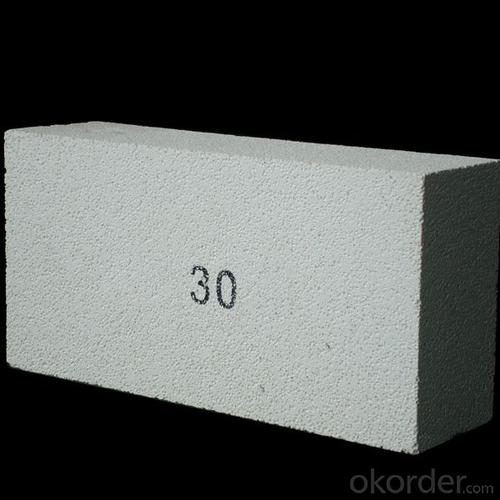

High-Performance Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Pcs m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick

Our insulating firebricks are classified under temperature range from 1300℃ to 1700℃.Our insulating fire bricks are manufactured from high purity alumina clay.

Feature of Insulating Fire Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating Fire Brick

Our insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data of of Insulating Fire Brick

- Q: Are insulating fire bricks suitable for use in glass melting furnaces?

- Depending on the requirements of the furnace and the type of glass being melted, insulating fire bricks may be a suitable option for glass melting furnaces. These fire bricks are constructed from lightweight materials that have low thermal conductivity, enabling them to effectively retain heat and minimize energy loss in the furnace. This, in turn, can enhance the furnace's energy efficiency and decrease operational expenses. Nevertheless, it is essential to take into account the temperature and atmosphere within the glass melting furnace when selecting the appropriate insulating fire bricks. Glass melting furnaces function at extremely high temperatures, often surpassing 1500°C (2732°F). Some insulating fire bricks may not be capable of enduring such elevated temperatures and could deteriorate or even melt under these circumstances. Furthermore, the atmosphere within the glass melting furnace can influence the suitability of the insulating fire bricks. Certain types of these fire bricks may interact with specific gases or chemicals present in the furnace atmosphere, leading to degradation or contamination of the molten glass. Hence, it is crucial to choose insulating fire bricks that are compatible with the precise atmosphere and conditions within the glass melting furnace. To summarize, insulating fire bricks can be appropriate for use in glass melting furnaces, but careful consideration must be given to their temperature resistance and compatibility with the furnace atmosphere. Seeking guidance from specialists or suppliers who specialize in refractory materials for glass melting furnaces can help ensure the appropriate selection of insulating fire bricks for optimal furnace performance and glass quality.

- Q: Are insulating fire bricks resistant to fluorine gas?

- Yes, insulating fire bricks are generally resistant to fluorine gas due to their refractory properties and ability to withstand high temperatures and chemical corrosion.

- Q: Are insulating fire bricks resistant to sound transmission?

- Insulating fire bricks, also known as refractory bricks, are primarily designed to withstand high temperatures and provide thermal insulation. While they are effective in reducing heat transfer, they are not specifically designed to resist sound transmission. Insulating fire bricks are made from materials such as clay, alumina, and silica, which are chosen for their ability to withstand high temperatures. These materials are dense and have a low porosity, which helps to prevent heat from passing through the bricks. However, sound waves can easily pass through solid materials, including insulating fire bricks, unless additional measures are taken to reduce sound transmission. To effectively reduce sound transmission, other soundproofing methods should be used in conjunction with insulating fire bricks. These can include adding additional layers of acoustic insulation or using sound barriers such as mass-loaded vinyl or acoustic panels. In summary, while insulating fire bricks are excellent for thermal insulation, they are not inherently resistant to sound transmission. Additional soundproofing measures should be taken to effectively reduce noise transmission in a given space.

- Q: Are insulating fire bricks suitable for use in high-temperature chimneys?

- Yes, insulating fire bricks are suitable for use in high-temperature chimneys. These bricks are specifically designed to withstand extreme temperatures and provide excellent insulation properties. They have a high melting point and low thermal conductivity, which allows them to effectively retain heat and prevent it from escaping through the chimney walls. This helps in maintaining a high temperature inside the chimney, which is crucial for efficient combustion and proper functioning of the chimney. Additionally, insulating fire bricks are lightweight and durable, making them an ideal choice for constructing chimneys that are exposed to high temperatures.

- Q: Are insulating fire bricks suitable for insulation in boilers?

- Yes, insulating fire bricks are suitable for insulation in boilers. Insulating fire bricks are specially designed to withstand high temperatures and provide excellent thermal insulation, making them ideal for use in boilers. They help to reduce heat loss, improve energy efficiency, and enhance the overall performance of the boiler.

- Q: Can insulating fire bricks be used in the construction of reheat furnaces?

- Yes, insulating fire bricks can be used in the construction of reheat furnaces. These bricks are designed to have high insulating properties, which helps to minimize heat loss and improve energy efficiency in the furnace. Additionally, their lightweight nature makes them easier to handle and install.

- Q: Can insulating fire bricks be used in fireplace construction?

- Indeed, fireplace construction can make use of insulating fire bricks. These bricks are specifically crafted to endure extreme temperatures and offer exceptional insulation, rendering them appropriate for lining fireplaces. By retaining heat and impeding heat transfer to the surrounding structure, they enhance the fireplace's efficiency while diminishing the likelihood of harm to adjacent materials. Moreover, the lightweight and manageable nature of insulating fire bricks make them an excellent choice for constructing fireplaces.

- Q: Can insulating fire bricks be used in DIY projects?

- Certainly, DIY projects can make use of insulating fire bricks. With their lightweight and superb thermal insulation properties, these bricks prove suitable for a range of applications. They find common use in the construction of wood-fired ovens, fire pits, kilns, and even forge walls. Insulating fire bricks possess the ability to endure high temperatures and resist thermal shock, thus providing a dependable option for heat-resistant structures crafted by DIY enthusiasts. Furthermore, they offer ease of cutting and shaping, enabling customization to align with specific project requirements.

- Q: Are insulating fire bricks resistant to hydrofluoric acid?

- Yes, insulating fire bricks are resistant to hydrofluoric acid.

- Q: What is the lifespan of insulating fire bricks?

- The lifespan of insulating fire bricks can vary depending on various factors such as the quality of the bricks, the conditions they are exposed to, and the usage. However, on average, insulating fire bricks can last anywhere from 5 to 20 years.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 10.00% Northern Europe 30.00% North America 30.00% Eastern Asia 5.00% Africa 10.00% Southeast Asia 15.00% Western Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 10 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 16,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High-Performance Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Pcs m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords