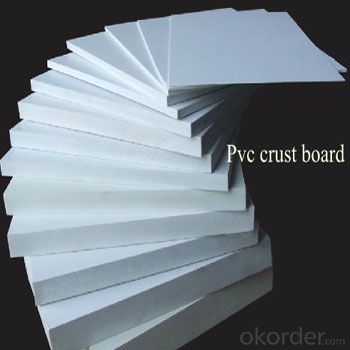

High density plastic foam 1mm thick sell black pvc foam sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High density plastic foam 1mm thick sell black pvc foam sheet

We are specialized manufacturing PVC foam board.There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful servise.And now we have 7 production line for PVC foam board.

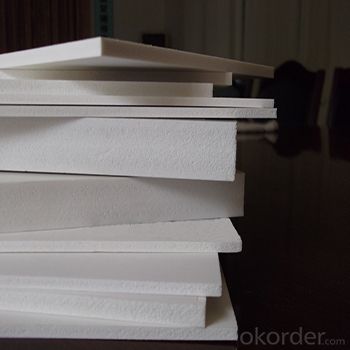

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

Product Description

1. Waterproof and mould proof

2. Widely used in kitchen and washroom cabinet

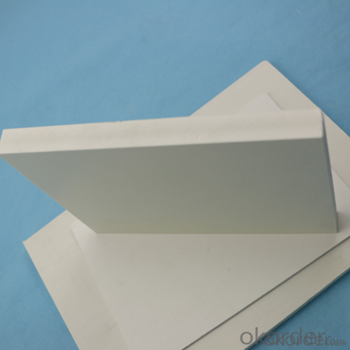

3. Thickness from 1mm to 25mm, different density

4. Width: 1220mm

5. Length: 2440mm or as per your requirement

6. Thickness: From 1mm to 33mm

7. Density: from 0.45 to 0.9 mm

Features

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

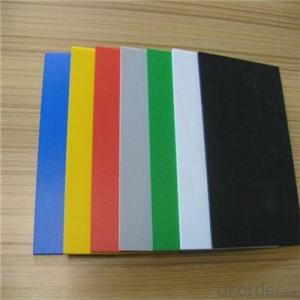

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

- Q: I would appreciate anyones help on this.I have to have a custom high-detailed graphic printed onto a sheet of plastic measuring 25 and 3/4 by 27. I'm assuming I will need a specialist service, but I'm not really too sure where to start, or how much this will cost me. This will be a custom made banner for an arcade machine, if anyone's interested. Can anyone direct me towards services, or even give me an idea of prices? I live in Essex, UK, if anyone can find somewhere local, I would greatly appreciate it!Thanks guys!-Kirsty

- check okorder

- Q: How do you type on a plastic board?

- The printing process is divided into the transfer film printing and transfer printing of two parts, transfer film printing using dot printing (resolution of 300dpi), the pattern of pre printed pattern on the film surface, the level of rich, colorful, the myriads of changes, small color difference, good reproducibility, can achieve the design requirements of the effect, and is suitable for large mass production;

- Q: Are plastic sheets resistant to warping under heat?

- Yes, plastic sheets are generally resistant to warping under heat.

- Q: Can plastic sheets be used in medical applications?

- Yes, plastic sheets can be used in medical applications. They are commonly used in medical devices, such as face shields, protective barriers, and packaging for medical equipment and supplies. Plastic sheets offer various advantages including flexibility, durability, and ease of sterilization, making them suitable for a wide range of medical uses.

- Q: What is the lifespan of plastic sheets?

- The lifespan of plastic sheets can vary depending on various factors such as the type of plastic, exposure to sunlight, temperature fluctuations, and overall usage. However, plastic sheets can typically last for several years to decades if properly cared for and maintained.

- Q: I told a co-worker my wife is 5 months pregnant and days later he comes and gives me three old diapers and a used plastic sheet. I feel insulted. Am i looking too deep into it? Why would you give someone who is 4 months away from having their baby old diapers and used palstic sheet?

- I don't see anything wrong with it. Cloth diapers are expensive, and he may have given you a sample pack. And I don't know what you mean by plastic sheet... changing pad maybe? IF they were dirty diapers obviously I would be offended, but I would appreciate a gift of used cloth diapers. They are worth about 50% of the cost new. Sounds like he was offering you a gift. Also nothing wrong with old disposable diapers. They don't have an expiration date. That is what is great about plastic. Why do you feel insulted? There are many reasons why someone would give that as a gift. They may be environmentalist, and can't put plastic in the trash, so it must be saved as a gift for someone else having a baby. Or they might be kinda broke, or maybe the guys wife said hey, give him this!

- Q: ex. 10 ml black plastic

- very confusing problem. try searching onto search engines like google. this could actually help!

- Q: Can plastic sheets be used for storm windows?

- Yes, plastic sheets can be used for storm windows. They are a cost-effective alternative to traditional glass storm windows and provide insulation against drafts, rain, and noise. Plastic sheets are lightweight, easy to install, and can be removed during warmer seasons.

- Q: Are plastic sheets resistant to warping from high temperatures?

- No, plastic sheets are not generally resistant to warping from high temperatures.

- Q: Can plastic sheets be used for bird feeders?

- Yes, plastic sheets can be used for bird feeders. They can be easily shaped and molded into different sizes and designs, making them a versatile material for creating bird feeders. Additionally, plastic sheets are durable and weather-resistant, making them suitable for outdoor use.

Send your message to us

High density plastic foam 1mm thick sell black pvc foam sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords