Plastic Sheets - 3mm Thick Sell Black/High Density Waterproof PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We are packaging foam board manufacturer, packaging foam board is becoming the substitution of wood in many fields such as AD and Decoration. We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer. It made through foaming and pressing into shape with additives. The main material is PVC. So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

PVC Foam board/sheet Applications

1. exhibition desk, Shelve in supermarket

2. Advertisemen Board and sign board

3. the advertisement sheet for printing,engraving,cutting,sawing

3. Architectural decoration and upholstery

4. decoration for partition wall and shopwindows

FAQ:

(1).How can i get the sample?

If you need samples, we can make as per your request. The samples available for free. And you should pay for the transportation freight.

(2).How long can i expect to get the sample?

The samples available as you ask in 1 days. The samples will be sent via express and arrive in 5~7 days.

(3).Can we have our Logo or company name to be printed on your package?

Sure. Your Logo can be putted on the package by printing or sticker.

Product Description

Our pvc foam board/sheet size

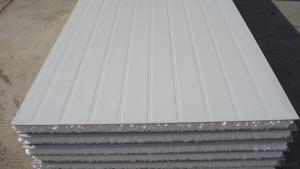

Width: 1250mm-2050mm,2050mm in max.

Length: Any length.

standard size :1220*2440mm,1560*3050mm,2050*3050mm

NOTE: we can make other size according customer requirment

MOQ | 100PCS |

Delivery | 6-9days after confirm your order |

pvc foam board/sheet description

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm and so on |

3 | Thickness | 1~30mm |

4 | Density | 0.4~0.8g/cm3 |

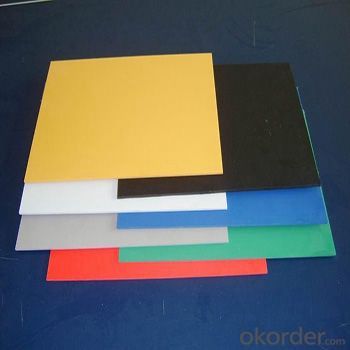

6 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

7 | Executive standard | QB/T 2463.1-1999 |

8 | Certificate | ISO9001 |

9 | Weldable | Yes |

10 | Foam Process | Celuka |

11 | Packing | Carton box or wooden pallet packing |

12 | production capability | 10000 pcs per month |

13 | Life Span | >50 years |

14 | Flame retardance | self-extinguishing less than 5 seconds |

- Q: Can plastic sheets be used for window insulation?

- Yes, plastic sheets can be used for window insulation. They can help reduce heat loss and drafts by creating an additional layer of insulation over windows, preventing cold air from entering and warm air from escaping.

- Q: Does anyone have any suggestions?

- Your kitty can scratch through the plastic. I would suggest a scratching post. There is also a spray that you can apply to the couch to try to prevent scratching.

- Q: Plastic sheet capable of bending 90 degrees by hand

- Materials are transparent and bent, 90 degrees broken K-resin, polycarbonate, PETG, PCTA, transparent PP, PBT, transparent ABS transparent materials, range of choice

- Q: Can plastic sheets be used for chemical storage containers?

- Yes, plastic sheets can be used for chemical storage containers. However, it is important to use chemically resistant and compatible plastic materials that are specifically designed for storing the intended chemicals.

- Q: Can plastic sheets be bent or molded into shapes?

- Yes, plastic sheets can be bent or molded into various shapes by applying heat or pressure.

- Q: What types of plastics are used to make plastic sheets?

- There are several types of plastics used to make plastic sheets, including polycarbonate, acrylic, polyethylene, and polypropylene.

- Q: where can i find clear large plastic bags that big in size that i can put my bed sheets in?

- Honestly, if you are going to poke fun at something so serious and everlasting, I don't think you actually believe in the Rapture. So, you may not be in the Rapture either, because of your taunting, so keep every tangible thing you have on earth, you'll need it for later.

- Q: What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q: For example, could you use a banana leaf or some other form of cover other than a plastic bag, tarp, or man-made material?

- Well, you'd need it to be non porous as smooth as possible, but honestly the places you'd want a solar still to survive with don't give you much to work with that you didn't bring in yourself. Sometimes manufactured items are really convenient, I mean most of the Amerindians with contact to European steel found it so much better than stone that they lost the ability to make stone tools within a few generations.

- Q: Can plastic sheets be used for protective barriers?

- Yes, plastic sheets can be used for protective barriers. They are often used as a cost-effective and versatile solution to protect against physical, chemical, or biological hazards. Plastic sheets can offer transparent visibility, resistance to impact, and easy installation, making them suitable for various applications such as in healthcare settings, construction sites, or industrial environments.

Send your message to us

Plastic Sheets - 3mm Thick Sell Black/High Density Waterproof PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords