Acid Resistant Brick with Strong Acid and Alkali Resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

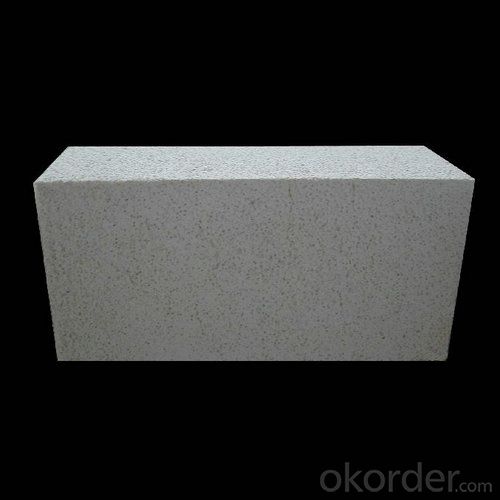

Description of Acid Resistance Brick

CMAX acid resistance brick is specially used as lining in reaction tower of chemical plants, fertilizer factories and sulfuric acid industries or inside the corrosion-resistance pool and ditch.

Features of Acid Resistance Brick

Strong acid and alkali resistance

Size available as customer’s requirement

Applications of Acid Resistance Brick

Acid Resistance Brick is widely used in corrosion-resisting liner of petroleum, chemical industry, chemical fertilizer, food, chemical fiber, laboratory, pharmacy, papermaking, generate electricity, smelt, electroplating room, and the inner corrosion-resisting lining of tower, pool, pot, tank, etc. Acid Resistance Brick is also used for sewage conduit and open-air floor.

Specifications of Acid Resistance Brick

clay refractory brick | ZCN-42 | GN-42 |

AL2O3 /% | ≥42 | ≥42 |

Fe2O3 /% | ≤1.6 | ≤1.7 |

Refractoriness /°C | ≥1750 | ≥1750 |

Apparent porosity/ % | ≤15 | ≤16 |

Cold crushing strength/ Mpa | ≥58.8 | ≥49.0 |

Refractoriness under load/ °C | ≥1450 | ≥1430 |

Reheating Linear Change(1450°C,3h)/% | 0~-0.2(3h) | 0~-0.3(3h) |

Permeability | This test must be conducted. The data of test shall be included in the quality certificate. | |

Images of Acid Resistance Brick

FAQ of Acid Resistance Brick

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

CNBM offer a range of refractory and insulation products. We provide refractory bricks, monolithic refractories as well as ceramic fiber products. And On your given shapes, drawings or description, we are producing refractories with all sizes and shapes, resistant to temperature from 800 °C till 1800 °C, using various machines and equipments for cutting, grinding, drilling, polishing, shaping processes.

Every refractory product by CNBM is of superior quality. Lesser refractory products can not approach. CNBM utilizes proprietary testing methods, testing for chemical content, density, apparent porosity, cold crush strength and modulus of rapture. With stringent quality control, you can count on CNBM products to exceed refractory industry standards and your expectations.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: The acid resistance is 99.4%. Is this acid resistant brick very bad?

- Do not recommend you buy the acid resistance of substandard tile, tile acid refers to the acid resistance of 99.8 according to the national standard

- Q: What are the standard specifications for acid resisting bricks?

- Because of the different acid and alkali environment, the acid resisting ceramic tile has different requirements on the degree of acid and alkali, so it is necessary to make the price reasonable at the time of construction,

- Q: What is acid proof brick

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, made by high temperature oxidation corrosion resistant materials, resistant to high pH, low water absorption, is not easy to be oxidized at room temperature, the media can not easily be pollution performance, except hydrofluoric acid and hot phosphoric acid, the temperature of chlorine saline, hydrochloric acid, sulfuric acid and nitric acid and at room temperature in any concentration of alkali, corrosion resistance are excellent.

- Q: Is it necessary to use sulphate resisting cement in alkaline areas?

- 1. acid can be applied in chemical industry, petroleum, metallurgy, machinery, textile, papermaking, sugar and other industrial equipment in construction engineering, the floor in the equipment foundation, acid corrosion and acid storage tank, chimney lining workshop, building waste and gaseous acid corrosion, can be prepared by acid resistant clay masonry brick acid and board; can be mixed with acid and coarse aggregate (gravel), fine aggregate (sand) acid and preparation of acid resistant concrete.2. can not be used by hydrofluoric acid, fluosilicate, 300 degrees above phosphoric acid and advanced fatty acids and oleic acid, palmitic acid, and alkaline salt erosion engineering. When used in the food industry, sodium fluoride in sodium fluosilicate should be tested to prove that it is not harmful to humans.

- Q: Which acid proof tile factory is reliable in quality?

- We all know that the main component of acid resistant ceramic which is silica, liangdun acid resistant ceramic material is used by Shanxi local quartz stone, containing a large number of silicon content, acid resistant tiles can thus produced corrosion.

- Q: What is acidproof brick?

- The main component of acid resistant brick is silica, and Hao Ran acid resistant bricks are made of imported raw materials and imported color materials by high temperature firing.

- Q: Construction method of acid proof brick

- Construction methodLining adhesive layer, mortar protection layer: lining carbon brick before, in the bottom board first put a layer of delta =3mm cement whole surface layer, in order to protect the lining layer and avoid mortar joint layer appear blind seam, curing at normal temperature after masonry.Positioning, layout and layout: according to the bottom of the groove size, first play the central cross line, then positioning, line, according to the line for typesetting, painting, cutting and numbering.Lining procedures: masonry procedures from low to high, the first base, the rear wall, the Yin angle, the facade to suppress the plane, Yang Kok plane cover the facade.Masonry method: the bottom and wall are all made by squeezing, kneading and extruding, and they are made by line by line, layer by layer, block by block.The prepared mortar evenly scraping on the three surfaces of carbon brick (i.e., on the back end, and then squeeze (side), rubber hammer) is dense, the ash seam and the combined layer clay full, squeeze out excess clay to eradicate. The surface shall be made of flat and vertical, rows and rows, and the seams between floors and layers shall be staggered.

- Q: The difference between polished tiles and glazed tiles?

- The brick is a brick block pattern, glazed tile surface is a layer of glaze, the following are the embryo is yellow brick, looks like that, for a long time, this layer of glaze will slowly worn away

- Q: What is acid proof tile, acidproof ceramic tile brand introduction?

- Among them, the detection of acidity and alkalinity is one of them. The state has relevant standards.Among them, the inspection standard of glazed tiles is different from that of polished tiles.

- Q: How much is one square meter of acidproof tile?

- Acid resistant brick: resistance to pressure, corrosion resistance, easy to clean, acid and alkali; acid resistant tile prices generally around 40 yuan a square meter!

Send your message to us

Acid Resistant Brick with Strong Acid and Alkali Resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords