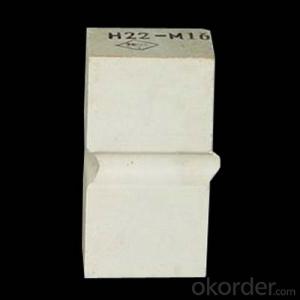

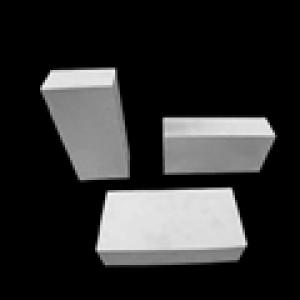

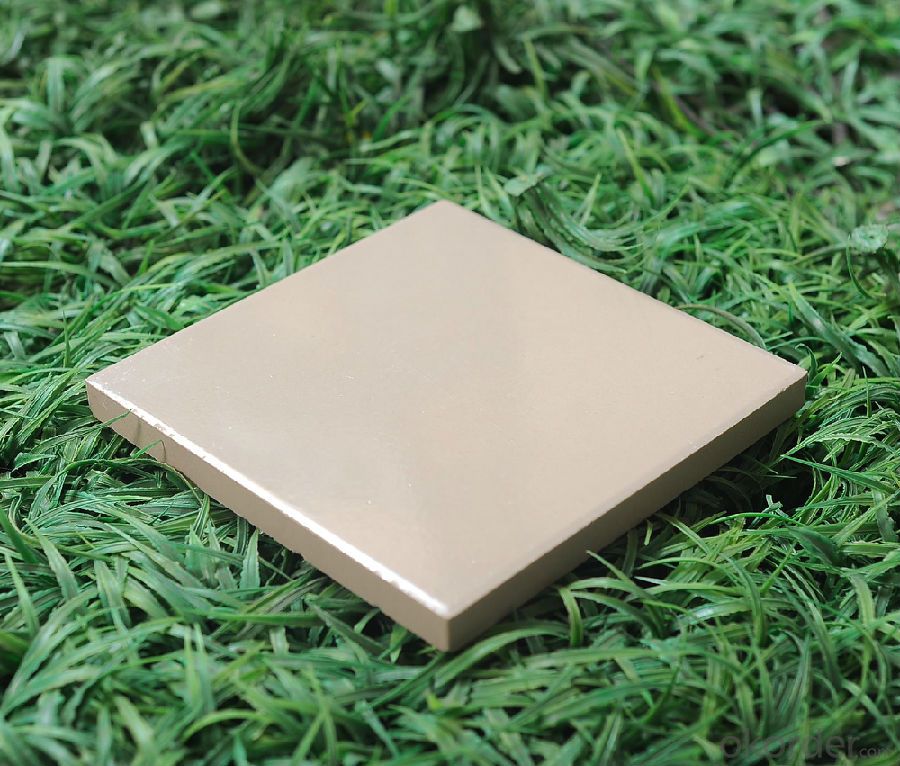

High Purity Acid Resistant Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Type: | Ceramic Plates | Application: | Ceramic Decorations |

| Material: | Alumina Ceramic | Model Number: | TW92 | Brand Name: | Tecera |

| Alumina Content (%): | ≥92 | Moh's Hardness (Mohs): | 9 | Rate of Water Absorption(%): | ≤0.01 |

| Fracture Toughness(n/mm): | 40 | Bending Strength (Mpa): | 255 | Bulk Density (g/cm3): | ≥3.63 |

Packaging & Delivery

| Packaging Details: | In carton box or PP-bag , packed in fumigated wooden pallet with net weight 20 - 25MT/20'FCL |

| Delivery Detail: | 30 days |

TW Series ® -Alumina Wear Resistant Ceramics Tile

An ISO9001&ISO14001 Certificated Company

Application:

The products, which are of wear-resistance, excellent impact-resistance, easy operation are ideal surface wear-resisting material for material transfer equipment in mining, iron & steel works, thermal & power plants, mine, etc, and can extend operating life of equipment effectively. Theoretically the life time of the alumina ceramic is about 260 times longer than that of manganese steel and 170 times longer than that of chrome steel.

Performance Index:

Products | TW92 ® | TW95 ® | TW97 ® | TW99® |

Alumina Content (%) | ≥92 | ≥95 | ≥97 | ≥99 |

Moh’s Hardness (Mohs) | 9 | 9 | 9 | 9 |

Rate of Water Absorption(%) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Fracture Toughness(n/mm) | 40 | 42 | 44 | 48 |

Bending Strength (Mpa) | 255 | 275 | 285 | 300 |

Bulk Density (g/cm3) | ≥3.63 | ≥3.68 | ≥3.73 | ≥3.83 |

Specifications:

Size(mm) | Length(mm) | Width(mm) | Thickness (mm) | Shape |

10X10 10*10 lining Facing | 10 | 10 | 1.5-10 | Mosaic/Hex.Tile |

11.55X11.55 | 11.55 | 11.55 | 3-12 | Mosaic/Hex.Tile |

12X12 | 12 | 12 | 3-12.7 | Mosaic/Hex.Tile |

17.5X17.5 | 17.5 | 17.5 | 4-10 | Mosaic/Hex.Tile

|

20X20 | 20 | 20 | 5-15 | Mosaic/Hex.Tile

|

23.7 x23.7 | 23.7 | 23.7 | 5-15 | Mosaic/Hex.Tile

|

25X25 | 25 | 25 | 5-15 | Mosaic/Hex.Tile

|

50X25 | 50 | 25 | 5-10 | Plain Tile(Without Hole) |

50X50 | 50 | 50 | 5-15 | Plain Tile(Without Hole) |

100X100 | 100 | 100 | 6.5-15 | Plain Tile(Without Hole) |

120X80 | 120 | 80 | 6-20 | Weldable Tile (With Hole) |

150X60 | 150 | 60 | 10-25 | Plain Tile(Without Hole) |

150X100 | 150 | 100 | 6-25 | Plain Tile(Without Hole) |

150X100 | 150 | 100 | 12-50 | Weldable Tile (With Hole) |

Remark: More than 2000 sizes and shapes are available upon customer requests.

Packaging: In carton box or PP-bag , packed in fumigated wooden pallet with net weight 20-25MT/20'FCL.

Key benefits:

·Excellent anti-wear and corrosion resistance.

·Longer life than that of traditional wear protection material. ·Avoid shutdown time and maximize the productivity of your plant.

- Q: How to clean the acid brick surface dirt?

- Daily cleaning of bricks can be done with detergent, soap and other cleaning.

- Q: The acid resistance is 99.4%. Is this acid resistant brick very bad?

- Do not recommend you buy the acid resistance of substandard tile, tile acid refers to the acid resistance of 99.8 according to the national standard

- Q: Does the chimney have high acid resistance?

- The acid resistant bricks used for chimney are usually made of custom-made trapezoidal acid proof bricks, and the physical and chemical indexes of acid resistant bricks need to be confirmed according to the chimney's actual emission. At this point, you can consult our kerei refractories.

- Q: What is acidproof ceramic tile?

- Ceramic tile is acid with quartz and feldspar, clay as the main raw material, acid resistant materials by high temperature firing, with acid of high, low water absorption, is not easy to be oxidized at room temperature, is not easy to be medium pollution characteristics.

- Q: How can acid proof cement be used?

- When in use should be mixed after the finished product into the container, after adding water glass solution, mixing uniformly rapidly; usually with less than one hundred kilograms of stir, each tune into the product to be used within 50 minutes.

- Q: What is acidproof brick?

- The main component of acid resistant brick is silica, and Hao Ran acid resistant bricks are made of imported raw materials and imported color materials by high temperature firing.

- Q: 98% acid tank cofferdam can use acid resistant brick?

- The hydrogenation unit has a large amount of light hydrocarbons in its memory, and if it leaks, it will cause serious accidents. Therefore, we should pay enough attention to the operation of the light hydrocarbon pump.

- Q: What is acid proof tile, acidproof ceramic tile brand introduction?

- Acid resistant tile, each tile in production, have to do product testing

- Q: Acid resistant brick lining, engineering scaffolding, how to take?

- Material preparation: the anti-corrosion materials used in this project are stored in the appropriate warehouse (site), and the incoming materials are tested to comply with the requirements of the HGJ229-91 specification. Equipment preparation: cutting machine, mixer, grinder, trolley, cement plate, rope

- Q: How much is one square meter of acidproof tile?

- Acid resistant brick: resistance to pressure, corrosion resistance, easy to clean, acid and alkali; acid resistant tile prices generally around 40 yuan a square meter!

Send your message to us

High Purity Acid Resistant Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords