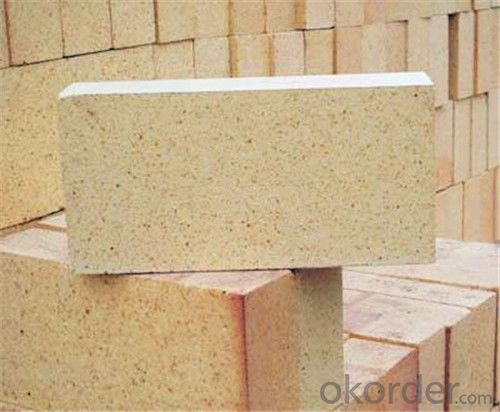

High Alumina Brick with Acid Resistance and Excellent Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acid Resistant Brick Excellent Mechanical Strength

Brief discription for Acid Resistant Brick

CMAX High Insulating Fibre Brick UAL85 are classified according to alumina content ranging from 48% to 95%, manufactured from such mineral as bauxite, corundum, etc. by mixing, press-forming, drying, sintering and machining.

CMAX High Insulating Fibre Brick UAL85 feature stable mechanical strength and thermal shock resistance, with high refractoriness of no lower than 1750 degree.

Advantages for Acid Resistant Brick

◆Low thermal conductivity

◆High refractoriness

◆Excellent acid and base slagging resistance

◆Excellent thermal shock resistance

◆Excellent mechanical strength

Specification/Technical data for Acid Resistant Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

Iamges

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- The difference between the two kinds of high alumina bricks is great. I perennial in Zhengzhou was responsible for the production and sale of colt refractories

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- Quality requirements for aluminium bricks of different grade. 2, high aluminum powder and high alumina aggregate and other materials of reasonable proportion, to reach the production requirements.

- Q: The difference between aluminium refractory and magnesia refractory

- Therefore, the difference between the two is a neutral, one is alkaline, the original product is different naturally.

- Q: What materials are used for roof insulation?

- The other one is inorganic insulation materials, such as Portland, rare earth insulation, the thickness should be 5 cm or more, up to the high cost of auxiliary materials of construction, to reinforce, new inorganic insulation material, the material thickness, on the line of 2-3 cm, direct smear on the top of the house, without auxiliary material, than the price of wool, high aluminum silicate cotton.

- Q: How to reduce porosity of high alumina brick

- High alumina brick used as refractory products in refractory material, has a great application in masonry kilns, insiders pointed out that the quality of high alumina brick general porosity and it has a great relationship! So, how to reduce the porosity of high alumina brick rate is very important!

- Q: The difference between ordinary and diatomite brick refractory brick

- Insulation products made from diatomaceous brick and porous diatomite. The main raw material is natural porous diatomite, and then a small amount of clay and fuel are added. The volume density of diatomite brick was 0.7g/cm3, compressive strength at room temperature is 1 ~ 2MPa, the coefficient of thermal conductivity at 400 C for 0.13 ~ 0.20W/ (M - K), the apparent porosity is greater than 70%, the coefficient of thermal expansion (1280 degrees) 0.9 x 10 - 6 DEG -1, refractoriness is greater than 1250 DEG C. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina bricks, commonly called insulating refractory bricks, also known as insulating refractory bricks. First of all, literally, lightweight aluminum bricks and heavy aluminum bricks are very different in weight. Lightweight high alumina bricks, also called insulated high alumina bricks, are designed for insulation and heat preservation. In normal use, the utility model is not directly contacted with the furnace temperature, and is a refractory brick product which is close to the furnace wall and has the function of heat insulation and heat preservation.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- If the range of softening temperature exceeds the load, the constants of other physical and chemical indexes will also increase or decrease.

Send your message to us

High Alumina Brick with Acid Resistance and Excellent Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords