Acid Resistant Corundum Brick for Linings of High-Temp Industrial Kilns and Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Corundum Brick

CMAX corundum bricks use compact electrosmelted corundum and alumina powder as main raw materials., shaped under high pressure after machine-blending and fired at high temperature.

Feature of Corundum Brick

Low porosity

High compressive strength

Good chemical stability

Application of Corundum Brick

Linings of high-temp industrial kilns and furnaces

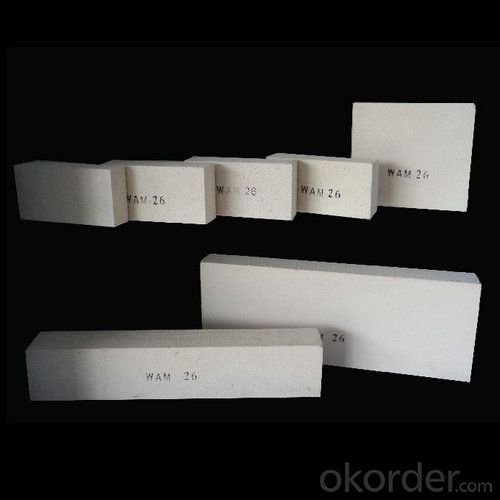

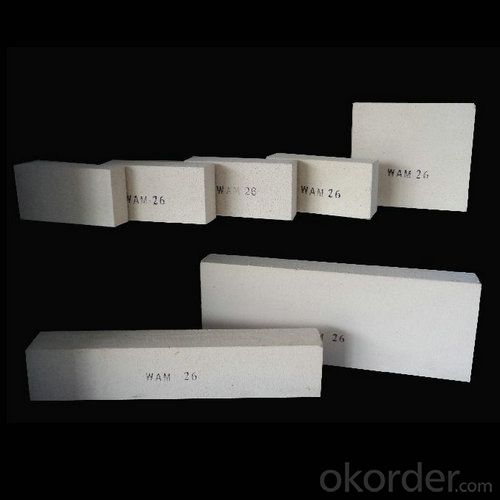

Images of Corundum Brick

Technical Data of Corundum Brick

ITEM GY-90 GY-94 GY-98

Al2O3, % ≥90 ≥94 ≥98

Fe2O3, % ≤1 ≤1 ≤0.3

Refractoriness, ℃ ≥1790 ≥1790 ≥1790

Bulk Density, g/cm3 ≥2.95 ≥3.1 ≥3.1

Apparent Porosity, % ≤16 ≤16 ≤20

Cold Crushing Strength, Mpa ≥80 ≥80 ≥60

Refractoriness Under Load (T0.6), ℃ ≥1620 ≥1650 ≥1700

Permanent Lineat Change, %

1500℃×3h,

±0.2

-

1500℃×3h,

±0.1

FAQ of Corundum Brick

1. Who We Are?

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

2. What We Can Do?

We can supply ALL KINDS OF REFRACTORIES and CERAMIC FIBER PRODUCTS in high quality and competitive price.

3. Who Our Customers Are

MORGAN THERMAL CERAMICS

ALLIED MINERAL

UNIFRAX

- Q: The acid resistance is 99.4%. Is this acid resistant brick very bad?

- Bending strength, 39.2., water absorption, 0.5-2.0., quench, hot, 100du, cycle without cracks, peeling, etc. the quality of acid resistant tiles is mainly reflected in water absorption, the lower the water absorption, the higher the acid resistance

- Q: Acid proof brick, acid resistant porcelain in the paste process with no seam

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q: What is anticorrosive floor tile?

- The above construction method is simple, and the normal paving tiles are the same. It is convenient to add 2-3mm cross micelles when leaving gaps.

- Q: Is there a construction picture for the acid proof brick in the pickle pond?

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q: How can acid proof cement be used?

- In the use of acid resistant cement, it is necessary to add hardener sodium fluosilicate, it will be mixed with acid resistant cement evenly; preferably 2 times screening.

- Q: Is it necessary to use sulphate resisting cement in alkaline areas?

- The sulfate resisting silica cement is divided into two categories: medium sulfate resistant Portland cement and high sulfate resistant Portland cement. A suitable cementitious material with resistance to moderate concentration of sulfate ion is prepared by adding proper amount of gypsum in the proper proportion of Portland cement clinker, which is called medium sulfate resisting portland cement. Middle sulfur resistant cement. Code P & MSR. A cementitious material with high resistance to sulfate ion corrosion is prepared by adding proper amount of gypsum into the clinker of proper proportion of Portland cement clinker, which is called high sulfate silica cement. High sulfur resistant cement.

- Q: What is acidproof brick?

- Hao Ran acid tile brick structure compact, low water absorption rate, the pH of the medium can be any concentration, with excellent corrosion resistance. And the set pressure, wear resistance, anti permeability, easy cleaning, acid and alkali in one, with excellent performance is widely used in petroleum chemical industry, metallurgy, electric power, chemical, papermaking, pharmaceutical, chemical, food, dairy, juice, electroplating and the tower, tank, tank, tank anti-corrosion engineering, and work in the underground sewers the open ground and other places play an important role.

- Q: The difference between polished tiles and glazed tiles?

- Just because of the surface layer, so the pattern will slowly fade, it looks very old, but the brick does not have this problem, the brick on the market, some does not completely block brick has a pattern, just by the superposition technique, will have almost half the above pattern.

- Q: Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- Acid etching is a chemical cleaning process to remove metal oxide and other impurities from the acid aqueous solution. As the acid and corrosion are more economical and suitable for continuous operation, it is the most effective way to remove the oxide surface of metal surface of large tonnage products. Especially cleaning iron and steel products, such as billets, ingots, steel plates, steel strips, wires, pipes and so on. Can also be used for steel forgings, casting cleaning, rust removal

- Q: What is acid proof tile, acidproof ceramic tile brand introduction?

- Acid resistant tile, each tile in production, have to do product testing

Send your message to us

Acid Resistant Corundum Brick for Linings of High-Temp Industrial Kilns and Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords