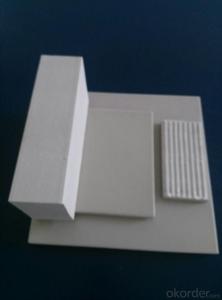

Acid Resistant High Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1222222 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | SIO2 |

| SiO2 Content (%): | ≥ 65 | Al2O3 Content (%): | - | MgO Content (%): | - |

| CaO Content (%): | - | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | - |

| SiC Content (%): | - | Model Number: | Acid-proof brick | Brand Name: | RS |

| Brand: | Rongsheng | Bulk density(g/cm3): | 1.0 | Cold Crushing Strength(Mpa) ≥: | 10 |

| Thermal Conductivity(W/m.k) ≤: | 0.45 | Water Absorption(%) ≤: | 15 | Acid-proof rate(%) ≤: | 98 |

| Service temperature( ℃) ≤: | 1000 | Price: | Factory Outlet | OEM: | Yes |

| Size: | You decide |

Packaging & Delivery

| Packaging Details: | Bricks are packed on wooden pallet and then polyethylene film is placed over it, finally the package is tied up with steel strips. |

| Delivery Detail: | 7 days after receiving deposit or as per requirements |

Acid-resistant Chimney Brick For The Lining Of Furnace

Product Description

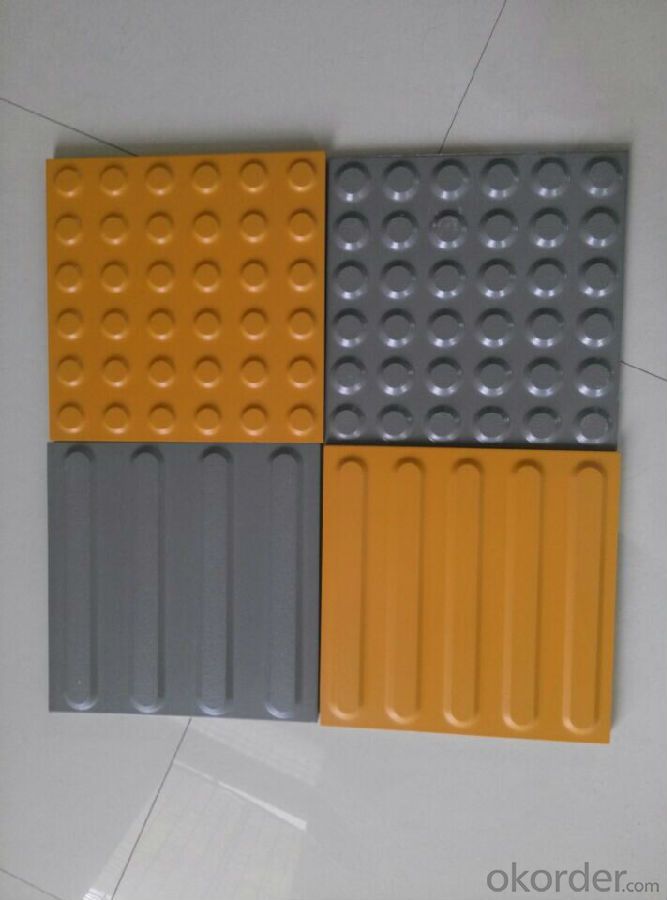

Application For Acid-resistant Chimney Brick:

Acid resistant brick widely used for the flue,chimney lining of thermal power plant, coke oven roof, cold coke tower, storage tank and sieve focal system slip focal slot lining,Anticorrosive device, Acid resistance pool, Acid resistance ground, Wear-resisting ground , etc for thermal electric power, coking, chemical industry.

Feature For Acid-resistant Chimney Brick:

1. Good acid resistant.

2. High strength and Wear resistance.

3. Low water absorption and low apparent porosity.

4. Good eroding proofing and impact resistance.

5. High temperature resistant.

6.Good thermal shock resistance.

7. High mechanical strength.

Technical Index For Acid-resistant Chimney Brick :

| Special acid-proof brick | Lightweight acid-proof brick | |

| Index | ||

| SiO2(%) ≥ | 65 | 65 |

| Bulk Density(g/m³) | 1.6-1.8 | 1.0-1.3 |

| Cold Crushing Strength(Mpa) ≥ | 15 | 10 |

| Thermal Conductivity(W/m.k) ≤ | 0.65 | 0.45 |

| Water Absorption(%) ≤ | 15 | working face 5 |

| Acid-proof rate(%) ≤ | 98 | 97 |

| Service temperature( ℃) ≤ | 1000 | 1000 |

- Q: How to clean the acid brick surface dirt?

- Wash the bricks with a mixture of soap and a little ammonia and turpentine, and make the bricks more lustrous.

- Q: Does the chimney have high acid resistance?

- The acid resistant bricks used for chimney are usually made of custom-made trapezoidal acid proof bricks, and the physical and chemical indexes of acid resistant bricks need to be confirmed according to the chimney's actual emission. At this point, you can consult our kerei refractories.

- Q: How can acid proof cement be used?

- Before construction, metal equipment should be rust removal, decontamination, etc., brick structure should be washed clean, acid resistant cement surface should be first neutralized by acid, washed with water, and then heating drying, generally require less than 4% moisture.

- Q: Consult: water treatment room anticorrosive usable granite and acid resisting brick, these two kinds of material what?

- RZG garnet is almost insoluble in acid insoluble in alkali, common for the diamond 12 face angle of 38 or four surface features can ensure that different crystal polyhedron particles than other material between ordinary circular or elliptical particles can produce voids more suitable, can play a better effect of filtration and antisepsis.

- Q: The difference between acid and heat resistant lightweight castables and acid resisting bricks

- Acid resistant bricks can be customized according to different environments, and resist acid and alkali brick materials of various acids and bases. And pouring materials basically uniform formula, even if a slight adjustment can not solve the strong acid, strong alkali use environment.Acid resistant bricks can be factory mass customization, the cost is slightly lower, while the casting materials need on-site construction, the cost is slightly higher.

- Q: Is it necessary to use sulphate resisting cement in alkaline areas?

- 1. acid can be applied in chemical industry, petroleum, metallurgy, machinery, textile, papermaking, sugar and other industrial equipment in construction engineering, the floor in the equipment foundation, acid corrosion and acid storage tank, chimney lining workshop, building waste and gaseous acid corrosion, can be prepared by acid resistant clay masonry brick acid and board; can be mixed with acid and coarse aggregate (gravel), fine aggregate (sand) acid and preparation of acid resistant concrete.2. can not be used by hydrofluoric acid, fluosilicate, 300 degrees above phosphoric acid and advanced fatty acids and oleic acid, palmitic acid, and alkaline salt erosion engineering. When used in the food industry, sodium fluoride in sodium fluosilicate should be tested to prove that it is not harmful to humans.

- Q: Which acid proof tile factory is reliable in quality?

- We all know that the main component of acid resistant ceramic which is silica, liangdun acid resistant ceramic material is used by Shanxi local quartz stone, containing a large number of silicon content, acid resistant tiles can thus produced corrosion.

- Q: What brand does acidproof ceramic tile ten big famous brands have?

- Now let's introduce in detail of acid resistant ceramic ten brand-name what brand, in fact the ten major brands of ceramic tile manufacturers have to choose acidproof tile, tile acid, these ten brands of ceramic tile manufacturers to be sure, but the ten tile brand ranking of two, you can go to compare, look at the two ten famous brand rankings have what different tiles.

- Q: 98% acid tank cofferdam can use acid resistant brick?

- The operation temperature of some hot oil pumps in hydrogenation unit is higher, which is higher than the spontaneous ignition point of oil products. If there is leakage, it is prone to fire accidents. Therefore, the operation should pay attention to the operation of hot oil pump, pay attention to pump body, sealing and so on whether there is leakage, if leakage should be dealt with immediately.

- Q: What is acid proof tile, acidproof ceramic tile brand introduction?

- Among them, the detection of acidity and alkalinity is one of them. The state has relevant standards.Among them, the inspection standard of glazed tiles is different from that of polished tiles.

Send your message to us

Acid Resistant High Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1222222 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords