Aluminum Flexible Graphite Sheet/Panel High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100Ton kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

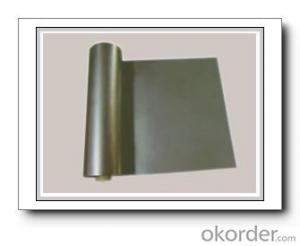

1.Structure of Graphite Sheet Description

Flexible graphite sheet is made from the high quality large flake graphite by chemical treatment, expanding while high temperature and rolling for many times.

2.Main Features of the Graphite Sheet

Main usage: to make graphite belts, fillings, sealing, gaskets, reinforced sheet, cylinder gasket, fuel cell, conducting strip, heat conduct fin, cushion collar, etc. Operating temperature: -200~~650℃(in air) -200~~3000℃(in non-oxidized meduim).

3. Specification

Tolerance of Density g/cm³ | ±5% |

Tolerance of Thickness mm | ±3% |

Carbon content % | 95~99.9% |

Tensile % | 4~10 |

Compressibility % | 45%min |

Recovery % | 11%min |

Sulphur content ppm | 200%min |

Chloride content ppm | 37max |

4.FAQ of Graphite Sheet

Q :What knid of payment terms can your company accept?

A: We can accept 30% prepayment, 70% payment before shippment

5.

- Q: As a mechanical automation's engineer that knows little about AC units I would guess sense you cant solder aluminium that you epoxy it but what do I knowAs an engineer the simplest things blow over my headI can tell you the melting point of osmium and how many isatopes there are in molybdenum but tying a shoe or using a microwave oven I can't handle

- NoDue to the great difference in melting temperatures, soldering Cu onto Al is not practicalBoth materials need to melt, mix and solidify without movement to form a crystalline boundary structure that can hold together under the pressure the tubing needs to containIt might work if you could keep the molten Cu in place as the Al cooled down to the Cu melting temperature, such as repairing a crack in the bottom of an aluminum bowl where the copper can be kept in place and immobile during coolingRepairing a tube won't work because the Cu will stay molten and roll off the Al tube as it cools from its much higher temperatureYou should just replace the tube.

- Q: Is it possible to make chain mail armor from paper clips for halloween? I was thinking about connecting them until it looked like a t shirt and then soldering them together but since its made of very light aluminum would the solder work for it and would i get lead poisoning from it?

- Thank you for the wonderful descriptionI do believe I'm going to have to buy some cake mix and milk on my way home tonightI'm totally salivating right now.

- Q: If I put aluminum foil in an oxidized copper bowl with acid solution will it react to oxidize the aluminum?

- Lol noThe acid will protonate the copper though.

- Q: Are aluminum coils suitable for high-reflective applications?

- Yes, aluminum coils are suitable for high-reflective applications. Aluminum is known for its excellent reflectivity, with a reflectance ratio of around 80-90%. This makes it an ideal material for applications that require high reflectivity, such as in lighting fixtures, solar panels, and mirrors. Aluminum coils can be coated or polished to further enhance their reflective properties. Additionally, aluminum is lightweight, corrosion-resistant, and has good heat conductivity, making it a versatile choice for various high-reflective applications.

- Q: What is the relationship between the number of pinholes in aluminum foil and represents a performance

- The bag is a transparent film and opaque side film aluminum or aluminum foil, aluminum foil bag, packing bag is full of aluminum foil composite film made of opaque, its oxygen, moisture resistance, good sealing performance etc..

- Q: Ok.here's my pumpkin roll recipe.3 eggs, 1c sugar, 2/3 c pumpkin, 1t lemon juice, 3/4 c flour, 1t ginger, 1t baking powder, 2 t cinnamon, 1/2t nutmeg, 1/2t salt.Beat eggs on high for 5 minutesGradually add other ingredients and mix wellSpread into well greased 15x10x1 panTop with chopped nuts and bake 15 min 375Turn out on flour sack towel, liberally sprinkled with powered sugarRoll up with towelCoolUnroll and spread with cream cheese mixRoll and wrap in foilSo, how do I tweek this to be chocolate?!?! Thanks!!!

- it was fat, put bbq towards the end of your cooking of the chicken, some put bbq sauce for day last few minutes

- Q: Every year, a robin builds its nest on the ledge above our front doorWe've tried to take the nest down in the past, only for one to be rebuiltThis morning I had packages delivered when I opened the door, a TON of nest debris blew into my house (obviously a very big pain to clean!)We get packages delivered almost weekly, so this can't keep happeningNot sure if this makes a difference, but I can't tell if its the same robinAfter I had to step outside to get the packages below its nest, it started making a horrible noise that I didn't think robins could make I didn't get a look at its stomachLast year, people recommended to put thumbtacks down up there to stop it from coming back, but that just seems so cruel so I never didWhat can i do about this? I greatly appreciate any help!

- Hose it away every dayYou might also add a piece of sloping material like aluminum or plastic on the area where the nest isThat would make it more difficult for the nest to stay in placeYou could tack up the material or glue itYou could leave it in place forever or take it down after the nesting season ends.

- Q: last week i smoked pot using aluminum foil as the bowli barely did any, but i've been feeling really lightheaded since thenitz weird to describe it cause i can act perfectly normal, but i still feel disorientedany reasons to what is happening to me?

- Condi Rice? You print her name as if she is someone of authority? What has she done outside what you printed in your question? OK! If Condi Rice was a white woman she'd be held up as an example of how ineffective a woman can beShe's the worst Secretary of State everThe only thing she does is make George WBush look smart! And that's doing something! Thanks

- Q: How to remove the oxide layer in the aluminum foil with a chemical process?

- Generally, we adopt the method of alkali corrosion to remove the oxide layer on the surface of the aluminum foil.The purpose of alkali corrosion is removing the oxide layer on the surface of the aluminum foil. (Note: Technological process of the method is as follows: under normal temperature, 20% nitric acid; the process parameters is about 0.5 minutes. Pre-degrease--degrease--rinsing--rinsing--alkali corrosion--rinsing--rinsing--bright dipping--rinsing--rinsing--pure rinsing. The purpose of bright dipping is to remove surface residual black ash after alkali corrosion.Temperature:50-60 degrees; time:0.5-1 minutes.The purpose of degreasing is to remove grease on the surface of the aluminum foil.The process parameters is 0.5-1 minutes. You can use acid to wash it.

- Q: This question asks for a list of various sizes and grades of aluminum profiles that can be found in the market.

- <p>Aluminum profiles are available in a wide range of sizes and grades to meet different application needs. Sizes are typically categorized by series, such as 1000, 2000, 3000, 5000, 6000, and 7000, which correspond to different alloy types. Each series has various thicknesses and cross-sectional dimensions. Grades are determined by the alloy composition and temper, with common grades including 1050, 6061, 6063, and 7075. The temper indicates the hardness and strength, with 'T' followed by a number (e.g., T6 for 6061-T6). Profiles can be flat bars, angles, channels, or complex shapes and are used in construction, automotive, aerospace, and other industries.</p>

Send your message to us

Aluminum Flexible Graphite Sheet/Panel High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100Ton kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords