portland cement clinker, which is called medium sulfate resisting portland cement. Middle sulfur resistant cement. Code P & MSR. A cementitious material with high resistance to sulfate ion corrosion is prepared by adding proper amount of gypsum into the clinker of proper proportion of Portland cement clinker, which is called high sulfate silica cement. High sulfur resistant cement.

- Q: Which acid proof tile factory is reliable in quality?

- We all know that the main component of acid resistant ceramic which is silica, liangdun acid resistant ceramic material is used by Shanxi local quartz stone, containing a large number of silicon content, acid resistant tiles can thus produced corrosion.

- Q: What brand does acidproof ceramic tile ten big famous brands have?

- Now let's introduce in detail of acid resistant ceramic ten brand-name what brand, in fact the ten major brands of ceramic tile manufacturers have to choose acidproof tile, tile acid, these ten brands of ceramic tile manufacturers to be sure, but the ten tile brand ranking of two, you can go to compare, look at the two ten famous brand rankings have what different tiles.

- Q: How much is one square meter of acidproof tile?

- Acid resistant brick: resistance to pressure, corrosion resistance, easy to clean, acid and alkali; acid resistant tile prices generally around 40 yuan a square meter!

Send your message to us

Acid Resistant Brick for Petroleum Corrosion-Resisting Liners

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords