Acid Resistant Alumina Ceramic Lining Brick - High Purity, Hot CE Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 pc

- Supply Capability:

- 1222222 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | SIO2 |

| SiO2 Content (%): | ≥ 65 | Al2O3 Content (%): | - | MgO Content (%): | - |

| CaO Content (%): | - | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | - |

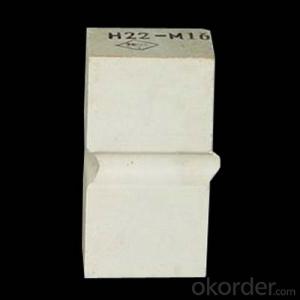

| SiC Content (%): | - | Model Number: | Acid-proof brick | Brand Name: | RS |

| Brand: | Rongsheng | Bulk density(g/cm3): | 1.0 | Cold Crushing Strength(Mpa) ≥: | 10 |

| Thermal Conductivity(W/m.k) ≤: | 0.45 | Water Absorption(%) ≤: | 15 | Acid-proof rate(%) ≤: | 98 |

| Service temperature( ℃) ≤: | 1000 | Price: | Factory Outlet | OEM: | Yes |

| Size: | You decide |

Packaging & Delivery

| Packaging Details: | Bricks are packed on wooden pallet and then polyethylene film is placed over it, finally the package is tied up with steel strips. |

| Delivery Detail: | 7 days after receiving deposit or as per requirements |

Acid-resistant Chimney Brick For The Lining Of Furnace

Product Description

Application For Acid-resistant Chimney Brick:

Acid resistant brick widely used for the flue,chimney lining of thermal power plant, coke oven roof, cold coke tower, storage tank and sieve focal system slip focal slot lining,Anticorrosive device, Acid resistance pool, Acid resistance ground, Wear-resisting ground , etc for thermal electric power, coking, chemical industry.

Feature For Acid-resistant Chimney Brick:

1. Good acid resistant.

2. High strength and Wear resistance.

3. Low water absorption and low apparent porosity.

4. Good eroding proofing and impact resistance.

5. High temperature resistant.

6.Good thermal shock resistance.

7. High mechanical strength.

Technical Index For Acid-resistant Chimney Brick :

| Special acid-proof brick | Lightweight acid-proof brick | |

| Index | ||

| SiO2(%) ≥ | 65 | 65 |

| Bulk Density(g/m³) | 1.6-1.8 | 1.0-1.3 |

| Cold Crushing Strength(Mpa) ≥ | 15 | 10 |

| Thermal Conductivity(W/m.k) ≤ | 0.65 | 0.45 |

| Water Absorption(%) ≤ | 15 | working face 5 |

| Acid-proof rate(%) ≤ | 98 | 97 |

| Service temperature( ℃) ≤ | 1000 | 1000 |

- Q: What are the standard specifications for acid resisting bricks?

- Because of the different acid and alkali environment, the acid resisting ceramic tile has different requirements on the degree of acid and alkali, so it is necessary to make the price reasonable at the time of construction,

- Q: What is anticorrosive floor tile?

- Only 30mm thick slabs in the market are not above, the most is 20mm thick slabs, the glass ceramics (that is on the market only Guanzhu, the new source, Monalisa and Baird only) are acid and alkali. Square brick (quite cheap)

- Q: Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred. If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

- Q: Is there a construction picture for the acid proof brick in the pickle pond?

- As the base layer, bonding layer and acid brick itself thermal expansion, cold shrinkage coefficient is very different, in 1-2 years of hot and cold tension failure, too dense paving easily lead to acid brick swelling, fracture and other issues

- Q: How can acid proof cement be used?

- In the use of acid resistant cement, it is necessary to add hardener sodium fluosilicate, it will be mixed with acid resistant cement evenly; preferably 2 times screening.

- Q: The difference between acid and heat resistant lightweight castables and acid resisting bricks

- Acid resistant bricks can be customized according to different environments, and resist acid and alkali brick materials of various acids and bases. And pouring materials basically uniform formula, even if a slight adjustment can not solve the strong acid, strong alkali use environment.Acid resistant bricks can be factory mass customization, the cost is slightly lower, while the casting materials need on-site construction, the cost is slightly higher.

- Q: What brand does acidproof ceramic tile ten big famous brands have?

- Now let's introduce in detail of acid resistant ceramic ten brand-name what brand, in fact the ten major brands of ceramic tile manufacturers have to choose acidproof tile, tile acid, these ten brands of ceramic tile manufacturers to be sure, but the ten tile brand ranking of two, you can go to compare, look at the two ten famous brand rankings have what different tiles.

- Q: 98% acid tank cofferdam can use acid resistant brick?

- Hydrogenation unit of hydrogen and high pressure and temperature, the system memory in the U2S and NH3, therefore, the corrosion problem of hydrogenation unit should also be emphasized, main methods to solve the corrosion problem of hydrogenation device is reasonable material, strengthen the surveillance and detection in use.

- Q: Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- Abrasive blasting is the physical cleaning of dry or suspended abrasive particles in the liquid to the surface of metal parts or products to remove corrosion products. Sand blasting can remove rust, oxide, dry dirt, molding sand or paint on metal surface.Abrasives used for dry blasting include metal sand, iron pellets, fine sand, glass, etc.. Factors such as hardness, density, particle size and shape shall be taken into account when selecting specific abrasives.Sandblasting equipment used by: no use of air sand thrown blade or impeller, pressure nozzle set rubidium: suction nozzle device, see second articles. Sand blasting cleaning is a common method of removing the corrosion products such as ferrous oxide and non-ferrous metal surface oxide

- Q: What is acid proof tile, acidproof ceramic tile brand introduction?

- Acid resistant tile, each tile in production, have to do product testing

Send your message to us

Acid Resistant Alumina Ceramic Lining Brick - High Purity, Hot CE Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 pc

- Supply Capability:

- 1222222 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords