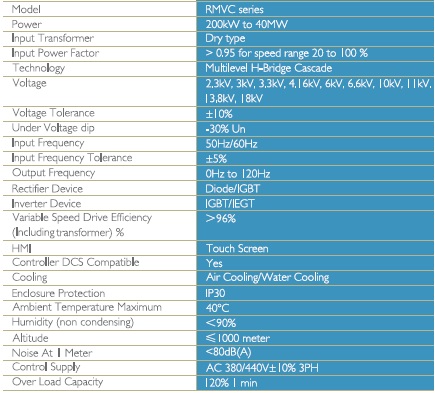

High Medium Voltage Drive 4.16KV 1100KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q: How do I protect the inverter when the three-phase two-pole motor is running?

- Three-phase two-pole motor running inverter protection, should be based on the protection of tips, check the corresponding manual to deal with. When the inverter protection has a corresponding protection tips (such as over-current, over-voltage, speeding, stall ... ... etc.), the product manual will generally give the corresponding protection tips. According to these measures to check, deal with, you can solve the problem.

- Q: How is the notebook with a power adapter?

- Refer to the following factors when purchasing: Choose the brand: The principle is to choose the same type with the brand, if not, it can only find other brands. Now online to sell a lot of notebook power adapter are cut corners of the substandard products, the normal use of what should be no problem, once the accident will burn your laptop, save dozens of pieces but burn thousands of pieces of notebook worth the candle. (Such as the actual only 19V3.42A, but the standard 19V4.74A, this will lead to a very slow charge, and even damage the battery and laptop computers. There are some protection removed, this more horrible, there Accidentally burn the laptop.

- Q: What is the laptop power adapter? Is it the battery?

- Power adapter is inserted in the plug-in power cord connected to the black, rectangular cube that thing, after the power adapter into a notebook acceptable voltage,

- Q: What are the differences and links between the soft starters and the frequency converters, and their respective principles and uses?

- The soft starter is activated by adjusting the voltage and current, and the frequency converter starts the motor by changing the frequency of the power supply. The soft starter can theoretically smooth and gradually start the motor to the maximum speed. No impact current (ordinary start-up current is 6-7 times the rated current) The inverter is best suited for tap water and fans, etc. The soft starter is not suitable for everything except for heavy load start.

- Q: What is the single axis of the inverter and multi-axis applications

- Inverter is mainly used for AC motor (asynchronous motor or synchronous motor) speed adjustment, is recognized as the AC motor the best and most promising speed control program, in addition to excellent speed performance, the inverter is also significant Energy-saving effect, is the enterprise technological transformation and product upgrading of the ideal speed control device. Since the introduction of China since the 80s of last century, the frequency converter as energy-saving applications and speed of process control more and more important automation equipment, has been rapid development and wide application.

- Q: ASUS power adapter Acer can use it

- See whether the power adapter is suitable for notebook use, the following three conditions for reference: 1. The output voltage of the adapter is the same as that of the notebook.

- Q: Octopus AC Servo motor can be driven with ordinary inverter?

- If it is asynchronous motor, then take the power, voltage matching ordinary inverter drive no problem, you only need to enter the appropriate parameters, such as current, power size and other parameters, and then off-line parameters from the adjustment (if the vector control run), you can run

- Q: Who knows how the inverter is calculated?

- The synchronous speed of the two-pole motor is 3000 rpm,

- Q: 18: 5 kilowatts bipolar multi-pole pump motor with inverter

- Under normal circumstances, with 15KW inverter on it.

- Q: What is the meaning of the bipolar polarity in the inverter ah There is a +10V signal input is a -10V What is the meaning of ah?

- Bipolar input is positive and negative. Bipolar input is generally used to directly through the external reference or potentiometer to achieve the motor forward and reverse switching, without having to switch all the way to switch the signal (switch).

Send your message to us

High Medium Voltage Drive 4.16KV 1100KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords