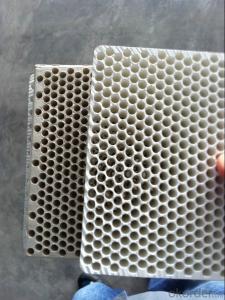

High Purity Alumina Ceramic Tube Used in Industry

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. Alumina has a high melting point, high hardness, although mechanical strength is reduced at temperatures above 1000 C. Due to the relatively large coefficient of thermal expansion, thermal shock resistance is reduced.

Alumina is also an electrically insulating material, with a high electrical resistivity, increasing with purity. Good chemical stability of alumina leads to high corrosion resistance as well. It is insoluble in water and only slightly soluble in strong acid and alkaline solutions. Testing has shown that the low chemical solubility of alumina ceramics components makes them highly resistant to chemical corrosion. This is what makes high purity alumina the material of choice for components in a wide range of industrial applications.

Ceramic tubes are used when electrical insulation is necessary in high heat applications. This makes them useful for supporting electric heating elements in ovens, heaters and furnaces. Ceramics hold their shape and size under pressure. This is important in switching applications where the ceramic is used to open and close electrical contacts in a thermostat or pressure switch. Ceramic parts are very abrasion resistant and offer long life in applications where other materials would wear out quickly.

Main Physical Properties:

1. Good electrical insulation

2. High mechanical strength

3. Excellent wear resistance

4. Excellent corrosion resistance

5. Low dielectric constant

Main Applications:

1. Pump seals and other components

2. Wear resistant inserts

3. Insulating washers or bushings

4. Semiconductor components

5. Aerospace components

6. Automotive sensors

7. Electrical or electronic insulators

Data Sheet

Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

Color | - | white | ivory | white | gray | white | white |

Density | g/cm³ | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

Flexural Strength | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

Compressive Strength | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

Thermal Conductivity | W/(m•K) | 18-25 | 30 | 2.2 | 25 | 20 | 1.70 |

Thermal shock resistance | ΔT(C°) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

Max. Working Temperature | C° | 1500 | 1700 | 850 | 1200 | 960 | 800 |

Volume Resistivity | Ω . cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

Dielectric Constant | - | 9.50 | 9.80 | 26 | 8.20 | 4.08 | 6.02 |

Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

FAQ

We have organized several common questions for our clients, may help you sincerely:

--------What is the application of Ceramic Tubes?

1. Pump seals and other components

2. Wear resistant inserts

3. Insulating washers or bushings

4. Semiconductor components

5. Aerospace components

6. Automotive sensors

----------What advantages of Ceramic Tubes?

1. Good electrical insulation

2. High mechanical strength

3. Excellent wear resistance

4. Excellent corrosion resistance

5. Low dielectric constant

- Q: What brand of ceramic tableware is good?

- Direct home network selection ah, all brands are home porcelain online, a variety of international brands of household ceramics.

- Q: I‘m planning on straightening my hair and I already have ionic flat iron at home. Is it good enough or should i get a ceramic one? What‘s the main difference?

- Ceramic Vs Ionic Flat Iron

- Q: ive always used ceramic but never tourmaline because i thought it was bad for your hair?what is better ? should i look for a straightener that?is only ceramic ? or only tourmaline ? or both ?

- Tourmaline is better and is less damaging to your hair. If you get an iron then make sure it at least has ceramic plates, even if they are ceramic coated. Anything below ceramic will damage your hair. Ceramic used to be the highest grade iron several years ago, but not tourmaline is the best.

- Q: How do you wash the ceramic knife in color?

- Generally speaking, ceramic knives can not be cleaned because they are dyed with color

- Q: i‘m looking for a flat iron that isn‘t too expensive, and can also curl and flip hair. ceramic flat irons are a lot more expensive. what is the difference? is it worth it to pay more for a ceramic flat iron? which brands do you recommend?

- My check advtrac light remains on all the time. It was not on and I took my Explorerto the Dealer for Service (my service light came on) so they serviced the car and reset the light to turn off. When I left the Dealership my Advtrac light came on and has stayed on. The Dealer says it s coincidence and it seems weird and they want $100.00 to check it. I know how important the system is so I want to be safe. Other than a Dealer who should I get to diagnose the problem and repair it? The Ford Dealer Repair Service makes me think I need to find another Repair Center. Any Suggestions?

- Q: I have a 2005 Lincoln Town Car and the rotors shimmy when applying the brakes, so I‘m going to change the rotors and was wondering which pads would be the best, semi-metalic or ceramic.

- Ceramic pads create a lot of heat and can cause rotor warping in addition to requiring a bit more force applied to the brake pedal. Ventilated rotors are a necessity. I personally would go with the semi-metallic pads.

- Q: Im So sick of Carpet! its Smelly , DUSTY as Hell and gross when you spillFor me anyways I here Ceramic is easy to maintainwhat do you think ?.thanks for input Athensooo

- When we had our home built we did NOT want carpeting anywhere in it. So, we have solid oak plank wood flooring, (marred on purpose prior to sealing because we have (8) dogs three boys, so the marring hides the things they can do to it) everywhere but the kitchen baths. The kitchen has stone tiles the baths all have ceramic tile. I LOVE it!!! If it is installed properly sealed properly it is VERY easy to care for. I think you will be very happy with it as your choice of flooring. Everyone always says that wood floors or tile floors are cold. Well YEAH!!! But they look cleaner, classic last soooo much better than carpeting. Besides, that's what slippers are for!!!!! We live in Alaska I cannot even imagine what carpeting would look like after even a few months. YUK!!!!!! We have a mud room people know to take their shoes off before comming into the house, because you DO have to take care of even sealed tile, stone or hard wood. I also do not believe people replace it when it looks dated. I don't feel it will ever look dated, unlike carpeting that changes IN colors, textures, etc. every year or so.

- Q: which is better? suggestible brands???

- Titanium Hair Straighteners

- Q: What's the difference between ion perm and ceramic perm?

- Ion perm suitable for hot straight hair, ceramic perm, suitable for hot hair. There are many kinds of ion perm, water ions, cations, swimming ions, negative ions, etc., it is difficult to choose for a while. But its general procedures are the same, divided into shampoo, softening, straightening and so on.Now perm is divided into two categories: cold and hot. Is the general meaning of the perm perm, perm moisturizing gel to play after wet when it is rolled, dry when the volume is not good, no hard hit something after the hair elastic. Hot now, sub ion hot, ceramic hot, digital hot and so on. The first softening in the thick stick. The difference between this perm is that it doesn't roll when wet, but when it's dry, it rolls better, and the hair is soft and elastic. Now a lot of pushing digital hot digital hot machine, because the price is not high, it is easy, but bad if the digital hot hot hot and cold, also want to make something moisturizing, if made such an effect, as do the perm, perm to lower the price. But the heat is not a panacea, some hair is going to take to do a perm.

- Q: i know stainless stell headers are good, but cant remember if ceramic is a cheap quality

- Usually ceramic coated headers are the most efficient, the ceramic coating keeps the heat inside the header, maintaining exhaust velocity and thereby the header efficiency. This is why some race cars have wrapped headers.

Send your message to us

High Purity Alumina Ceramic Tube Used in Industry

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords